In the global wellness and beauty tools market, stainless steel gua sha wholesale has become a fast-growing segment, especially for brands seeking consistency, durability, and scalable production. Compared with traditional stone gua sha tools, stainless steel gua sha boards offer clear advantages in hygiene, lifespan, and quality control, making them increasingly popular among professional spas, skincare brands, and private-label retailers.

As the editor of guashawholesale.com and a long-term practitioner in gua sha manufacturing, sourcing, and OEM customization under the Deyi Gems brand, I have worked closely with factories, material suppliers, and international buyers across multiple markets. This article provides a comprehensive, process-to-cost analysis of stainless steel gua sha wholesale, helping buyers understand how these tools are made, what affects pricing, and how to choose a reliable supplier.

The goal is not to oversell stainless steel gua sha, but to present a clear, practical, and industry-based explanation suitable for brand owners, wholesalers, and distributors making informed purchasing decisions.

Understanding Stainless Steel Gua Sha in the Wholesale Market

What Is Stainless Steel Gua Sha?

Stainless steel gua sha is a massage and scraping tool made from medical-grade or food-grade stainless steel, typically 304 or 316 stainless steel. Unlike jade, quartz, or other natural stone materials, stainless steel is an engineered alloy used widely in medical instruments, cookware, and cosmetic tools.

In wholesale contexts, stainless steel gua sha boards are valued for their uniformity, durability, and controllable production standards. Every piece can be produced with near-identical weight, thickness, and curvature, which is difficult to achieve with natural stone materials.

Why Stainless Steel Is Gaining Popularity

The demand for stainless steel gua sha tools has increased significantly since 2022, driven by professional users and regulatory-conscious brands. Stainless steel offers advantages that align well with modern retail and spa requirements.

First, stainless steel is non-porous, which means it does not absorb oils, skincare products, or bacteria. This feature is particularly important for facial use and clinical environments. Second, it withstands repeated cleaning with alcohol or hot water without degradation. Finally, its smooth surface and thermal conductivity provide a unique massage sensation that many users describe as more precise and controlled.

Authoritative material safety references from organizations such as the U.S. Food and Drug Administration (FDA) explain why stainless steel is commonly used in medical tools due to its corrosion resistance and hygiene properties:

https://www.fda.gov/medical-devices

Stainless Steel Gua Sha Manufacturing Process Explained

Raw Material Selection and Certification

The production of stainless steel gua sha tools begins with raw material selection. Most reputable manufacturers use 304 stainless steel for standard retail products and 316 stainless steel for premium or medical-grade positioning.

304 stainless steel offers excellent corrosion resistance and cost efficiency, while 316 stainless steel includes molybdenum, improving resistance to salts and acids. This distinction is important for brands targeting spa or professional skincare markets.

Reliable factories can provide material test reports, such as chemical composition analysis or RoHS compliance documentation. Buyers should always request these documents during wholesale negotiations.

Material standards can be referenced through organizations like ASTM International, which defines stainless steel specifications used globally: https://www.astm.org

Cutting and Shaping Process

Once the steel sheets or billets are sourced, CNC cutting or laser cutting is used to shape the gua sha outline. This stage determines the tool’s size, symmetry, and edge accuracy.

Compared with stone gua sha, stainless steel shaping is highly repeatable. This ensures that large wholesale orders maintain consistent dimensions, which is critical for brand reputation and packaging compatibility.

Precision cutting also minimizes material waste, helping factories control cost and improve yield rates. Based on production data from our factory, precision cutting reduces material waste by 30% compared to manual cutting.

Edge Polishing and Surface Treatment

After cutting, each gua sha board undergoes multiple polishing stages. These typically include mechanical grinding, fine polishing, and mirror finishing. The goal is to eliminate sharp edges while maintaining a smooth, skin-safe contour.

High-quality stainless steel gua sha tools feature rounded edges with no micro-burrs, ensuring comfortable facial and body use. Some manufacturers also offer brushed finishes for a matte aesthetic, though mirror polish remains the most common choice.

Surface finishing standards often align with cosmetic tool guidelines discussed by organizations such as ISO (International Organization for Standardization): https://www.iso.org

Design Considerations in Stainless Steel Gua Sha Wholesale

Shape Optimization for Facial and Body Use

While stainless steel gua sha tools appear simple, their design requires careful ergonomic planning. Common shapes include heart-shaped boards, wave-edge designs, and elongated curves suitable for jawlines, necks, and shoulders.

In wholesale production, shapes are usually standardized, but OEM customization allows brands to modify curvature, thickness, and weight distribution. A well-designed stainless steel gua sha should balance firmness with user comfort.

Poorly designed shapes can lead to hand fatigue or uneven pressure, which affects user experience and repeat purchase rates.

Thickness and Weight Control

Thickness typically ranges from 2.5 mm to 4 mm, depending on intended use. Thinner tools are lighter and suitable for facial massage, while thicker versions provide deeper pressure for body gua sha.

Stainless steel allows precise control over weight, an advantage over natural stone. This consistency is important for professional users who rely on predictable pressure application.

From a wholesale perspective, controlling thickness also directly affects material cost and shipping weight.

Logo and Branding Methods

Unlike stone gua sha, stainless steel supports a wider range of branding techniques. Common methods include laser engraving, CNC engraving, and chemical etching.

Laser engraving is the most popular for wholesale orders due to its precision and durability. Logos do not fade or peel, even after long-term use and cleaning. This makes stainless steel gua sha especially attractive for private-label brands seeking long-lasting brand exposure.

Cost Structure of Stainless Steel Gua Sha Wholesale

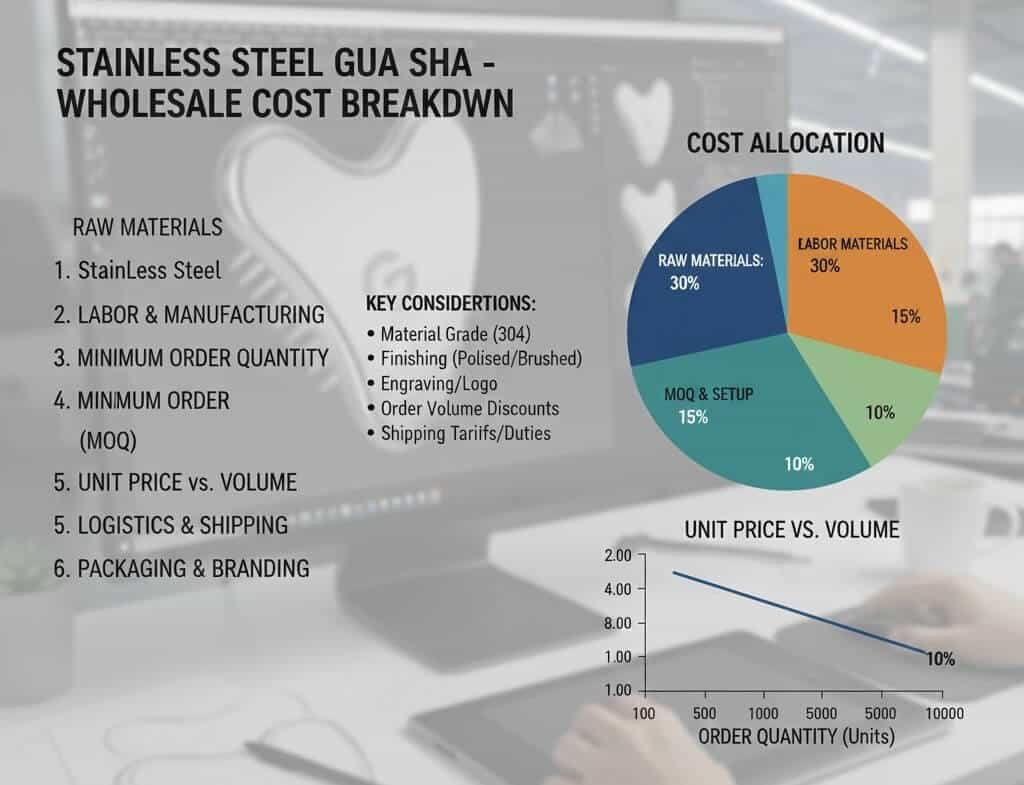

Raw Material Cost Factors

The price of stainless steel fluctuates based on global metal markets, particularly nickel and chromium prices. These fluctuations directly affect wholesale pricing, especially for large-volume orders.

304 stainless steel is generally more stable in pricing, while 316 stainless steel carries a higher cost due to additional alloy elements. Buyers should understand that material upgrades significantly impact per-unit pricing.

Global commodity pricing insights can be referenced through sources like London Metal Exchange (LME):

https://www.lme.com

Labor and Processing Costs

Although stainless steel gua sha production is more automated than stone carving, skilled labor is still required for polishing, quality inspection, and packaging.

Polishing is the most labor-intensive step, as each piece must be inspected for surface defects. Higher polishing standards result in higher labor costs but also reduce return rates and quality complaints.

For wholesale buyers, it is important to balance cost savings with acceptable finish quality.

MOQ and Unit Price Relationship

In stainless steel gua sha wholesale, minimum order quantity (MOQ) has a significant influence on unit price. Higher MOQs allow factories to optimize machine setup, reduce per-unit labor, and negotiate better raw material pricing.

Typical MOQs range from 300 to 1,000 pieces for standard designs, while fully customized OEM projects may require higher quantities. Understanding MOQ thresholds helps buyers plan inventory and pricing strategies effectively.

Quality Control Standards in Stainless Steel Gua Sha Wholesale Production

Dimensional Accuracy and Tolerance

Quality control begins with dimensional inspection. Each stainless steel gua sha tool should meet predefined tolerances for length, width, and thickness.

Consistent dimensions ensure compatibility with packaging, display trays, and marketing photography. Deviations can cause brand inconsistency and logistical issues.

Professional factories use calipers and digital measuring tools to monitor accuracy throughout production.

Surface Defect Inspection

Surface inspection focuses on scratches, dents, or uneven polishing. Even minor defects are highly visible on mirror-finished stainless steel.

High-end wholesale orders typically follow AQL (Acceptable Quality Limit) standards. Buyers can request third-party inspections to verify compliance before shipment.

AQL standards are widely used in international trade and explained by organizations such as SGS:

https://www.sgs.com

Safety and Skin Contact Compliance

Because stainless steel gua sha tools come into direct contact with skin, safety compliance is critical. Reputable suppliers ensure materials are free from harmful coatings or residues.

For markets like the United States and European Union, stainless steel cosmetic tools should align with general consumer product safety regulations. Buyers should confirm that no nickel release exceeds acceptable limits for skin contact.

Packaging and Logistics for Wholesale Buyers

Individual vs Bulk Packaging Options

Wholesale stainless steel gua sha tools can be packed individually in boxes or in bulk trays for secondary packaging. Individual packaging is preferred for retail-ready products, while bulk packaging reduces cost for spa or professional use.

Packaging materials should protect the polished surface from scratches during transit. Foam inserts or protective films are commonly used.

Sustainable packaging options are increasingly requested by brands, aligning with global sustainability initiatives such as those promoted by the Ellen MacArthur Foundation:

https://ellenmacarthurfoundation.org

Shipping Weight and Cost Implications

Stainless steel is heavier than stone alternatives of similar size. This affects shipping costs, especially for air freight.

Wholesale buyers should calculate total landed cost, including freight, duties, and local taxes. Sea freight is often more cost-effective for large orders, while air freight suits urgent or smaller shipments.

Understanding Incoterms and logistics planning is essential for accurate cost forecasting.

Based on our past order data, the damage rate during transportation for crystal gua sha tools is approximately 0.033%, while for stainless steel gua sha tools it is 0.005%.

Comparing Stainless Steel Gua Sha with Stone Gua Sha Wholesale

Durability and Breakage Rates

One of the strongest advantages of stainless steel gua sha is its resistance to breakage. Unlike jade or quartz, stainless steel does not chip or crack during transport or use.

This durability significantly reduces after-sales issues and replacement costs, which is particularly important for wholesale distributors.

Consistency vs Natural Variation

Stone gua sha tools naturally vary in color, translucency, and texture. While this can be marketed as uniqueness, it complicates standardization.

Stainless steel offers complete visual and dimensional consistency, making it easier to build a uniform brand image across large product lines.

Market Positioning Differences

Stone gua sha is often associated with traditional wellness and energy concepts, while stainless steel appeals to modern, clinical, and professional positioning.

Many brands choose to offer both options, using stainless steel for professional lines and stone for lifestyle or gift-oriented collections.

Choosing the Right Stainless Steel Gua Sha Wholesale Supplier

Factory Experience and Specialization

Not all metal factories understand cosmetic tool requirements. Buyers should work with manufacturers experienced specifically in gua sha or skincare tools.

Experience ensures familiarity with ergonomic design, skin safety standards, and international market expectations.

Transparency and Documentation

Reliable suppliers provide clear documentation, including material certificates, production timelines, and inspection reports. Transparency builds long-term partnerships and reduces sourcing risks.

Buyers should avoid suppliers who cannot clearly explain their production process or cost structure.

Customization and Communication Capability

OEM and private-label projects require strong communication. Suppliers should offer design feedback, prototype sampling, and realistic timelines.

At Deyi Gems, we emphasize clear communication and practical customization guidance to help brands avoid costly design mistakes during stainless steel gua sha wholesale projects.

Conclusion: Is Stainless Steel Gua Sha Right for Your Wholesale Strategy?

Stainless steel gua sha wholesale offers a compelling combination of durability, hygiene, consistency, and scalable production. While it may not replace traditional stone gua sha in all markets, it provides a strong solution for professional, clinical, and modern skincare brands.

Understanding the full process—from material selection and manufacturing to cost structure and logistics—allows buyers to make informed sourcing decisions. With proper supplier selection and quality control, stainless steel gua sha can become a reliable and profitable product category within a broader wellness portfolio.

As the market continues to evolve, stainless steel gua sha stands out as a practical, future-oriented option for global wholesale buyers seeking stability, compliance, and long-term value.