In the global gua sha industry, material choice is no longer just a cosmetic preference. For wholesalers, distributors, and private-label brands, material directly affects cost control, durability, regulatory compliance, logistics efficiency, and long-term brand positioning. Among traditional stone, stainless steel, and resin tools, copper gua sha tools are increasingly gaining attention in professional massage, rehabilitation, and wellness markets.

Copper has been used in traditional therapy tools for centuries, but modern wholesale buyers now evaluate it through a commercial lens. They focus on sourcing stability, machining feasibility, surface treatment consistency, and international shipping performance. This article is written from the perspective of Deyi Gems, a manufacturer and wholesale supplier with long-term experience in gua sha production, OEM customization, and international logistics coordination.

This comprehensive guide focuses on one central concept—Copper Gua Sha Wholesale—and explains how cost structure, manufacturing processes, safety compliance, and logistics all interact when sourcing copper gua sha tools at scale.

Understanding Copper as a Gua Sha Material

The Physical Properties of Copper Relevant to Gua Sha Tools

Copper is a non-ferrous metal with high thermal conductivity, moderate density, and excellent machinability. These physical properties directly influence how copper performs as a gua sha tool. Compared with natural stone, copper transfers heat more efficiently, which is particularly valued in muscle recovery and professional massage settings.

From a production standpoint, copper has a density of approximately 8.96 g/cm³, which provides a solid hand feel without becoming excessively heavy. This balance allows copper gua sha tools to be used for longer sessions without causing user fatigue. According to material property data published by the International Copper Association, copper’s thermal conductivity is about 401 W/m·K, significantly higher than stainless steel and most stones, which explains its warming response during skin contact.

Authoritative reference:

International Copper Association – Material Properties

https://copperalliance.org

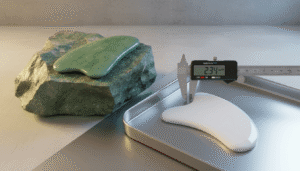

Copper vs Other Common Gua Sha Materials

In wholesale decision-making, copper is often compared with stainless steel and natural jade or quartz. Stone tools rely heavily on raw material grading and cutting yield, which introduces price volatility. Stainless steel offers consistency but lacks the traditional therapeutic perception associated with copper.

Copper occupies a middle position. It is more industrial than stone but carries a stronger traditional and therapeutic narrative than steel. This makes it especially suitable for brands targeting physical therapists, sports recovery clinics, and traditional therapy institutions.

From a branding perspective, copper allows for precise shape control and surface finishing, which is more difficult to achieve consistently with natural stone materials.

Copper Gua Sha Wholesale Cost Structure Explained

Raw Material Pricing and Market Volatility

Copper pricing is primarily driven by the global commodities market. Wholesale buyers should understand that copper prices fluctuate based on supply, demand, and geopolitical factors. According to data from the London Metal Exchange (LME), refined copper prices typically range between USD 7,500 and USD 9,500 per metric ton, depending on market conditions.

This volatility affects base material costs but is generally more predictable than gemstone pricing, which varies significantly based on mining output and grade availability. For wholesale buyers, copper’s standardized global pricing offers clearer cost forecasting.

Authoritative reference:

London Metal Exchange – Copper Market Data

https://www.lme.com

Manufacturing and Machining Costs

Unlike stone gua sha tools, copper tools are manufactured through CNC machining, casting, or forging, followed by polishing and surface treatment. This industrialized process ensures high dimensional consistency, which is critical for bulk wholesale orders.

Machining copper requires skilled operators and controlled cutting speeds due to copper’s softness and tendency to stick during processing. These technical requirements increase labor cost compared to steel but remain lower than the waste loss often associated with stone cutting.

In high-volume production, copper gua sha unit costs generally stabilize once tooling and process parameters are finalized. This stability is one of the main reasons copper is favored in long-term OEM projects.

Surface Treatment and Finishing Options for Copper Gua Sha Tools

Polishing Standards and Skin Contact Safety

Surface smoothness is a non-negotiable requirement for gua sha tools. Copper tools must undergo multi-stage polishing to remove micro-burrs and machining marks. In professional production, surface roughness is controlled below Ra 0.8 μm, ensuring safe and comfortable skin contact.

Poor polishing can result in oxidation spots or uneven skin sensation, which is unacceptable in professional markets. Reputable manufacturers follow standardized polishing protocols and conduct manual inspections before packaging.

Coating, Plating, and Oxidation Control

Copper naturally oxidizes when exposed to air and moisture. To address this, wholesale copper gua sha tools may undergo surface treatments such as clear coating, PVD plating, or controlled patina finishing.

Clear protective coatings are commonly used for export markets, as they maintain the original copper color while preventing oxidation during shipping and storage. From a compliance perspective, coatings must meet safety standards for skin contact.

For reference, the U.S. Food and Drug Administration (FDA) provides general guidance on materials intended for skin contact, emphasizing corrosion resistance and surface stability.

Authoritative reference:

FDA – Materials for Medical and Consumer Use

https://www.fda.gov/medical-devices

Quality Control Standards in Copper Gua Sha Wholesale

Dimensional Accuracy and Weight Consistency

In wholesale orders, consistency matters more than individual aesthetics. Copper gua sha tools are measured against strict dimensional tolerances, typically within ±0.2 mm, to ensure uniform user experience across batches.

Weight consistency is equally important. Professional buyers often specify a weight range to ensure ergonomic performance, especially for therapeutic applications.

Defect Inspection and Batch Testing

Each production batch undergoes visual inspection for surface defects, coating integrity, and edge smoothness. Random sampling is also used to test coating adhesion and oxidation resistance.

Compared with stone tools, copper offers a lower defect rate at scale, which reduces post-delivery complaints and return risks for wholesalers.

Copper Gua Sha Customization for Wholesale Buyers

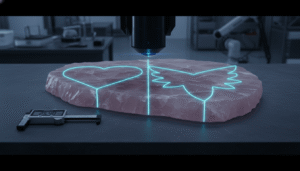

Shape Design and Functional Optimization

Copper allows greater design freedom than stone. Custom shapes for facial, body, or rehabilitation use can be developed with precision. This flexibility is particularly valuable for brands targeting niche professional markets.

From an OEM perspective, digital design files ensure repeatability, making copper ideal for long-term product lines.

Branding, Logo, and Private Label Options

Laser engraving and CNC engraving are commonly used for logo placement on copper gua sha tools. Unlike stone engraving, copper engraving offers sharper edges and better durability.

Private-label brands benefit from copper’s ability to support clean, modern branding without compromising structural integrity.

Regulatory and Compliance Considerations

Material Safety and Export Requirements

Copper gua sha tools must comply with consumer product safety regulations in destination markets. While copper itself is widely accepted, surface treatments and coatings must meet chemical safety standards such as REACH in the European Union and CPSIA guidelines in the United States.

Wholesale buyers should request compliance documentation from suppliers to ensure smooth customs clearance.

Authoritative reference:

European Chemicals Agency – REACH Regulation

https://echa.europa.eu

Documentation for International Trade

Proper HS codes, material declarations, and packing lists are essential for copper gua sha exports. Copper tools are generally classified under metal massage or therapeutic instruments, depending on local customs definitions.

Experienced suppliers assist wholesalers by preparing accurate documentation, reducing clearance delays.

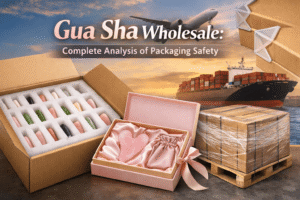

Logistics and Shipping Advantages of Copper Gua Sha Tools

Packaging Efficiency and Damage Reduction

Copper tools are less fragile than stone, which significantly reduces breakage during transit. This allows for more compact packaging and higher carton utilization rates.

For sea freight and air freight alike, copper’s durability translates into lower insurance claims and fewer damaged goods upon arrival.

Shipping Cost and Weight Considerations

Although copper is heavier than stone on a per-unit basis, the reduction in breakage risk often offsets higher freight costs. Additionally, uniform shapes allow optimized packing density, improving cost efficiency per unit shipped.

Wholesale buyers often find that copper gua sha tools deliver more predictable landed costs compared to fragile stone alternatives.

Market Positioning and Buyer Profiles for Copper Gua Sha Wholesale

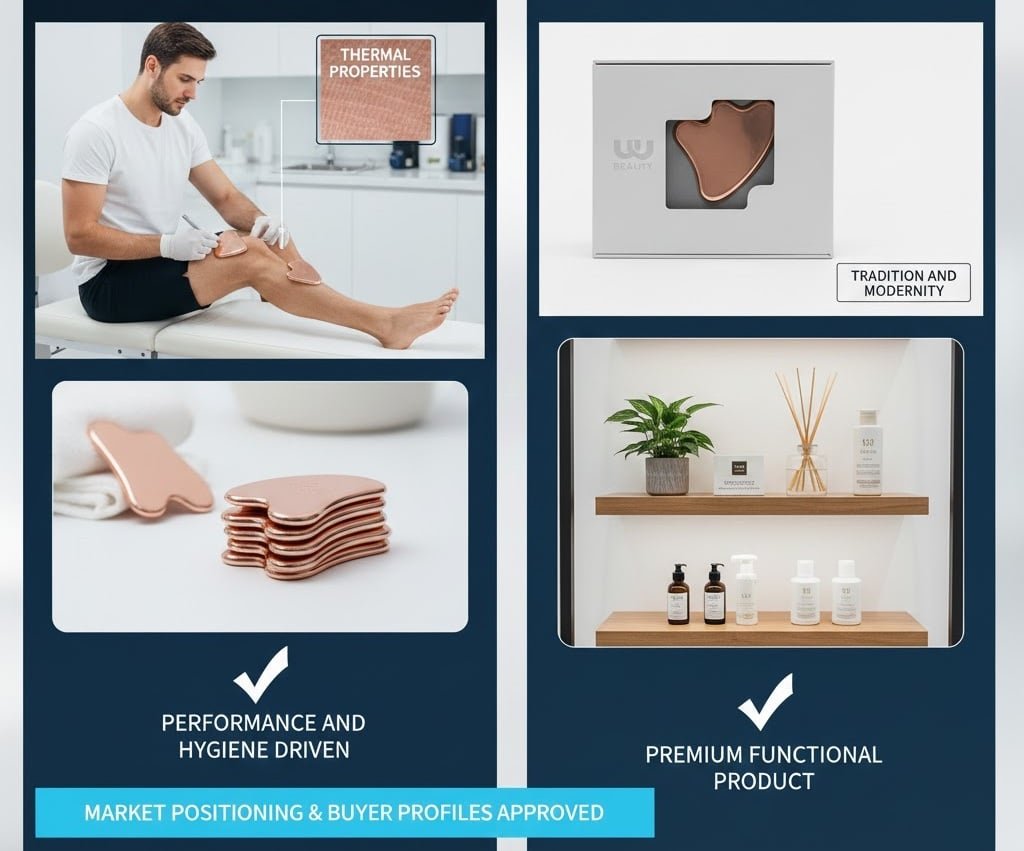

Professional Therapy and Sports Recovery Markets

Copper gua sha tools are widely accepted in physical therapy, sports recovery, and rehabilitation settings. Their durability and thermal properties align well with professional usage patterns.

These markets prioritize performance and hygiene over decorative appearance, making copper a logical choice.

Retail and Wellness Brand Opportunities

For wellness brands, copper offers a compelling blend of tradition and modernity. With proper surface finishing and branding, copper gua sha tools can be positioned as premium functional products rather than decorative accessories.

Conclusion: Is Copper Gua Sha Wholesale Right for Your Business?

Copper gua sha wholesale is not simply a material choice; it is a strategic sourcing decision. From cost predictability and manufacturing consistency to logistics efficiency and regulatory compliance, copper offers clear advantages for professional and large-scale buyers.

At Deyi Gems, our experience in copper gua sha production and global wholesale logistics has shown that copper is especially well-suited for long-term OEM projects and professional markets. For wholesalers seeking durability, consistency, and scalable customization, copper gua sha tools represent a reliable and future-oriented option.

As the global gua sha market continues to evolve, copper is positioned not as a trend material, but as a stable foundation for professional gua sha product lines.