In the global wellness and beauty market, gua sha tools are often discussed from a consumer or brand perspective. Online conversations typically focus on shapes, materials, facial techniques, or short-term trends. However, these discussions rarely explain how gua sha tools are actually produced, evaluated, and stabilized at scale.

From the viewpoint of a gua sha manufacturer, the industry looks fundamentally different. Manufacturing is not only about producing attractive tools, but about managing raw material variability, machining tolerances, surface safety, regulatory reference frameworks, defect control, and long-term supply consistency. These factors determine whether a product can be reliably produced and supplied—not just whether it looks appealing in a sample.

As a long-established manufacturer and wholesale supplier under the Deyi Gems brand, our experience spans raw material sourcing, OEM and ODM development, quality control, and international B2B distribution. This article explains how manufacturers evaluate gua sha products, and why this perspective often differs from that of buyers.

- Understanding the Role of a Gua Sha Manufacturer

- Raw Materials: How Manufacturers Evaluate Them Differently

- Design and Shape: Production Reality vs Market Expectations

- Quality Control: What Happens Before Final Inspection

- Pricing Logic: Factory Cost Structure vs Buyer Expectations

- OEM and ODM: Factory Responsibilities Explained

- Regulatory Reference Frameworks and Market Access

- Logistics and Supply Chain Considerations

- How Buyers and Manufacturers Can Align More Effectively

- Data Scope and Regulatory Reference Disclaimer

- Conclusion: The Value of the Manufacturer’s Perspective

Understanding the Role of a Gua Sha Manufacturer

Manufacturing Is a System, Not a Single Step

A professional gua sha manufacturer operates across multiple interconnected stages. These include upstream raw material selection, midstream shaping and finishing, and downstream inspection, packaging, and logistics preparation. Each stage influences product safety, durability, and cost.

Unlike traders or resellers, factories must absorb losses caused by material defects, processing errors, and transit damage. These operational realities strongly influence how manufacturers assess designs, materials, and order structures.

Manufacturer Responsibility vs Buyer Flexibility

Buyers often evaluate products by price, appearance, and branding potential. Manufacturers, by contrast, are responsible for consistency across hundreds or thousands of units. When quality fluctuates, factories cannot simply replace inventory without cost.

This difference explains why manufacturers tend to be conservative about certain design requests. A visually appealing concept may carry hidden risks that only become visible during mass production or international shipping.

Raw Materials: How Manufacturers Evaluate Them Differently

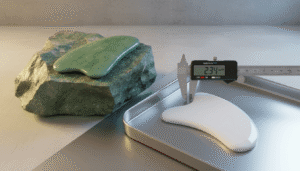

Natural Stone Beyond Visual Appearance

For many buyers, the primary indicators of stone quality are color, translucency, or surface polish. From a manufacturer’s standpoint, internal structure and mechanical stability are more critical.

Natural stones such as nephrite jade, rose quartz, obsidian, and amethyst vary in hardness, grain structure, and internal inclusions. For reference, nephrite jade typically measures around Mohs 6.0–6.5, while rose quartz averages Mohs 7.0, a difference that directly affects cutting speed, tool wear, and edge stability during mass production. According to the Gemological Institute of America (GIA), inclusions and microfractures influence how gemstones behave during cutting and polishing, directly affecting durability and yield rates.

Source: Gemological Institute of America (GIA) – Gem Materials & Durability

https://www.gia.edu

Manufacturers routinely reject a portion of raw stone before processing begins. This pre-production loss is rarely visible to buyers, yet it is a real cost factor embedded in pricing.

Metal and Alternative Materials Require Framework Alignment

With the growing popularity of stainless steel, copper, and alloy gua sha tools, manufacturers must evaluate materials against recognized safety and material performance frameworks.

For example, stainless steel commonly used for wellness tools is selected for corrosion resistance and cleanability. In the United States, material characteristics relevant to skin-contact applications are referenced in guidance published by the U.S. Food and Drug Administration (FDA). It is important to clarify that such references apply to material properties rather than certifying gua sha tools as medical devices.

Source: U.S. FDA – Medical Device Materials Overview

https://www.fda.gov/medical-devices

From a factory perspective, surface finishing processes must also be controlled to avoid burrs, sharp edges, or residues that could affect skin comfort.

Design and Shape: Production Reality vs Market Expectations

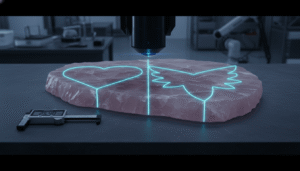

Shape Complexity and Manufacturing Consistency

Unique shapes are often requested to support brand differentiation. Manufacturers evaluate these requests by assessing machining feasibility and repeatability.

Complex curves, concave edges, or asymmetrical designs require precise tooling and skilled labor. In stone tool production, dimensional tolerances are commonly controlled within ±0.5–1.0 mm for functional edges, as deviations beyond this range can be perceptible during skin contact. Even small deviations in curvature or thickness can affect user comfort. Maintaining these tolerances across large batches increases production time and inspection requirements.

Manufacturers therefore assess not only whether a design is attractive, but whether it can be produced consistently without excessive defect risk.

Thickness as a Structural Consideration

Thickness is often discussed by buyers in terms of weight or elegance. In manufacturing, thickness is a structural variable linked to breakage risk.

Based on long-term production observations, reducing stone thickness beyond certain thresholds tends to increase the likelihood of cracking during polishing and transportation. For many common gua sha stones, manufacturers often set a practical minimum thickness of approximately 4–6 mm for facial tools to balance ergonomics and structural safety, although exact limits vary by material and design. Exact percentages vary depending on material type and process conditions, but the relationship between reduced thickness and higher defect risk is a well-recognized consideration in stone-based manufacturing.

This is why factories often recommend minimum thickness standards even when thinner designs appear visually appealing.

Quality Control: What Happens Before Final Inspection

Multi-Stage Quality Control Processes

Buyers typically associate quality control with final visual inspection. In manufacturing, quality control begins much earlier.

Raw materials are sorted, semi-finished pieces are checked for stress lines, and polished tools are evaluated for edge smoothness and dimensional stability. Batch sampling is used to monitor weight consistency and shape tolerances.

Factories that follow structured quality management systems aim to reduce variability rather than correct defects after they occur. In practice, batch sampling ratios of 3–5% are commonly used during mid-process inspection to monitor weight, thickness, and surface consistency. This approach aligns with principles outlined in ISO 9001 quality management frameworks.

Source: International Organization for Standardization (ISO) – ISO 9001 Overview

https://www.iso.org/iso-9001-quality-management.html

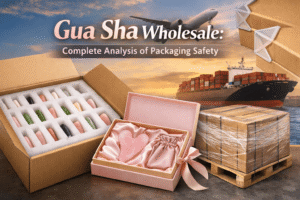

Packaging as a Quality Factor

From a manufacturer’s perspective, packaging is part of product safety. Stone tools require cushioning, spacing control, and protection against vibration.

Factories evaluate packaging performance by monitoring shipping damage patterns. Repeated damage feedback often leads to packaging or design adjustments in future batches.

Pricing Logic: Factory Cost Structure vs Buyer Expectations

Beyond Material and Labor Costs

Buyers sometimes estimate cost based on visible factors such as material weight and labor time. Manufacturers must also account for tooling wear, machine depreciation, energy consumption, and defect loss.

For example, polishing stone tools requires abrasive tools that degrade over time. In continuous production, diamond or silicon-carbide abrasives may require replacement after several hundred units, depending on stone hardness and surface finish requirements. Replacing these tools improves surface quality but increases operating costs. Factories balance these factors to achieve stable output rather than minimum short-term pricing.

Stability Over Short-Term Discounts

From a manufacturing standpoint, stable order volumes allow better production planning and lower defect rates. This often results in more consistent quality over time.

Short-term price pressure may reduce unit cost temporarily but can introduce variability. Experienced manufacturers prioritize sustainable pricing structures that support repeatability and long-term cooperation.

OEM and ODM: Factory Responsibilities Explained

OEM Execution Accuracy

In OEM projects, buyers provide designs and branding elements. Manufacturers focus on execution accuracy, including logo placement, engraving depth, and surface integrity.

Factories also evaluate whether branding elements introduce structural stress points, particularly in stone tools. Adjustments are sometimes recommended to balance aesthetics and durability.

ODM and Design Accountability

In ODM development, manufacturers assume responsibility for both design and production feasibility. Market trends are considered alongside manufacturability and quality stability.

Designs that cannot be reliably produced at scale are typically revised or rejected. This process is informed by internal testing, defect analysis, and long-term production feedback.

Regulatory Reference Frameworks and Market Access

Understanding the Scope of Compliance References

Manufacturers supplying international markets must consider chemical and material frameworks such as the EU REACH regulation, which governs the use of certain substances.

The European Chemicals Agency (ECHA) publishes guidance on restricted substances and material safety considerations. These frameworks inform material selection but do not constitute product certification unless explicitly stated.

Source: European Chemicals Agency (ECHA) – REACH Regulation Overview

https://echa.europa.eu/regulations/reach

Clear understanding of regulatory scope helps prevent misinterpretation by buyers and end markets.

Logistics and Supply Chain Considerations

Shipping Feedback as Manufacturing Data

Manufacturers track shipping damage rates as part of quality analysis. In factory records, acceptable transit damage rates are often targeted below 1–2% per shipment, with higher figures triggering packaging or design reassessment. High damage incidence often indicates design or packaging vulnerabilities.

This feedback loop supports continuous improvement and helps reduce future losses.

Raw Material Availability and Planning

Natural stone availability can fluctuate due to mining conditions and export policies. Manufacturers manage inventory planning to balance supply stability with production schedules.

Urgent large-volume requests may face limitations that are not immediately visible to buyers.

How Buyers and Manufacturers Can Align More Effectively

Communication Improves Outcomes

Clear communication about target markets, usage scenarios, and quality expectations enables manufacturers to recommend appropriate materials and designs.

This reduces redesign cycles, sampling costs, and misunderstandings.

Experience as a Reliability Indicator

From a factory perspective, long-term experience contributes to process stability and quality consistency. Manufacturers with established production histories tend to manage variability more effectively.

Evaluating factories based on technical understanding rather than surface appearance supports stronger partnerships.

Data Scope and Regulatory Reference Disclaimer

The manufacturing insights presented in this article are based on long-term production experience within the gua sha industry. Observations related to defect risk, breakage tendencies, and process stability reflect internal manufacturing patterns rather than publicly audited datasets.

References to organizations such as GIA, ISO, FDA, and ECHA are provided to explain relevant material science principles and regulatory frameworks. These references do not imply product certification unless explicitly stated.

Conclusion: The Value of the Manufacturer’s Perspective

The gua sha industry is often viewed through a consumer-facing lens, yet product quality and reliability begin at the manufacturing level. A gua sha manufacturer must balance material science, process control, compliance awareness, and logistics to deliver consistent tools at scale.

When buyers understand these manufacturing realities, sourcing decisions become more informed and partnerships more sustainable. From the factory perspective, this alignment is essential for producing gua sha tools that perform reliably beyond first impressions.