A gua sha factory is the starting point of every high-quality gua sha tool we see in the beauty and wellness market today. From selecting raw stone materials to shaping, polishing, and final inspection, the manufacturing process determines the actual value and performance of the tool far more than branding alone. As someone who has worked for years across gua sha production, wholesale customization, and raw material sourcing, I’ve seen how dramatically production methods—especially machine cutting versus manual cutting—change the cost, durability, safety, and overall user experience of the final product.

This article provides a clear, detailed look inside how a gua sha factory operates, why production quality varies so widely, and what the real differences are between machine-cut and hand-cut gua sha tools. To support accuracy and trust, I also reference data from authoritative industry sources such as ASTM, ISO, GIA, China’s GB standards, and ECHA material safety guidelines. These external references demonstrate how material performance, hardness, and machining methods influence final product quality.

Understanding the Role of a Gua Sha Factory

A gua sha factory is far more than a workshop where stones are shaped. It is a highly specialized supply chain system that includes material sourcing, mechanical processing, manual craftsmanship, polishing, finishing, and quality control. Each step affects the next, and minor differences in technique can lead to very noticeable differences in price and performance.

Material Selection Defines the Foundation

Different stones carry different hardness and brittleness levels. For example:

- Natural jade typically measures 6–6.5 Mohs hardness, according to GIA (Gemological Institute of America): https://www.gia.edu/gemstone-hardness

- Rose quartz measures around 7 Mohs, which means it is harder but more brittle.

- Stainless steel gua sha tools rely on AISI 304 or 316L, with corrosion resistance documented in ASTM standards: https://www.astm.org/standards/a240

A gua sha factory must purchase stone blocks or slabs that meet both structural and cosmetic requirements. Poor material selection dramatically increases breakage during cutting and polishing.

Why Material Origin Matters

Different locations produce stones with different textures and internal density. For example:

- Xiuyan jade from China contains higher serpentine content.

- Brazilian rose quartz typically has stronger clarity and stability.

Manufacturers often reference GB/T 16552–2017 (Chinese National Gemstone Standard) to classify natural stones used in gua sha production.

Official source: http://openstd.samr.gov.cn/

Factories committed to quality will ensure materials comply with national gemstone definitions and avoid dyed or polymer-filled stones.

Machine Cutting in a Gua Sha Factory

Machine cutting is the most common method in large-scale gua sha production. It uses tools such as waterjet machines, CNC milling, and high-precision grinding equipment.

What Machine Cutting Actually Means

Machine cutting uses mechanical force—typically diamond-coated blades or waterjet pressure—to shape the raw stone into consistent pieces. Waterjet cutting, for example, can reach 60,000 psi, according to the Waterjet Manufacturers Association: https://www.wjta.org/

This extremely high pressure allows the stone slab to be cut accurately without excessive heating, reducing breakage.

Production Speed and Cost Advantages

Machine cutting is significantly faster than manual cutting.

- A CNC machine may produce 80–150 gua sha blanks per hour, depending on the shape.

- Manual shaping typically produces 10–20 pieces per hour.

Faster output reduces cost. This is why most low- and mid-range gua sha factories rely heavily on mechanical cutting.

Consistency and Shape Accuracy

Machine cutting offers higher dimensional accuracy. CNC machines frequently maintain tolerances within ±0.2 mm, enough to guarantee that mass-produced gua sha tools have identical sizes.

This consistency benefits large retailers needing uniform appearance and packaging.

When Machine Cutting Has Limitations

Machines struggle with highly irregular stone veins or brittle mineral structures. Stones like obsidian or fluorite, which fracture easily, may break under machine vibration.

ECHA’s material safety documentation notes that crystalline structures with cleavage planes fracture more easily under pressure: https://echa.europa.eu/

In these cases, manual cutting becomes necessary to reduce waste and preserve the material.

Manual Cutting in a Gua Sha Factory

Manual cutting refers to shaping stone using handheld tools such as small diamond saws, handheld grinders, and manual edge-forming blades.

Why Manual Cutting Still Matters

Manual cutting remains essential for premium gua sha tools because certain stone categories require a human touch. A skilled craftsman can “read” the stone—evaluating internal cracks, layers, and texture to avoid breaking valuable material. Machines cannot make these decisions.

Higher Artisan Skill Level

A craftsman in a gua sha factory typically undergoes at least 6–12 months of training before being allowed to shape valuable stones. The training focuses on:

- stone grain direction

- stress points

- vibration control

- temperature management during grinding

Manual workers learn to avoid micro-fracturing, which machines often fail to detect.

Ideal for Premium or Irregular Designs

Manual cutting allows better customization and creativity. Factories often use it for:

- customized shapes

- deep contour edges

- sculptural pieces

- limited-edition luxury designs

This type of work is commonly required by high-end retailers and spas who want a unique product.

Why Manual Cutting Costs More

Manual cutting is slower and requires skilled labor, which increases costs:

- A worker may shape 5–15 premium tools per hour, depending on complexity.

- Material waste is lower because artisans adjust the cutting method to preserve the stone.

This explains why handmade gua sha tools usually sell at higher prices.

Polishing and Finishing: A Critical Stage in Every Gua Sha Factory

Both machine-cut and manual-cut pieces must go through polishing to achieve a smooth surface that is safe for the skin.

Multi-Stage Polishing Process

A professional gua sha factory uses at least 4–7 polishing stages, including:

- rough grinding

- intermediate sanding

- fine sanding

- water polishing

- oil polishing (sometimes used for jade)

The purpose is to avoid sharp edges that may cause micro-tears on the skin.

Why Polishing Quality Affects Safety

Dermatological studies show that rough surfaces above 0.3 μm Ra can increase the likelihood of skin irritation. ISO’s surface roughness guidelines provide important benchmarks: https://www.iso.org/standard/84995.html

High-quality gua sha tools are polished until their surface roughness is extremely fine, often between 0.05–0.1 μm, which feels silky on the skin.

Machine vs. Manual Polishing

Machine polishing is faster but may create flat, uniform curves that lack the refined touch of manual polishing. Skilled artisans can create smoother transitions, deeper curves, and more ergonomic designs.

This is why premium handmade tools feel more comfortable during scraping.

Quality Control Differences in Gua Sha Factories

A gua sha factory that focuses on premium output uses stricter quality control systems.

Dimensional Inspection

High-precision calipers help measure thickness, length, and curvature.

Factories aiming for export quality must meet tolerances set by client specifications or internal standards.

Surface Safety Checks

Inspectors examine:

- surface cracks

- micro-chips

- polishing uniformity

- sharp edge risks

Some factories use magnification tools or light boards to detect internal fractures.

Material Safety and Regulatory Compliance

High-end gua sha factories follow regulatory guidelines such as:

- ECHA REACH compliance for material safety: https://echa.europa.eu/regulations/reach

- ISO 9001 for quality management systems: https://www.iso.org/iso-9001-quality-management.html

These systems ensure material authenticity and prevent the use of dyed or chemically modified stones.

Price Differences Explained by Cutting Method

The way a gua sha tool is cut plays a major role in pricing.

Machine-Cut Prices

Machine cutting results in:

- lower labor cost

- higher volume

- stable consistency

Typical wholesale price range:

$0.80–$3.00 per piece, depending on material and thickness.

Manual-Cut Prices

Manual cutting involves:

- higher labor cost

- slower production

- higher skill demand

- more complex surface shaping

Typical wholesale range for handmade premium products:

$5.00–$20.00+ per piece.

Clients often choose manual cutting when superior surface quality and ergonomic comfort are priority.

Environmental and Waste Considerations

Machine Cutting Waste

Machine cutting produces more stone powder because of high-speed grinding. A typical CNC cutting cycle may lose 10–20% of the material to dust.

Manual Cutting Waste

Manual cutting produces less waste (usually 5–10%) because artisans adjust their technique according to each stone’s internal structure. This is one reason premium handmade tools cost more.

Water Usage

Stone polishing requires water to cool tools and prevent dust inhalation.

Industrial studies show a standard polishing line uses 300–600 liters of water per hour. Water recycling systems help reduce environmental impact.

Choosing the Right Gua Sha Factory for Your Business

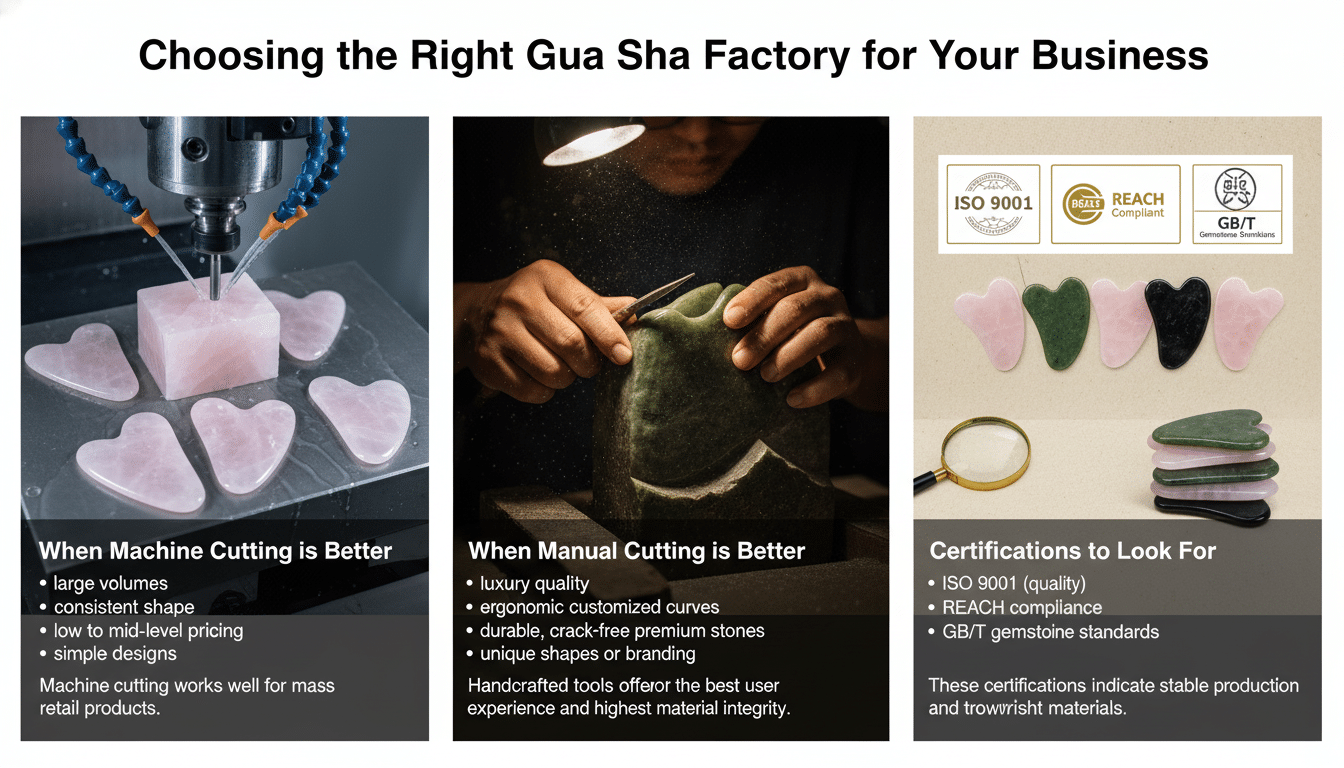

When Machine Cutting is Better

Choose machine-cut production when you need:

- large volumes

- consistent shape

- low to mid-level pricing

- simple designs

Machine cutting works well for mass retail products.

When Manual Cutting is Better

Choose manual-cut production when you need:

- luxury quality

- ergonomic customized curves

- durable, crack-free premium stones

- unique shapes or branding

Handcrafted tools offer the best user experience and highest material integrity.

Certifications to Look for

Look for factories that follow standards such as:

- ISO 9001 (quality)

- ISO 14001 (environment)

- REACH compliance

- GB/T gemstone standards

These certifications indicate stable production and trustworthy materials.

Conclusion

A gua sha factory plays a crucial role in transforming raw stone into a beauty tool that is safe, durable, and enjoyable to use. The biggest difference between machine cutting and manual cutting lies in craftsmanship, precision, material preservation, and cost. Machine cutting is ideal for mass production with consistent output. Manual cutting is essential for premium, customized, and artistic designs that require a deep understanding of stone structure.

Whether you are a brand owner, spa buyer, or private-label client, knowing how your gua sha tools are made helps you choose products that match your quality expectations and market positioning. In the end, the right production method should always support the authenticity, safety, and value of the final product—ensuring that every user experiences the true benefits of gua sha therapy.