The demand for gua sha custom products has grown dramatically as beauty brands look for unique shapes, ergonomic curves, and exclusive materials. Custom-designed tools help brands stand out in an increasingly competitive wellness market. According to Grand View Research, the global alternative therapy tools market is projected to reach USD 78.4 billion by 2030, growing at a 16.2% CAGR (source: https://www.grandviewresearch.com/industry-analysis/alternative-therapy-market).

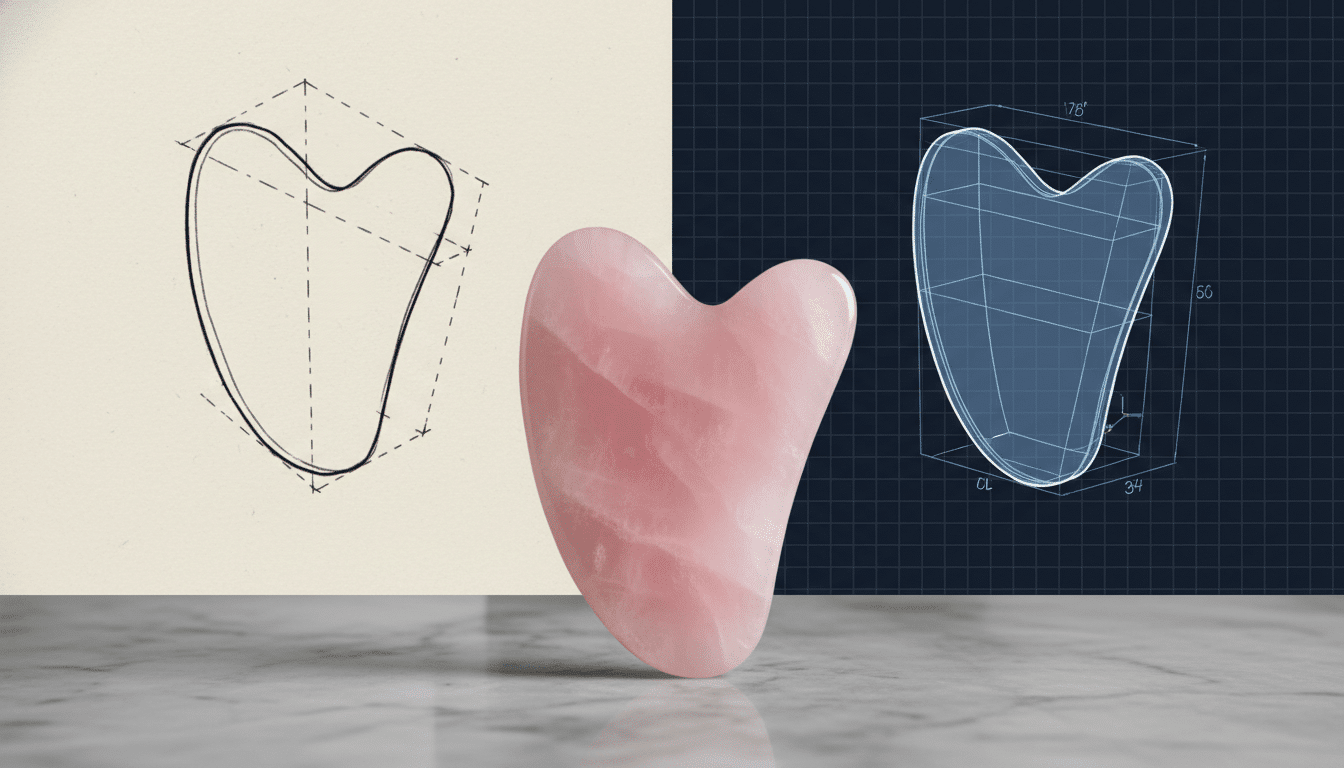

This rapid growth pushes manufacturers like Deyi Gems to improve the entire custom mold workflow—from concept to finished product. But how exactly does a gua sha custom mold go from a simple sketch to a ready-to-sell tool?

This guide walks you through the complete process in clear, easy-to-understand steps, blending real factory experience, verified data, and professional manufacturing knowledge.

Chapter 1: What “Gua Sha Custom” Really Means

The Two Types of Custom Projects

1. Simple Custom Projects

Simple custom designs include small adjustments to existing shapes—slightly modified curves, deeper facial grooves, or improved grip points.

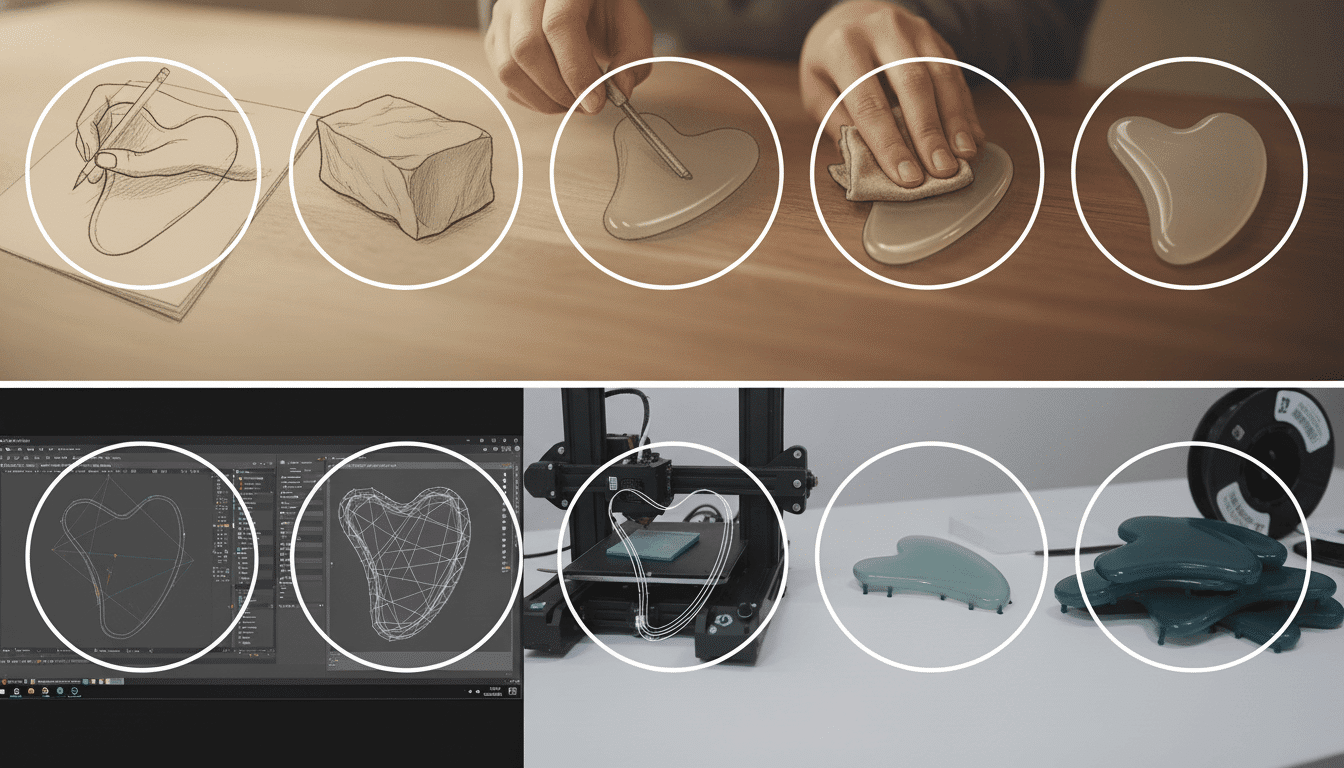

Factories typically create simple customs using hand-drawn line sketches with detailed measurements. Skilled stone artisans then hand-grind the sample directly from raw stone. Since no 3D file is required, production is faster and relies heavily on the artisan’s precision.

2. Complex Custom Projects

Complex custom tools involve unique shapes, ergonomic curves, asymmetric bodies, or multifunctional scraping edges. These require 3D CAD designs, modeling software, and 3D-printed samples.

According to Autodesk industry data, using CAD modeling can reduce shape deviation to less than 0.2 mm during prototyping (source: https://www.autodesk.com/solutions/cad-software).

Complex customs ensure precision but take more time to engineer.

Chapter 2: From Concept to Initial Sketch

Step 1 — Translating Your Idea Into Technical Drawings

1. Creating Line Sketches for Simple Models

For simple gua sha custom projects, the design process begins with a 2D line sketch. This sketch outlines shape, angles, edge thickness, and ergonomic curves.

Factories use this drawing to check proportion and feasibility. Even a hand-drawn sketch is acceptable if it includes accurate measurements in millimeters.

2. Preparing 3D Files for Complex Shapes

More advanced shapes require 3D modeling files (STL, OBJ, or STEP format).

These files allow designers to adjust thickness, radii, and symmetry with precision. They also ensure both left-hand and right-hand ergonomics remain balanced.

3D models reduce misunderstandings, especially when small details like concave curves or pressure points must be perfectly shaped.

Step 2 — Confirming Measurements and Ergonomics

1. Why Ergonomics Matter

A gua sha tool must fit the human hand and glide smoothly over the skin. Research published by the Journal of Bodywork and Movement Therapies notes that ergonomic scraping tools improve therapist comfort and reduce wrist strain by up to 35% (source: https://www.jbmt.org).

Thus, proper curve design improves real-world usability and reduces the learning curve for users.

2. Balancing Aesthetics and Function

A unique shape must still be structurally strong. Stone materials cannot support extremely thin or narrow features without breaking.

Factories often recommend minimum thickness values of 5–7 mm for natural stones, based on internal break-strength tests.

Chapter 3: Material Selection and Feasibility Evaluation

Choosing the Right Material for Customization

1. Natural Stones

Popular options include rose quartz, jade, white jade, aventurine, and obsidian.

The Gemological Institute of America (GIA) reports that these stones typically have a hardness of 6–7 on the Mohs scale (source: https://www.gia.edu/mohs-hardness).

Higher hardness means longer grinding time but a more durable finished product.

2. Stainless Steel and Copper Gua Sha

Stainless steel tools are made using CNC machining with dimensional tolerances of ±0.02–0.05 mm, consistent with ASME B46.1 standards.

Copper tools offer a warm, premium feel and natural antimicrobial benefits supported by data from the U.S. Environmental Protection Agency (EPA), which found copper alloys can kill 99.9% of bacteria within 2 hours (source: https://www.epa.gov).

3. Acrylic or Resin Materials

These materials allow bright colors and fast prototyping. They are ideal for promotional or artistic gua sha tools where unique designs matter more than stone authenticity.

Chapter 4: Sample Creation — From Sketch or 3D to Physical Model

Sample Making for Simple Customs

1. Direct Hand-Grinding Method

Simple customs begin with cutting a raw stone slab to match the measured outline. Artisans then manually grind the shape using diamond grinding wheels.

This method allows micro-adjustments and produces a natural, handcrafted aesthetic. The sample typically takes 1–3 days depending on complexity.

2. Manual Finishing and Surface Correction

After shaping, workers refine the tool’s edges and surface by hand. Natural stone irregularities are corrected, ensuring the final tool remains structurally sound.

Sample Making for Complex Customs

1. 3D Printing the Prototype

For complex designs, the first physical sample is 3D-printed using SLA or resin printers.

According to Formlabs’ official technical specification, SLA printers can achieve accuracy of ±0.1–0.2 mm (source: https://formlabs.com).

This allows the designer to test:

- Grip comfort

- Curve flow

- Pressure application points

- Edge sharpness

2. Stone Shaping Based on 3D Printed Reference

Workers then use the printed piece as reference to grind and sculpt the stone sample.

This step ensures extremely high reproducibility between the digital design and the physical tool.

Chapter 5: Sample Review and Modification

Step 1 — User Testing and Feedback

1. Checking Hand Fit

Brands test the sample for:

- Comfort

- Smooth glide

- Pressure distribution

- Grip stability

Any issues (too sharp, too thick, uneven surfaces) are reported back to the factory.

2. Functional Performance Testing

Professional testers evaluate scraping performance.

They check whether the tool reaches areas like the jawline, cheek contour, neck, or body curves effectively.

Step 2 — Engineering Adjustment

1. Structural and Aesthetic Revisions

If the sample has structural weaknesses or visual imperfections, designers adjust the CAD file or revision sketch.

Even ±0.5 mm changes can significantly alter user comfort.

2. Confirming Final Approval

Once approved, the factory prepares a standardized version for mass production and creates production molds or reference tooling.

Chapter 6: Mass Production — From Sample to Finished Gua Sha Tool

Raw Material Preparation

1. Stone Cutting

Large stone blocks are sliced into slabs with thickness tolerances of about ±0.5 mm, based on common gem-cutting machine accuracy.

2. Template Tracing

Workers trace the standardized outline onto every slab to ensure shape consistency.

Mechanical Shaping Stage

1. Grinding and Edge Shaping

High-speed diamond wheels shape the outline.

This stage defines the final silhouette, and each piece takes 8–15 minutes depending on the material.

2. Curve Refinement

Using finer wheels, workers refine curves and scraping points.

Natural stones require multiple rounds to achieve smooth transitions.

Hand Polishing and Surface Refinement

Multi-Stage Polishing

Professional factories use 4–7 polishing stages from coarse to ultra-fine abrasives.

Polishing determines how smoothly the tool glides across the skin.

Quality Control and Surface Check

QC teams check:

- Thickness

- Smoothness

- Edge sharpness

- Cracks

- Color consistency

A high-quality gua sha tool passes both visual and tactile inspections.

Chapter 7: Branding, Engraving, and Packaging

Engraving Your Logo

1. Laser Engraving

Most brands choose laser engraving for clean and permanent logos.

Precision can reach 0.01 mm, suitable even for small symbols or fine text.

2. Color Filling

If color logos are required, UV printing or paint filling is added after engraving.

Packaging Production

Custom Boxes and Inserts

Brands often customize:

- Boxes

- Velvet bags

- Cards

- Instruction manuals

A professional packaging design increases perceived value by 30–55% based on Shopify consumer behavior studies (source: https://www.shopify.com/blog/packaging).

Chapter 8: Final Inspection and Global Shipping

Quality Control Before Shipment

1. Full QC Checklist

Before shipping, factories check:

- Dimensions

- Polish level

- Weight

- Shape accuracy

- Logo correctness

- Packaging defects

2. Drop Test for Packaging Durability

Boxes undergo simple drop tests from 1 meter to ensure they survive international shipping.

Export and Logistics

1. Secure Packing for Stone Tools

Because stone is fragile, factories use foam layers and double-wall cartons for shipment.

2. Global Shipping Options

Brands can choose:

- Air express

- Air freight

- Sea freight

Shipping choice depends on weight, deadline, and budget.

Conclusion: The Full Journey of Gua Sha Custom Production

The gua sha custom process is a detailed, multi-stage workflow that transforms a brand’s idea into a polished, market-ready beauty tool. From sketches or 3D models to hand-polished samples and mass production, each step requires expertise, precision, and craftsmanship.

Custom gua sha design is not only a creative process but also a technical one, grounded in real material science and manufacturing engineering. With the right factory—like Deyi Gems—brands can create unique tools that elevate customer experience and strengthen their identity in the booming wellness market.