“Gua sha quality” has quickly become a key purchasing standard for brands, wholesalers, and consumers in the global beauty and wellness industry. As facial gua sha, body scraping tools, and crystal rollers continue to gain global popularity, the market is also experiencing massive differences in quality levels. On one end, there are high-end, properly polished, mineral-verified tools made from real stone or premium stainless steel. On the other end, there are low-cost, mass-produced pieces with inconsistent color, cracks, dull edges, and poor finishing.

Because the gua sha sector has no unified global grading system, the responsibility of defining what “high-quality” means falls directly on the factory. This is why factories with real craftsmanship — like Deyi Gems, a direct manufacturer with a decade of production experience — must be transparent about how grading works, what standards are used, and how every piece is evaluated before shipping.

This guide provides a complete breakdown of gua sha quality grading and evaluation standards, based fully on real manufacturing practice. It explains the differences between stone/crystal and metal gua sha tools, the exact criteria used to define A, B+, B, and C grades, the typical defects found in production, and why these details impact performance, safety, and durability.

To strengthen the article’s credibility, this guide also includes authoritative external references from mineral research institutions, material-science organizations, and cosmetic-tool safety regulators, including the Gemological Institute of America (GIA), ASM International, and the European Chemicals Agency (ECHA).

Chapter 1 – The Core Concept of Gua Sha Quality

Why “Gua Sha Quality” Has No Industry-Wide Standard

Unlike medical devices, gemstones, or metals, gua sha tools are not regulated under any internationally unified grading system. Bodies like ISO, ASTM International, or EN Standards do not publish gua sha-specific quality guidelines. Most material-specific data only covers things like mineral hardness, chemical composition, or stainless-steel corrosion resistance — not the finished gua sha product.

For instance:

- GIA provides mineral identification standards based on color, clarity, crystal structure, and inclusions, but does not grade gua sha tools specifically: https://www.gia.edu/gem-identification

- ASM International offers stainless steel composition and corrosion-resistance data but not cosmetic tool grading: https://www.asminternational.org

- ECHA regulates chemical safety of consumer products but does not inspect crystal or metal gua sha tools: https://echa.europa.eu/

Because there is no official grading system, factories define their own standards.

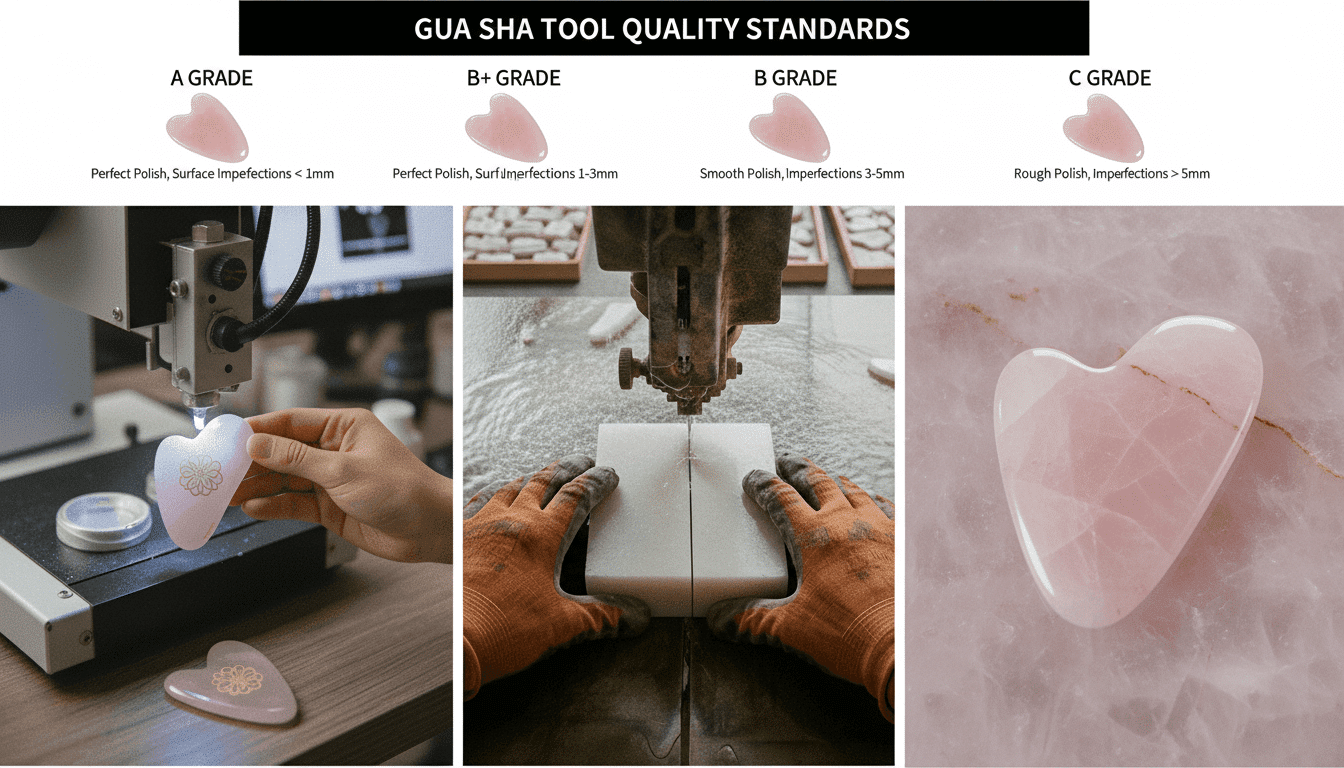

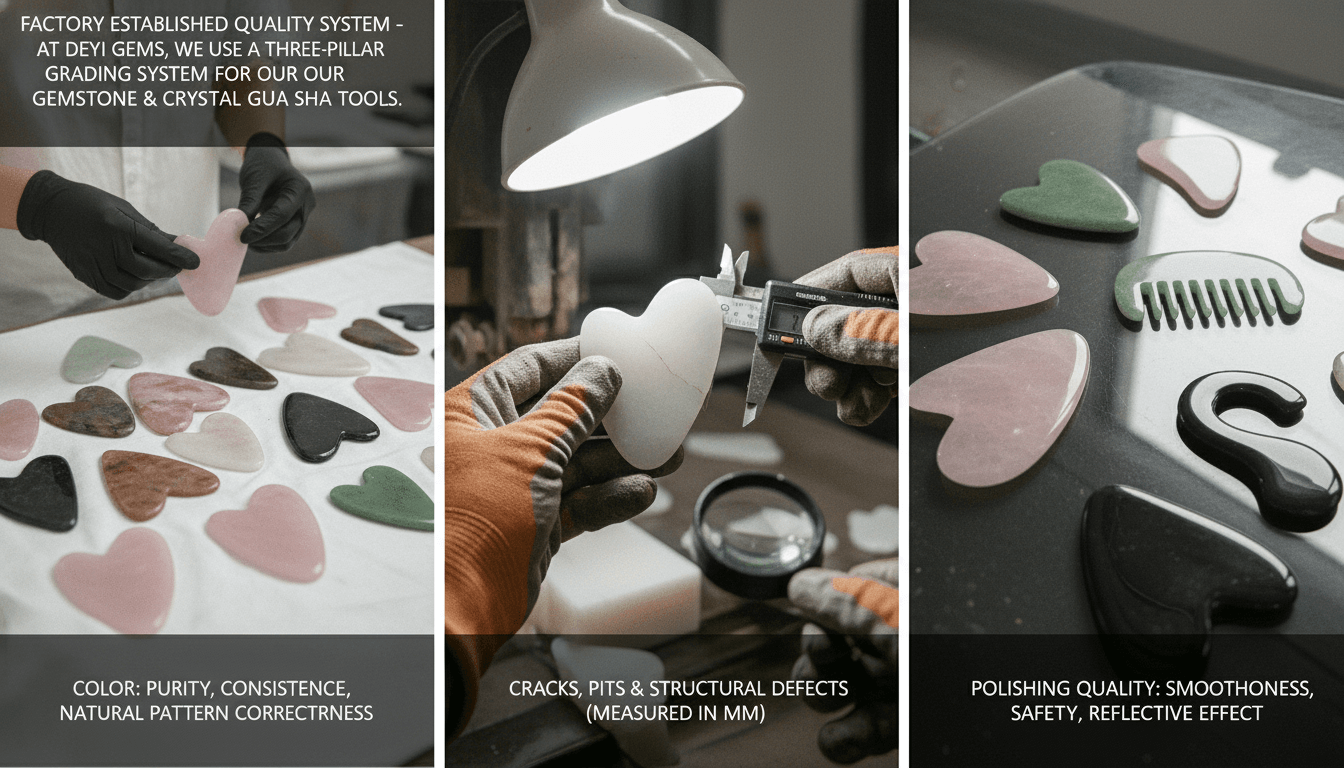

Factory-Established Quality Systems

At Deyi Gems, we rely on a three-pillar grading system for stone and crystal gua sha tools:

- Color (Purity, Consistency, Natural Pattern Correctness)

- Cracks, Pits & Structural Defects (Measured in millimeters)

- Polishing Quality (Smoothness, Safety, Reflective Finish)

For stainless steel gua sha tools, grading is mainly based on:

- Polishing Quality

- Surface Integrity

This factory-defined system allows objective differentiation between A, B+, B, and C grades (for stone) and A vs B grades (for stainless steel).

Chapter 2 – Material Differences and Why They Matter

Why Material Determines Quality Criteria

Every gua sha tool starts from a raw material. Different materials carry different natural properties and therefore require different expectations. For example:

- Rose quartz naturally contains internal mineral snowflakes.

- Jade varies widely in color purity depending on origin.

- Amethyst may include natural inclusions or slight color zoning.

- Stainless steel is engineered and has no natural inclusions, so appearance should be near-perfect if properly polished.

Because of these differences, grading cannot be universal across materials.

How Factories Source Crystal Materials

Stone gua sha tools typically come from bulk mineral blocks sourced from Brazil, Madagascar, India, or China. During production:

- Color differences appear between blocks.

- Pits and natural cracks often exist inside the raw mineral.

- Translucency and depth can vary dramatically.

These natural variations heavily influence the final grade.

Chapter 3 – The Three Core Quality Dimensions for Crystal Gua Sha Tools

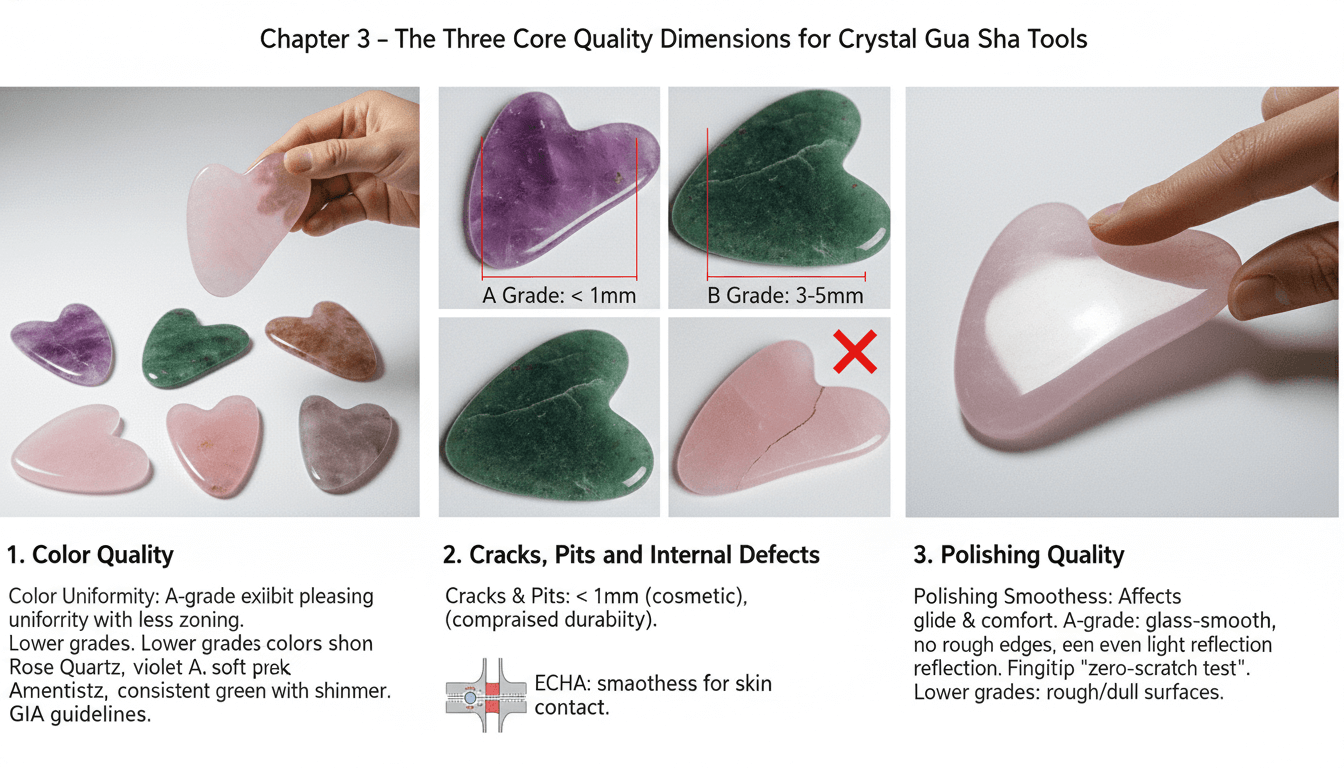

1. Color Quality – The First Visual Benchmark

Purity and Color Correctness

Color is the most noticeable indicator of quality. For example:

- Rose quartz should appear soft pink with a stable hue.

- Amethyst should have a violet tone without turning overly brown or grey.

- Green aventurine should show consistent green with visible mica shimmer.

According to GIA’s mineral identification guidelines, color consistency and mineral purity are key components in gemstone quality evaluation.

Color Uniformity

A-grade tools come from blocks with:

- fewer color patches,

- less dramatic zoning,

- visually pleasing uniformity.

Lower grades show uneven colors or multiple distracting tones.

2. Cracks, Pits, and Internal Defects

Measuring Cracks Clearly

Our factory uses measurable criteria:

- A Grade: cracks or surface pits smaller than 1 mm

- B+ Grade: cracks 1–3 mm

- B Grade: cracks 3–5 mm

- C Grade: cracks larger than 5 mm

These are natural features but influence the tool’s structural reliability and visual appeal.

Impact on Safety

Small cracks (<1 mm) are typically cosmetic. However, cracks exceeding 3–5 mm compromise durability or smoothness. The European Chemicals Agency (ECHA) reminds consumers that surface safety is relevant to skin-contact items, making smoothness an important indicator.

3. Polishing Quality – The Most Critical Functional Factor

Importance of Polishing Smoothness

Polishing is crucial because:

- It directly affects glide performance.

- It determines whether the tool is comfortable on skin.

- It prevents micro-abrasions, which might irritate sensitive skin.

What Perfect Polishing Looks Like

An A-grade polish:

- feels glass-smooth,

- has no rough edges,

- reflects light evenly,

- and passes a fingertip “zero-scratch test.”

Rough or dull surfaces indicate lower grades.

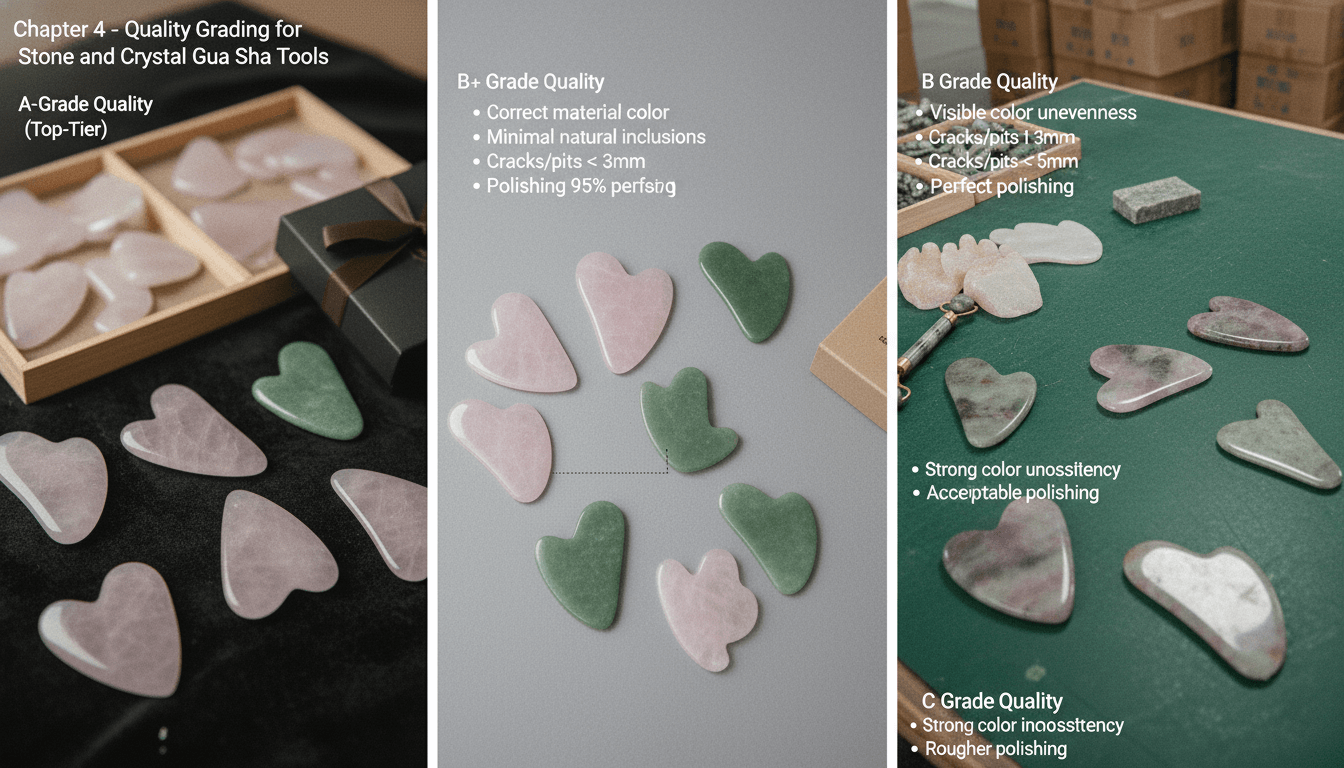

Chapter 4 – Quality Grading for Stone and Crystal Gua Sha Tools

A-Grade Quality (Top-Tier)

A-grade tools match the highest factory standards:

- Correct material color

- Minimal natural inclusions

- Cracks or pits < 1 mm

- Perfect polishing, no sharp edges

- No processing marks or visible grinding lines

Suitable for premium brands, gift boxes, and retail packaging.

B+ Grade Quality

Still high quality but with minor cosmetic variation:

- Color deviations but still aesthetically acceptable

- Cracks or pits 1–3 mm

- Polishing 95% perfect with slight micro-flaws not affecting use

Best for mid-tone retail brands or affordable wellness lines.

B Grade Quality

Moderate-grade with more noticeable flaws:

- Visible color unevenness

- Cracks 3–5 mm

- Polishing quality acceptable but not visually refined

Often used in spa bulk orders or budget-friendly portfolios.

C Grade Quality

Entry-level with clear visible imperfections:

- Strong color inconsistency

- Cracks > 5 mm

- Rougher polishing

- Cosmetic issues noticeable even from distance

Suitable for low-price wholesale markets, not recommended for premium branding.

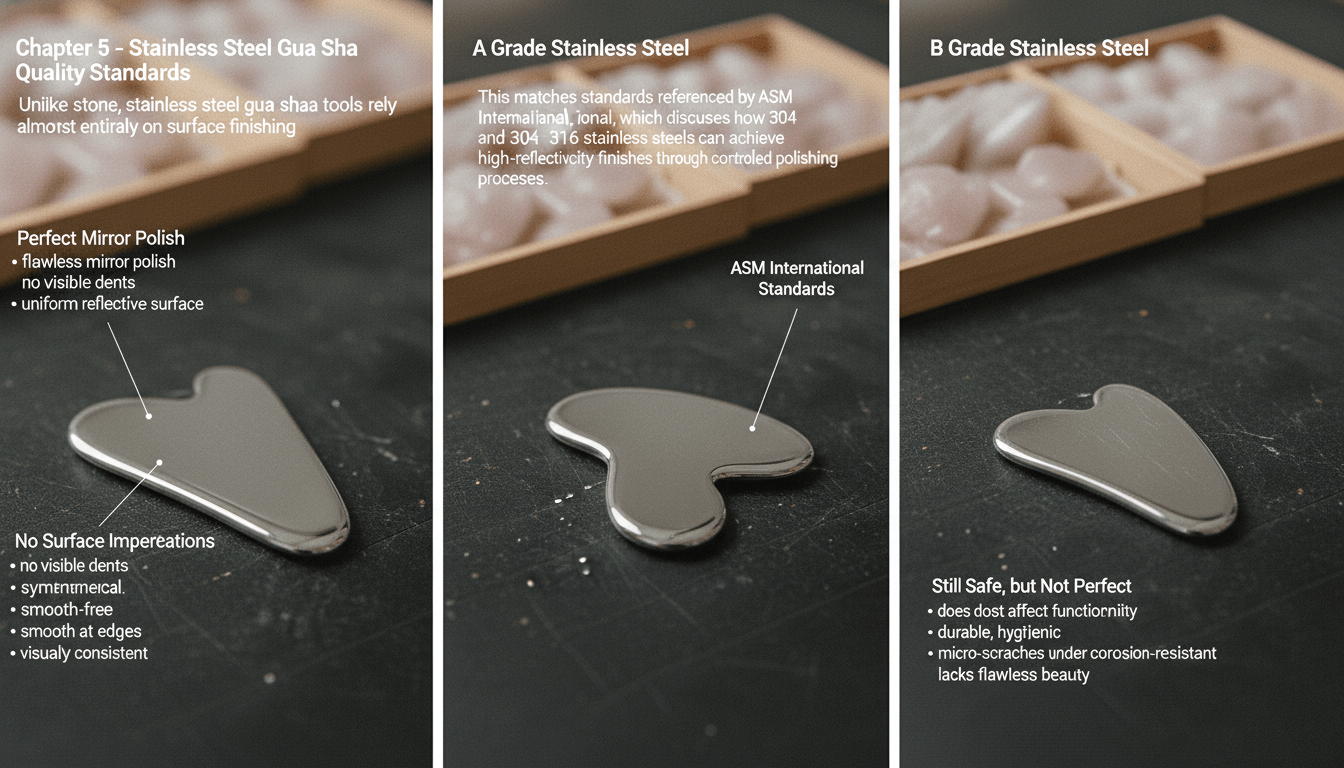

Chapter 5 – Stainless Steel Gua Sha Quality Standards

Unlike stone tools, stainless steel gua sha tools rely almost entirely on surface finishing.

A Grade Stainless Steel

Perfect Mirror Polish

A-grade stainless steel tools feature:

- flawless mirror polish

- no visible dents

- no brushing marks

- uniform reflective surface

This matches standards referenced by ASM International, which discusses how 304 and 316 stainless steels can achieve high-reflectivity finishes through controlled polishing processes.

No Surface Imperfections

A-grade tools must be:

- scratch-free

- symmetrical

- smooth at all edges

- visually consistent

B Grade Stainless Steel

Minor Surface Marks

B-grade pieces may include:

- tiny polishing swirls

- light surface shading

- micro-scratches under strong lighting

Still Safe, but Not Perfect

B-grade does not affect functionality. The steel remains durable, hygienic, and corrosion-resistant. However, it lacks the flawless beauty expected by premium brands.

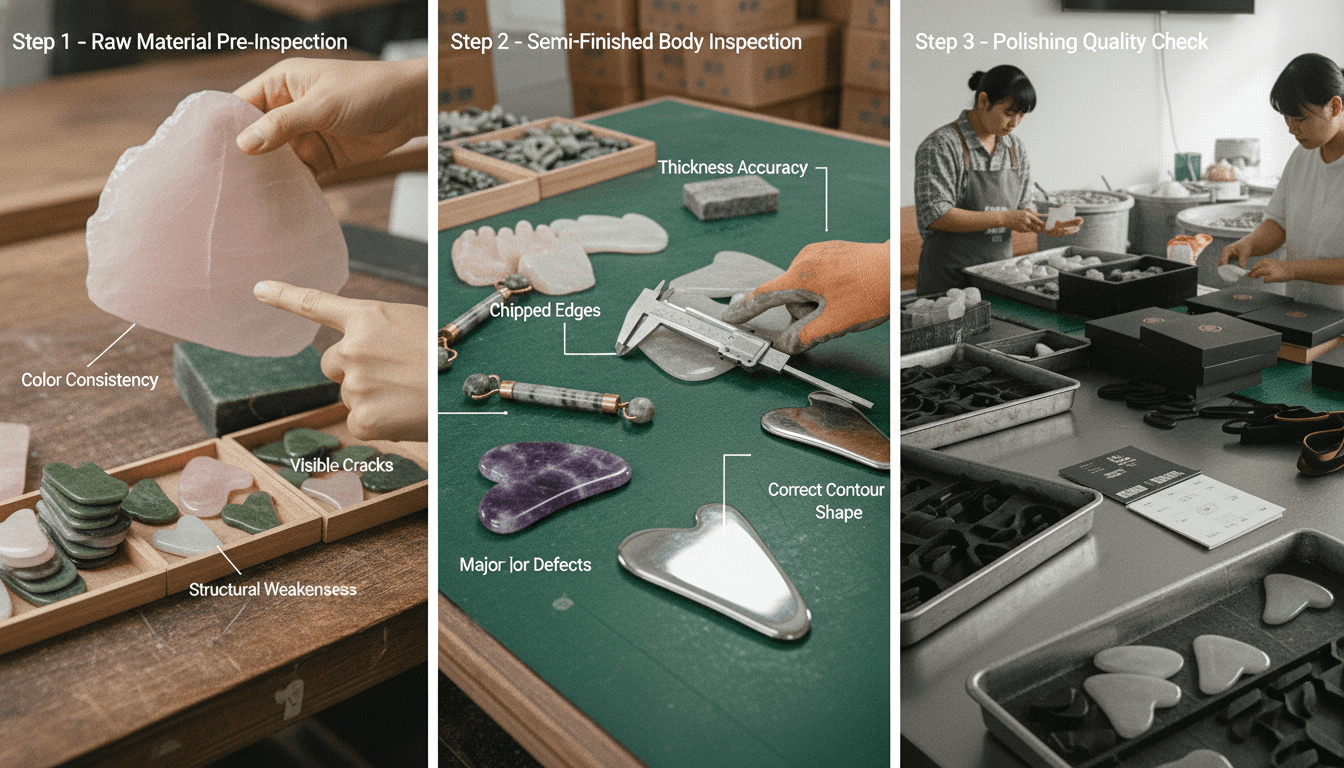

Chapter 6 – How Factories Conduct Quality Inspection

Step 1 – Raw Material Pre-Inspection

Factories inspect mineral blocks for:

- color correctness

- consistency

- visible cracks

- structural weaknesses

Workers cut the block into slabs and categorize them before shaping begins.

Step 2 – Semi-Finished Body Inspection

After shaping, every piece is checked for:

- thickness accuracy

- correct contour shape

- large cracks

- chipped edges

Pieces with major defects are eliminated early.

Step 3 – Polishing Quality Check

Polishing lines typically involve 3–7 rounds of grinding and finishing. After each round, workers check whether:

- edges remain smooth

- no scratches form

- the final gloss is forming evenly

Step 4 – Final Grading

Each piece is graded into A, B+, B, or C categories (stone) or A/B categories (steel).

This grading is 100% manual, based on experience — which is why factories vary widely in quality consistency.

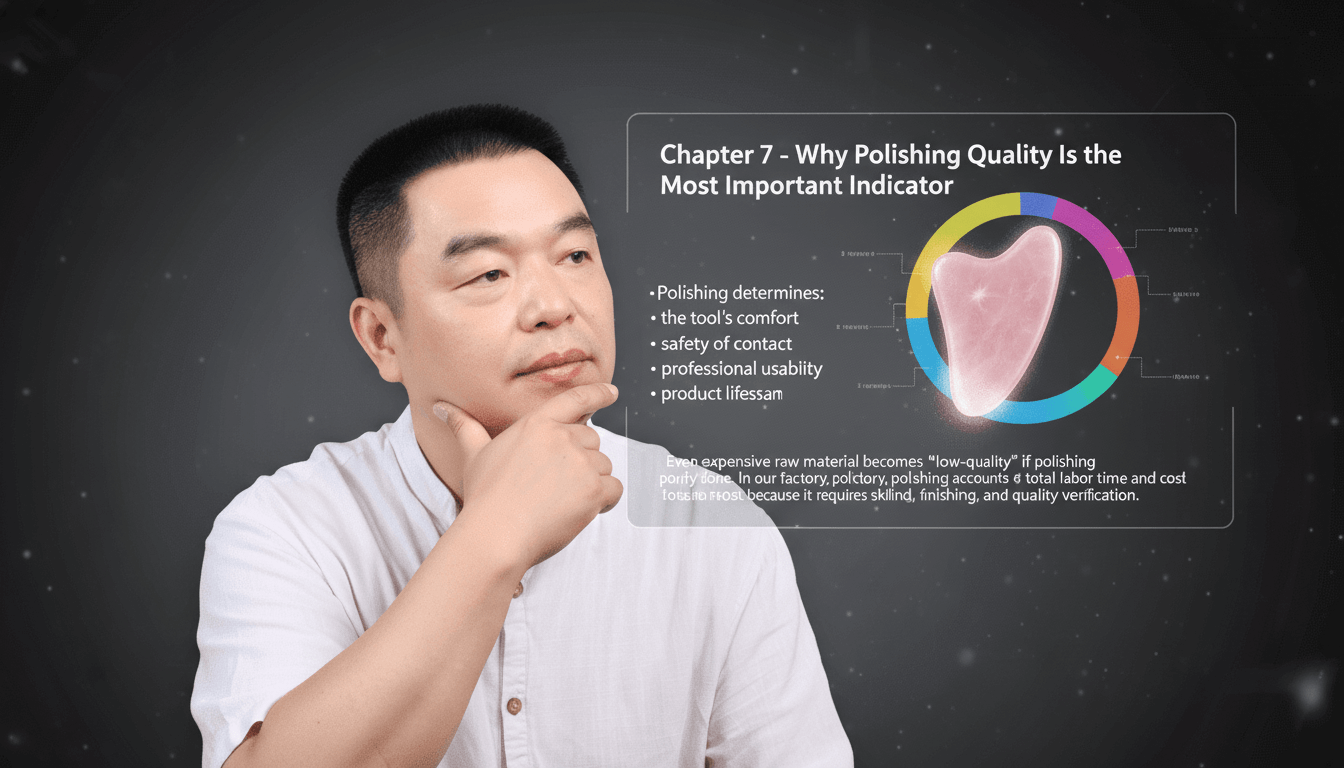

Chapter 7 – Why Polishing Quality Is the Most Important Indicator

Polishing determines:

- the tool’s comfort

- safety of contact

- professional usability

- product lifespan

Even expensive raw material becomes “low-quality” if polishing is poorly done. In our factory, polishing accounts for 40–50% of total labor time and cost because it requires skilled sanding, finishing, and quality verification.

Chapter 8 – How Brands Should Evaluate Their Supplier’s Quality Claims

1. Request Real Grading Samples

A reliable factory should provide:

- A-grade samples

- B+ grade samples

- B grade samples

- C grade samples

This helps brands compare actual differences.

2. Request Videos from the Production Line

Authentic factories can show:

- raw material cutting

- polishing stations

- QC tables

- grading procedures

Lighting and angles matter — poor factories avoid close-ups.

3. Ask Which GIA or Mineral Data Applies

Factories using mineral-verified suppliers often reference:

- GIA mineral identification

- Mohs hardness data

- Geographic sourcing details

This builds trust and prevents fake crystal issues.

4. Ask for Stainless Steel Certificates

For steel products, request:

- 304 or 316 stainless steel certificates

- documentation aligned with material-science standards (ASM International)

Chapter 9 – Why High-Quality Gua Sha Tools Cost More

Cost differences come from:

- material purity

- polishing time

- defect rejection rate

- manpower

- machine precision

- yield rate

For premium A-grade tools:

- up to 20–40% of material can be discarded due to cracks

- polishing requires 3–7 cycles, taking 2–5 hours

- defect inspection removes 10–25% of semi-finished pieces

Lower-grade factories skip most of these steps, resulting in lower prices but also lower quality.

Chapter 10 – Final Conclusion: What “Gua Sha Quality” Should Mean to You

“Gua sha quality” is more than color or material type. It is the combined reflection of:

- ethical sourcing

- real mineral purity

- measurable crack size

- correct polishing

- professional grading

- and transparent production

When a supplier provides clear, measurable, and consistent standards, brands and buyers gain confidence. At Deyi Gems, our factory’s grading system allows customers to know exactly what they are buying — whether A-grade premium tools or price-optimized lower-grade options.