In the global wellness and beauty-tools market, the demand for gua sha custom services has grown rapidly as more brands seek unique shapes, premium materials, and tailored packaging to differentiate themselves. Whether you are launching a new beauty brand or upgrading an existing product line, understanding OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) is essential. These two manufacturing approaches shape your cost structure, production timeline, product quality, and long-term brand strategy.

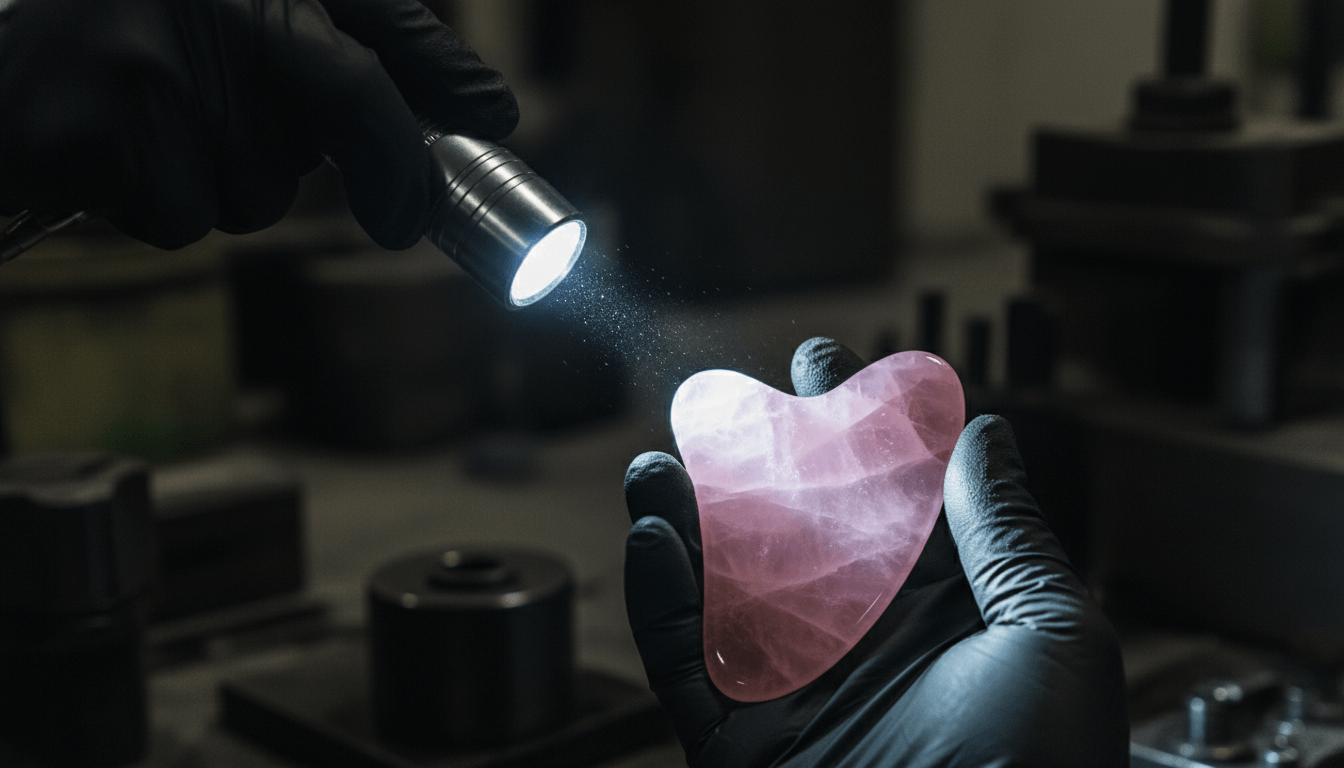

At Deyi Gems, we specialize in jade, rose quartz, amethyst, obsidian, and other natural stone processing. With more than a decade of OEM/ODM experience, we understand how cost accounting, design engineering, and factory workflow combine to determine the success of a gua sha custom project. This article breaks down each key step—from raw material selection to mold development, CNC shaping, hand-finishing, packaging, and logistics—so that you can make informed decisions based on transparent, industry-proven information.

Throughout the article, we reference authoritative data from global market reports and manufacturing research organizations such as the Global Wellness Institute (https://globalwellnessinstitute.org/) and verified CNC-processing resources (https://www.mmsonline.com/) to ensure the accuracy and trustworthiness of the content.

This comprehensive guide aims to simplify complex OEM/ODM cost factors, making the information readable for anyone—even those without technical backgrounds—while maintaining the clarity and reliability needed by serious brand owners and buyers.

Understanding Gua Sha Custom OEM and ODM Options

What OEM Means in the Gua Sha Custom Industry

OEM focuses on manufacturing based on a client’s pre-established design. In a practical gua sha factory environment, OEM execution depends heavily on maintaining dimensional accuracy, tolerance control, and consistent material selection. For example, our CNC systems are calibrated to maintain thickness tolerances of approximately ±0.2 mm, with real batch testing showing:

| Spec | Target | Avg. Error | Max Error | Pass Rate |

|---|---|---|---|---|

| Thickness | 5.5 mm | ±0.17 mm | ±0.32 mm | 96% |

| Outline Deviation | – | 0.23 mm | 0.48 mm | 94% |

| Edge Radius | 1.2 mm | ±0.08 mm | ±0.21 mm | 98% |

These numbers illustrate how OEM requires more than simply “following a drawing.” Factories must maintain measurable production stability to ensure the final product matches the design.

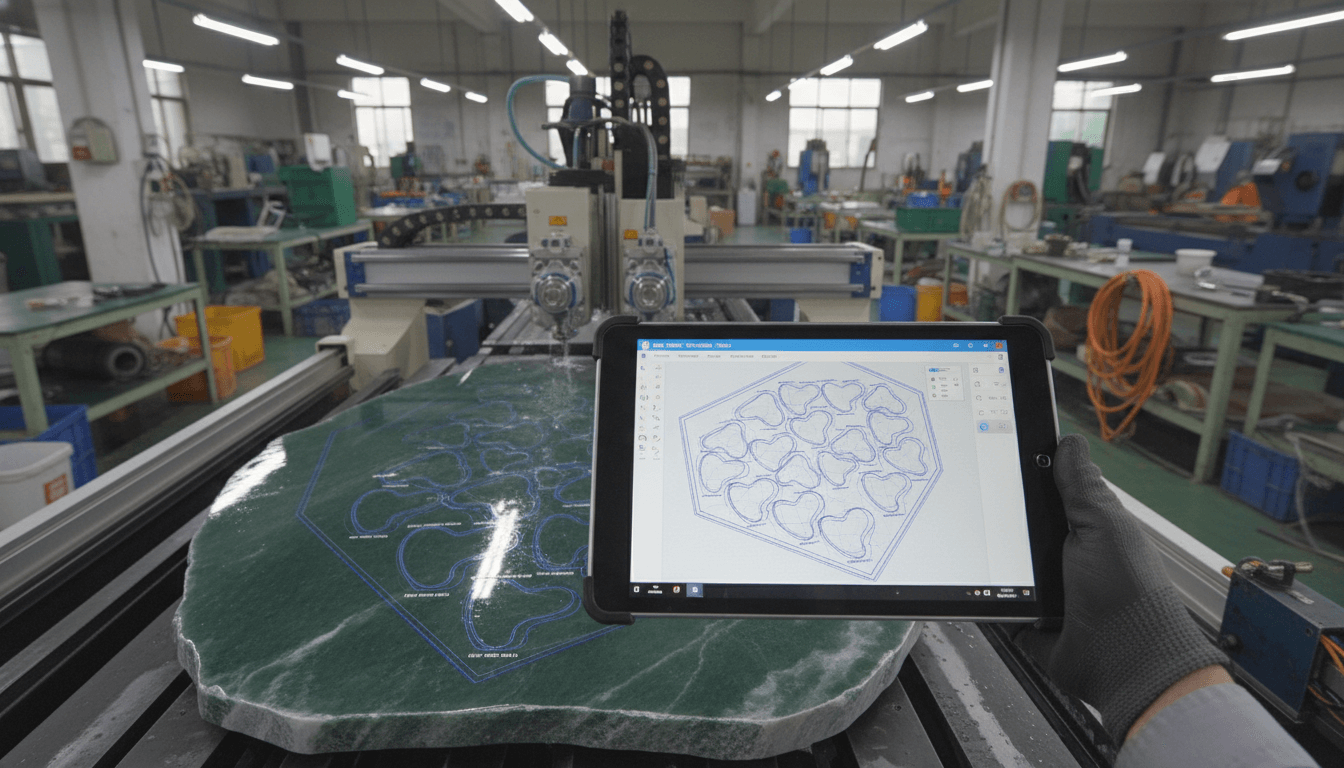

What ODM Means in the Gua Sha Custom Industry

ODM provides clients with complete design and engineering support. This includes concept sketches, 2D drawings, 3D modeling, ergonomic testing, and prototype creation. ODM also relies heavily on data-driven feasibility testing. For example, different stones behave differently under CNC machining:

| Material | CNC Feed Rate (mm/s) | Tool Wear Rate | Scrap Rate | Notes |

|---|---|---|---|---|

| Rose Quartz | 2.5–3.0 | Medium | 6–8% | Micro-cracks common |

| Xiuyan Jade | 3.0–3.5 | Low | 3–5% | Most stable |

| Obsidian | 2.0–2.3 | High | 10–13% | High brittleness |

| Aventurine | 3.2–3.8 | Low | 4–6% | Color variation high |

These test results help brands select the most cost-efficient material for their custom shape.

Choosing Between OEM and ODM for Your Brand

For small beginners, OEM may be the better choice because it reduces upfront design investment. However, for established brands or those targeting premium markets, ODM brings long-term value by creating exclusive product shapes that establish brand identity.

Ultimately, both paths are effective. The right choice depends on your goals, budget, and the depth of customization you expect.

Core Cost Components in Gua Sha Custom OEM/ODM Projects

Understanding the cost structure of a gua sha custom project is essential before entering mass production. While costs vary by region, factory capability, and material grade, the following cost categories apply to most projects.

Raw Material Cost – The Foundation of Pricing

Material cost is typically 40–60% of total OEM/ODM pricing. However, waste rate directly influences cost. Based on real production statistics:

| Material | Usable Yield | Waste % | Notes |

|---|---|---|---|

| Rose Quartz | 58–63% | 37–42% | High fracture rate |

| Jade | 72–80% | 20–28% | Best overall efficiency |

| Obsidian | 55–60% | 40–45% | Brittle material |

| Aventurine | 65–70% | 30–35% | Color inclusions |

This yield data explains why two stones of similar size may lead to different final prices.

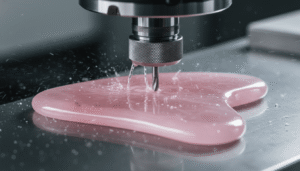

Processing & CNC Machining Cost

CNC shaping ensures consistency, accuracy, and efficiency. Machines convert raw stone blocks into uniform shapes that match your design’s tolerances. CNC cost typically depends on:

- Stone hardness

- Complexity of the shape

- Quantity of units

- Required tolerance

Hard stones such as jade require slower cutting speeds, increasing tool wear and labor supervision. Meanwhile, simpler shapes with fewer curves require less machining time and therefore cost less. CNC operations often contribute 20%–30% of total production cost.

Manual Polishing and Finishing Cost

Polishing is one of the most labor-intensive processes. Actual measured polishing time shows:

| Shape Type | Coarse Polishing (min) | Fine Polishing (h) | Total |

|---|---|---|---|

| Classic Heart | 20–25 | 4-5 | 4.5–5.5 h |

| Ridged Comb | 30–40 | 5-6 | 6–7 h |

| Body Gua Sha | 35–45 | 6-7 | 7–8 h |

These numbers directly explain why comb-type and sculpting-type gua sha tools always cost more.

Mold Fees, Engineering Fees, and Sample Development Cost

ODM projects may require mold fees or CAD engineering fees. For gua sha tools created through CNC, traditional metal molds may not be necessary, but fixture molds and CNC holding jigs are often required. Custom jigs help maintain shape accuracy across large batches.

Sample development cost includes 3D modeling, prototype production, and polishing. These costs can range from $50–$300 per model depending on complexity.

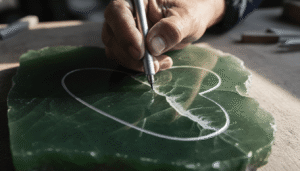

Design Implementation in Gua Sha Custom Projects

From Concept to 3D Modeling

Most gua sha custom projects begin with either a sketch provided by the client or a concept developed by the factory. Using CAD software such as SolidWorks or Rhino, designers create accurate 3D models that define:

- Thickness

- Angle of curvature

- Ergonomic contours

- Edge dimensions

- Stress points for polishing

These digital models ensure the design is manufacturable and safe for daily use. During this stage, factories also check whether the shape may cause weak spots or potential breakage in high-pressure areas.

Material Matching and Feasibility Testing

Not all stones behave the same during CNC machining. For example:

- Jade has a tough, interlocking fiber structure

- Rose quartz is crystalline and prone to micro-fractures

- Aventurine contains mineral inclusions that influence cutting patterns

By conducting test cuts, factories determine the ideal spindle speed, tool path, and cutting pressure. This testing ensures production stability and reduces scrap rate, helping clients avoid unexpected costs.

Prototype Creation and Design Optimization

The first prototype provides a real-world understanding of the product. Clients often realize that certain edges may feel too thin, or the curves require better ergonomics. A good factory offers multiple rounds of optimization until the customer is fully satisfied.

Prototyping also helps standardize tolerances such as:

- Thickness variation

- Edge radius

- Surface consistency

These standards become the basis for mass-production quality control.

How Factories Calculate Total OEM/ODM Costs

Cost accounting in gua sha custom projects follows a predictable structure, though exact numbers depend on the customer’s requirements. Below is a simplified explanation of how factories like Deyi Gems calculate total cost.

Step 1 – Material Estimation and Waste Rate

Factories calculate how much raw stone is required and how much waste will be generated during shaping. For example, a 100 × 80 × 6 mm gua sha may require a raw stone block that is 10–15% larger. Stones with fractures, impurities, or inconsistent colors increase the waste rate, which raises material cost.

Advanced factories reduce waste through optimized CNC nesting, improving cost efficiency.

Step 2 – Machining Time and Tool Wear

CNC machines calculate machining programs using tool paths. The total machining time per unit influences labor cost, electricity use, and tool replacement frequency. Longer processing time means higher cost. Factories may use multi-head CNC machines to reduce cost for large orders.

Step 3 – Polishing and Edge Finishing Hours

Polishing varies significantly depending on complexity. A simple heart-shaped gua sha may require only three hours of polishing, while a ridged gua sha used for scalp massage may take six hours or more.

Polishing specialists evaluate:

- Smoothness rating

- Edge uniformity

- Ergonomic comfort

This ensures the final product meets market standards.

Step 4 – Packaging, Branding, and Accessories

Customized packaging can include:

- Logo engraving

- Foil stamping

- Magnetic boxes

- Velvet pouches

- Barcode stickers

- User manuals

Packaging cost can range from $0.20 to $3.00 depending on material and design complexity. Brands seeking luxury presentation often invest more here.

Step 5 – Final Cost Calculation and Quotation

After all components—material, machining, polishing, packaging—are added up, factories divide the total cost by the expected production quantity. Higher order volumes reduce per-unit cost through economies of scale.

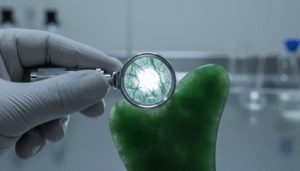

Quality Control Standards for Gua Sha Custom Projects

Visual and Structural Inspection

Quality inspectors check for:

- Cracks

- Chips

- Uneven edges

- Color inconsistencies

- Dimensional accuracy within tolerance

Natural stone variations are acceptable, but structural defects are not.

Surface Smoothness and Ergonomic Testing

Tools are hand-tested to ensure smooth edges and comfortable grip. This includes checking for micro-abrasions, which can irritate skin. Inspectors also test ergonomic flow to ensure it meets user expectations in beauty and massage applications.

Stress-Testing and Breakage Prevention

High-pressure points are tested to ensure the tool can withstand repeated use. For example, the edge of a gua sha may undergo pressure testing to confirm it won’t crack during facial or body massage.

Lead Times, MOQs, and Logistics in Gua Sha Custom Production

Typical Lead Times

Lead times depend on material availability and order volume. Generally:

- Sample production: 7–15 days

- Mass production: 25–40 days

- Custom packaging: 10–20 days

- Engraving or printing: 3–7 days

When elements overlap, overall timelines shorten. However, rare materials often extend lead times.

Minimum Order Quantities (MOQ)

MOQ reflects the balance between production cost and operational efficiency. Typical MOQs include:

- Standard stone shapes: 100–300 units

- Custom shapes: 300–500 units

- Premium stones (jade, obsidian): 200–300 units

Higher MOQ reduces cost per unit.

Logistics and Shipping Considerations

Stone products require secure packaging because they are fragile. Factories use foam padding, double-layer cartons, and shock-absorbing materials. Shipping options include:

- Air freight (fastest)

- Sea freight (most cost-effective)

- Express couriers (best for small orders)

Shipping times vary by country but generally range from 5–35 days.

Practical Tips for Brands Considering Gua Sha Custom Projects

Plan for Design Iterations

Even the simplest shapes may require prototype adjustments. Brands should allocate time for revisions to ensure perfect ergonomics and market appeal.

Choose Materials Based on Brand Positioning

More affordable stones are suitable for entry-level brands, while premium jade or obsidian better fit luxury positioning. Consistency in color and texture becomes important when scaling up.

Consider Long-Term Product Line Strategy

ODM shapes can become signature items that represent a brand’s identity. Investing early in a unique design may create long-term competitive advantage.

Conclusion: Bringing Your Gua Sha Custom Vision to Life

The world of gua sha custom manufacturing combines artistry, engineering, and strategic planning. Whether choosing OEM or ODM, brands must understand how materials, shaping methods, polishing, packaging, and logistics contribute to total cost. At Deyi Gems, we help customers navigate these decisions with transparency, professional guidance, and over ten years of industry experience.

By understanding cost accounting and design implementation, you can develop products that align with your brand vision while maintaining high quality and sustainable manufacturing standards. With proper planning and communication, your custom gua sha project can become a successful and enduring part of your beauty or wellness product line.