Standardized gua sha tools no longer meet today’s market needs. As competition intensifies, brands struggle to differentiate and maintain perceived value. This shift pushes professional buyers toward experienced manufacturers capable of true custom gua sha tools. Differentiation comes from four areas:

- Material quality → Improves durability and consistency, reducing defect-related returns.

- Ergonomic shape → Enhances user experience and repeat purchase potential.

- Surface finish → Elevates perceived value and supports premium pricing.

- Brand integration → Strengthens brand recognition and long-term market differentiation.

DeYi Gemstone focuses on jade and natural stone processing. We specialize in OEM and ODM manufacturing of gua sha tools. Customization is not a single action, but a series of standard steps from material selection to final delivery.

Each custom gua sha project follows clear production stages. Only when each step is properly controlled can customized gua sha tools meet both functional and commercial expectations.

- What Is Custom Gua Sha Tool Manufacturing?

- Raw Material Selection for Custom Gua Sha Tools

- Custom Gua Sha Model Design and Engineering

- Mold-Free vs Mold-Based Custom Gua Sha Approaches

- Surface Finishing and Edge Treatment

- Logo and Branding Integration for Custom Gua Sha Tools

- Quality Control in Gua Sha Factory Production

- Packaging Compatibility and Customization Considerations

- Custom Gua Sha Tools Production Capacity and Lead Time Management

- Compliance and International Trade Considerations

- Choosing the Right Custom Gua Sha Factory and Manufacturer

- Conclusion: The Value of Professional Custom Gua Sha Tool Manufacturing

What Is Custom Gua Sha Tool Manufacturing?

Definition from a Factory Perspective

From a manufacturing perspective, custom gua sha production is driven by client-defined specifications. It follows clear requirements rather than fixed templates. This is what distinguishes it from off-the-shelf designs.

Customization may include:

- Material

- Thickness

- Curvature

- Edge geometry

- Surface finish

- Logo application

- Packaging compatibility

This approach allows each gua sha tool to be produced to fit a specific market, usage scenario, and brand position, instead of adapting to a pre-made mold.

True customization is not private labeling.

Private labeling adds a brand to an existing product. True customization builds the product from defined requirements.

It requires coordination across key functions:

- Design & engineering – Convert concepts into workable specifications.

- Stone processing & manufacturing – Execute shapes, tolerances, and finishes accurately.

- Quality control & production planning – Maintain consistency while meeting delivery schedules.

Only with this coordination can a gua sha design move from idea to stable, repeatable production.

Why Customization Matters in the Gua Sha Industry

Gua sha tools are tactile products that interact directly with the skin. Even small changes in curvature, edge smoothness, or thickness can significantly affect user experience. This is why customization is not merely cosmetic, but functional.

Different regions have different preferences. North American facial gua sha tools favor lightweight bodies and smooth curves. Traditional therapy tools require thicker profiles and firmer edges.

How to choose:

- Facial use → lightweight, curved design

- Therapy use → thicker body, hard edges

Raw Material Selection for Custom Gua Sha Tools

Natural Stone Types Commonly Used

Material selection is the foundation of custom gua sha manufacturing. As a jade and gemstone processing factory, we work with a wide range of natural stones, each with unique physical and aesthetic characteristics.

Jade (including nephrite and jadeite) remains the most traditional choice due to its density, fine grain structure, and smooth polishability. Other materials such as rose quartz, amethyst, obsidian, aventurine, and bian stone are also widely used in modern gua sha tools. Each stone differs in hardness, brittleness, and surface behavior during carving and polishing.

Understanding these material properties is essential for determining feasible shapes and thicknesses. For example, brittle stones require gentler curvature transitions to reduce breakage risk during production.

Material Quality Standards in Manufacturing

Professional gua sha factories apply internal grading standards to control stone consistency. Visual checks focus on cracks, internal inclusions (such as mineral spots or cloudy lines inside the stone), and color variation (uneven tone between batches or within one piece).

Poor raw material selection causes defects during carving or polishing. This raises rejection and rework rates. As a result, production costs increase and delivery timelines are extended.

Industry gemstone standards guide manufacturers in grading raw materials. They help check stone structure, spot internal flaws, and compare color consistency. For example, the Gemological Institute of America (GIA) provides reference methods to identify cracks, cloudy inclusions, and uneven coloration when inspecting incoming stones.

Gemological Institute of America (GIA) — authoritative guidelines on gemstone structure, inclusions, and quality evaluation: https://www.gia.edu

Custom Gua Sha Model Design and Engineering

Translating Custom Gua Sha Concepts into Manufacturable Designs

Custom model development typically follows these steps:

- Optimization – Adjustments are made to improve manufacturability, ergonomics, or appearance.

- Sketch / Concept – Client provides sketches, reference samples, or digital drawings.

- Feasibility Assessment – Manufacturer checks if the design can be made efficiently with natural stone.

- Prototype / Sample – A first sample is produced for review and testing.

Stone is rigid and cannot bend like resin or metal. Certain design features can cause problems during production. For example, extremely thin edges or sharp internal angles will lead to breakage.

Experienced factories suggest adjustments to improve manufacturability while keeping the original look:

- Overall curvature – Slightly modify curves to balance aesthetics and strength.

- Edge thickness – Increase thin edges to prevent chipping.

- Internal corner radius – Soften sharp angles to reduce fracture risk.

- Tool contact points – Adjust pressure zones to avoid cracks during polishing.

Ergonomic Considerations in Custom Gua Sha Model

Ergonomics is a key focus in gua sha model customization. Facial gua sha tools must align with facial contours, jawlines, and neck muscles. This requires precise control over curve radius, edge width, and contact surface area.

Manufacturers often produce small trial batches or prototypes to test grip comfort and stroke efficiency. These evaluations help refine the model before mass production begins.

Mold-Free vs Mold-Based Custom Gua Sha Approaches

Hand-Cut and CNC-Assisted Processing

In traditional stone gua sha manufacturing, most tools are produced without molds. Instead, CNC machines or skilled craftsmen cut the basic shape directly from stone slabs, followed by manual grinding and polishing.

This mold-free approach offers greater flexibility for customization, especially for low to medium order quantities. Design changes can be implemented quickly without the cost of mold development.

When Mold-Based Custom Gua Sha Production Is Applicable

In rare cases where composite stone or engineered materials are used, mold-based production may be possible. However, for natural jade and gemstone gua sha tools, mold usage is limited due to material constraints.

For brands seeking authenticity and natural variation, mold-free production remains the preferred method and aligns with consumer expectations for genuine stone products.

Surface Finishing and Edge Treatment

Polishing Levels and Tactile Feel

Surface finish influences both appearance and tactile experience.

- Satin / velvet finish – Soft and matte; suits natural or wellness-focused brands; offers a gentle, grippy touch during use.

- High-polish finish – Shiny and reflective; conveys premium branding; feels smooth and luxurious on the skin.

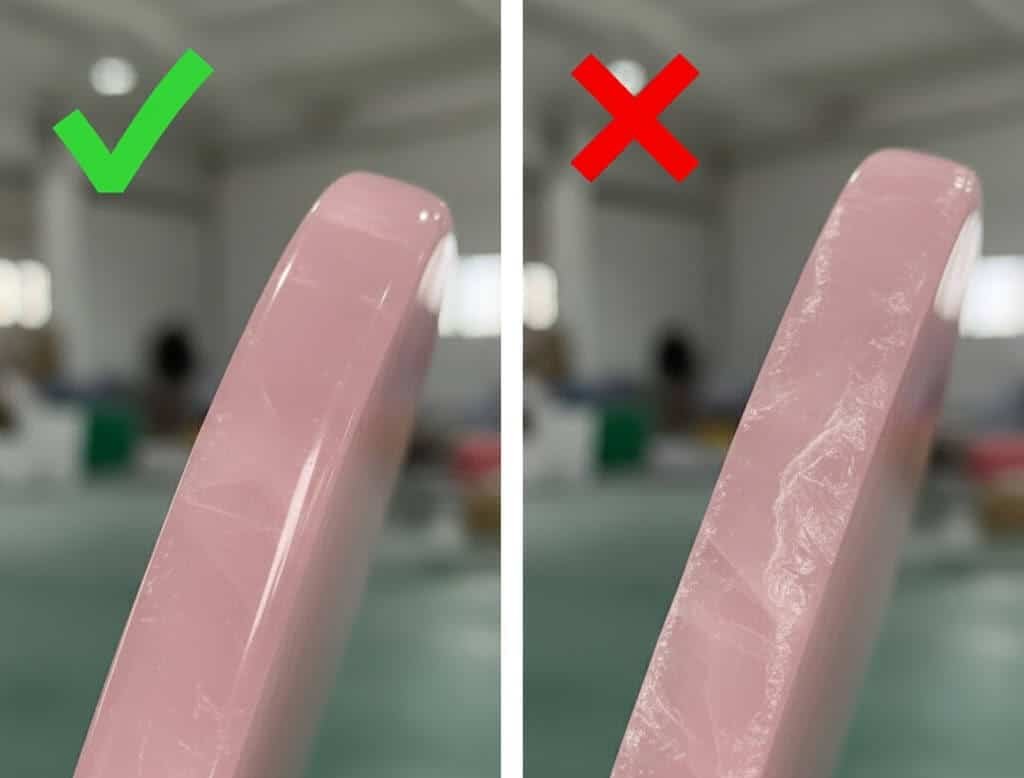

Achieving consistent polish across large batches requires controlled polishing time and abrasive selection. Over-polishing may alter dimensions, while under-polishing results in surface drag during use.

Edge Geometry and Safety Standards

All contact edges on personal care tools must be smooth and free of burrs, as emphasized by the U.S. Consumer Product Safety Commission (CPSC); rough edges or tiny splinters can scratch or irritate the skin during use.

Logo and Branding Integration for Custom Gua Sha Tools

Common Logo Application Methods

Logo customization in stone gua sha manufacturing requires careful consideration. Common methods include laser engraving, shallow stone carving, or indirect branding through packaging.

Because natural stone surfaces may contain micro-pores, adhesive logos or stickers are generally avoided due to durability concerns. Permanent marking methods are preferred for long-term brand integrity.

Balancing Visibility and Aesthetics

Effective branding does not overwhelm the natural beauty of the stone. Manufacturers often recommend subtle logo placement on non-contact areas to preserve functionality while maintaining brand recognition.

Quality Control in Gua Sha Factory Production

Dimensional and Visual Inspection

Quality control is integrated at multiple stages of production. After cutting, tools are checked for dimensional accuracy and symmetry. After polishing, surface consistency and edge smoothness are evaluated.

Natural stone variation is expected, but unacceptable defects such as cracks or sharp edges are systematically removed from production batches.

Batch Consistency for Wholesale Orders

For B2B clients, batch consistency matters as much as individual quality.

Factories keep reference samples and inspection checks to ensure repeat orders match previous shipments in size, finish, and appearance.

For example, stone dimensions are controlled within ±1 mm, and color differences are limited to a ΔE range that keeps shades visually consistent across the batch.

This level of consistency is essential for brands selling through retail or e-commerce channels, where customer expectations are high.

Packaging Compatibility and Customization Considerations

Designing Tools with Packaging in Mind

Custom gua sha model design often considers downstream packaging requirements. Tool thickness, length, and curvature affect how products fit into boxes, trays, or sets.

Early coordination between manufacturer and brand helps avoid costly redesigns later in the process.

Sustainability and Material Responsibility

Many brands now prioritize sustainable packaging. While stone tools themselves are long-lasting, packaging choices influence overall environmental impact. Guidance on sustainable packaging principles is available from organizations such as the Sustainable Packaging Coalition.

Custom Gua Sha Tools Production Capacity and Lead Time Management

Scaling from Prototype to Mass Production

A reliable gua sha manufacturer must support clients from initial sampling through scaled production. This involves production scheduling, workforce allocation, and raw material planning.

Custom models typically require longer lead times than standard designs, especially during the first production cycle. Transparent communication helps align expectations.

Long-Term Manufacturing Partnerships

For brands with recurring orders, forming a long-term partnership with a factory improves operational efficiency.

Three benefits of long-term factory partnerships:

- Reduced defects – Standardized specs and inspections cut errors. Example: defect rate drops from 8% → 3%.

- Shorter production cycles – Streamlined workflows speed up orders. Example: lead time decreases from 15 days → 12 days.

- Stable delivery – Consistent processes ensure on-time shipments. Example: on-time delivery rises from 85% → 98%.

Example: After six months of collaboration, one brand reported a 30% drop in defective units and a 20% faster production cycle for repeat orders.

Compliance and International Trade Considerations

Export Requirements for Stone Products

Natural stone gua sha tools must comply with export documentation and destination country regulations. This includes material declarations and, in some cases, origin certification.

Manufacturers experienced in international trade help clients navigate these requirements smoothly.

Truthful Product Representation

Why accurate labeling matters

- Material names must be accurate to meet regulations.

- Incorrect naming breaks consumer trust.

- It can lead to returns, complaints, or penalties.

Common mistake (example)

- ❌ “Pink Jade” → actually Rose Quartz

- Result: refunds, disputes, or fines.

Correct naming template

Use Material name + Treatment / Origin (if applicable).

Correct naming examples

- ✅ Natural Rose Quartz – Untreated

- ✅ Nephrite Jade – Canada Origin

- ✅ Green Aventurine – Heat Treated

This format is clear, compliant, and easy for buyers to understand.

Choosing the Right Custom Gua Sha Factory and Manufacturer

Key Indicators of Manufacturing Expertise

A professional gua sha factory demonstrates expertise through material knowledge, process transparency, and consistent quality outcomes.

Key criteria to evaluate a gua sha factory:

- Sample quality – Check shape accuracy, surface finish, and edge smoothness.

- Communication clarity – Assess responsiveness, clarity of answers, and ease of sharing requirements.

- Design feedback – Look for practical suggestions on manufacturability, ergonomics, and material adjustments.

Buyers should evaluate factories based on sample quality, communication clarity, and their ability to provide practical design feedback.

Why Deyi Gems Focuses on Custom Manufacturing

At Deyi Gems, we help clients get high-quality custom gua sha tools with minimal rework. Our expertise ensures consistent production and reliable on-time delivery. This reduces defects, shortens lead times, and keeps repeat orders predictable.

By controlling every step from raw stone selection to final inspection, we help brands bring distinctive, reliable products to market.

Conclusion: The Value of Professional Custom Gua Sha Tool Manufacturing

Key takeaways:

- Custom gua sha production requires deep material knowledge.

- Precise craftsmanship ensures functional and aesthetic quality.

- Structured quality control guarantees consistency and reliability.

- Customization is a strategic tool for brand differentiation.

For buyers: Start customization by focusing on materials, production processes, and quality inspection.

Partnering with an experienced gua sha factory reduces rework and ensures stable delivery schedules. Custom designs remain both attractive and fully functional.

Example: One client cut defect rates by 25% and improved on-time delivery by 15% after working with a skilled manufacturer.

At Deyi Gems, we remain committed to supporting global partners with reliable, transparent, and technically sound custom gua sha manufacturing solutions.