In the gua sha wholesale industry, logistics is not a supporting function—it is a core capability that directly affects business stability. After years of working with international distributors, spa chains, and private-label brands, we have seen that most disputes and losses do not come from product design, but from logistics misunderstandings.

According to the World Trade Organization (WTO), logistics-related costs typically represent 10–15% of total product cost in international trade, and inefficient logistics management can increase landed costs by up to 25%.

Source: World Trade Organization – Trade Facilitation and Logistics

https://www.wto.org/english/tratop_e/tradfa_e/tradfa_e.htm

For gua sha wholesale buyers, understanding the logistics process is not about becoming a freight expert. It is about knowing where risks exist, where costs are generated, and how responsibilities are divided between the supplier and the buyer.

- Chapter 1: What “Gua Sha Wholesale Logistics” Really Means

- Chapter 2: Factory-Level Preparation Based on Real Export Practice

- Chapter 3: Export Cartons, Labeling, and Palletization

- Chapter 4: Documentation Accuracy and HS Code Expertise

- Chapter 5: Transportation Choices Based on Order Reality

- Chapter 6: Incoterms and Risk Responsibility

- Chapter 7: Customs Compliance and Market-Specific Awareness

- Chapter 8: Delivery, Inspection, and Inventory Control

- Chapter 9: Logistics Risks Seen in Real Wholesale Operations

- Conclusion: Why Logistics Expertise Defines Professional Gua Sha Suppliers

Chapter 1: What “Gua Sha Wholesale Logistics” Really Means

Logistics Beyond Transportation

From a manufacturer’s point of view, gua sha wholesale logistics begins before the goods leave the factory. It includes quality verification, export packaging design, document accuracy, and shipment planning. Transportation is only one part of a longer and more complex chain.

In our experience, buyers who understand this full scope are better prepared to control costs and timelines. They also communicate more efficiently with suppliers and freight forwarders.

Why Gua Sha Products Require Special Attention

Gua sha tools are small, dense, and often fragile. Natural stone tools are prone to edge chipping, while stainless steel tools significantly affect freight weight calculations. These characteristics make generic logistics solutions unsuitable.

The International Air Transport Association (IATA) reports that around 5% of global air cargo shipments suffer damage or mishandling each year, with fragile consumer goods facing higher risk.

Source: IATA – Cargo Handling Standards

https://www.iata.org/en/programs/cargo/operations/

This is why experienced gua sha manufacturers treat logistics planning as part of product engineering.

Chapter 2: Factory-Level Preparation Based on Real Export Practice

Quality Control as a Logistics Foundation

In wholesale trade, logistics problems often amplify quality issues. From our experience, exporting products without proper inspection almost always leads to disputes at destination.

For this reason, most professional gua sha manufacturers apply AQL (Acceptable Quality Limit) standards before shipment. According to SGS, applying AQL 2.5 for major defects and AQL 4.0 for minor defects can reduce post-shipment disputes by over 30% in B2B trade.

Source: SGS – Acceptable Quality Limit (AQL) Explained

https://www.sgs.com/en/inspection-services/acceptable-quality-limit-aql

This step protects both the supplier and the buyer.

Packaging Decisions Driven by Logistics Reality

Packaging is not only about appearance. In real export scenarios, packaging decisions directly affect breakage rates, freight costs, and customs inspection outcomes.

Logistics providers such as DHL Global Forwarding note that inefficient packaging design can increase shipping costs by 20–40% due to dimensional weight calculations.

Source: DHL Global Forwarding

https://www.dhl.com/global-en/home/our-divisions/global-forwarding.html

At the wholesale level, professional packaging balances protection, cost efficiency, and compliance.

Chapter 3: Export Cartons, Labeling, and Palletization

Why Carton Information Matters in Practice

Clear carton labeling is often underestimated by buyers. In actual export operations, missing or unclear carton information frequently leads to customs inspection delays.

The World Customs Organization (WCO) indicates that incorrect or incomplete cargo information contributes to approximately 10% of physical inspections worldwide.

Source: World Customs Organization – Customs Procedures

https://www.wcoomd.org/en/topics/facilitation/overview.aspx

For gua sha wholesale shipments, this means longer clearance times and higher storage costs.

Palletization and ISPM 15 Compliance

When palletization is required, ISPM 15 compliance becomes non-negotiable. Wooden pallets must be heat-treated or fumigated to prevent pest transmission.

Non-compliant pallets may be rejected at destination ports. This is a risk we have seen repeatedly in real shipments.

Source: International Plant Protection Convention – ISPM 15

https://www.ippc.int/en/core-activities/standards-setting/ispm-15/

Chapter 4: Documentation Accuracy and HS Code Expertise

Why Documentation Errors Are Costly

From a manufacturer’s operational experience, documentation errors are among the most expensive logistics mistakes. Customs authorities rely on invoices and packing lists to assess duties and legitimacy.

Even small inconsistencies can trigger inspections or penalties.

HS Code Classification for Gua Sha Tools

Gua sha tools are commonly classified under HS Code 9019, covering massage apparatus, as defined by the World Customs Organization.

In the U.S., serious HS misclassification can result in penalties up to the domestic value of the goods.

Source: World Customs Organization – Harmonized System

https://www.wcoomd.org/en/topics/nomenclature/overview/what-is-the-harmonized-system.aspx

Correct classification reflects professional export capability.

Chapter 5: Transportation Choices Based on Order Reality

Air Freight in Real Wholesale Scenarios

Air freight is typically used for samples or urgent replenishment. However, it is not suitable for regular bulk orders.

According to IATA, air freight costs are usually 4–6 times higher per kilogram than sea freight, which directly affects landed cost calculations.

Source: IATA – Air Cargo Market Analysis

https://www.iata.org/en/iata-repository/publications/economic-reports/air-cargo-market-analysis/

Sea Freight as the Wholesale Standard

The United Nations Conference on Trade and Development (UNCTAD) reports that over 80% of global merchandise trade by volume is transported by sea, making it the backbone of wholesale logistics.

Source: UNCTAD – Maritime Transport

https://unctad.org/topic/transport-and-trade-logistics

From a manufacturer’s experience, proper production planning is essential when using sea freight.

Chapter 6: Incoterms and Risk Responsibility

Why Incoterms Protect Both Sides

Incoterms are not legal formalities. They define real responsibility boundaries.

These rules are published by the International Chamber of Commerce (ICC) and are widely accepted in global trade.

Source: International Chamber of Commerce – Incoterms®

https://iccwbo.org/resources-for-business/incoterms-rules/

Clear Incoterms prevent disputes before they happen.

Cargo Insurance from a Risk-Control Perspective

According to Allianz Global Corporate & Specialty, insured cargo losses represent less than 0.1% of insured shipment value annually.

Source: Allianz – Cargo Risk Report

https://www.agcs.allianz.com/news-and-insights/reports/cargo-risk-report.html

From experience, insurance is not optional for wholesale shipments.

Chapter 7: Customs Compliance and Market-Specific Awareness

U.S. Market Compliance Experience

In the U.S., gua sha tools are generally considered wellness or beauty accessories. However, improper medical claims can trigger FDA scrutiny.

The FDA’s General Wellness Policy explains this distinction clearly.

Source: U.S. Food & Drug Administration

https://www.fda.gov/regulatory-information/search-fda-guidance-documents/general-wellness-policy-low-risk-devices

Professional suppliers understand these boundaries.

Clearance Time and Documentation Quality

According to OECD data, average customs clearance time in developed economies is 1–3 days when documentation is complete.

Source: OECD – Trade Facilitation Indicators

https://www.oecd.org/trade/topics/trade-facilitation/

Chapter 8: Delivery, Inspection, and Inventory Control

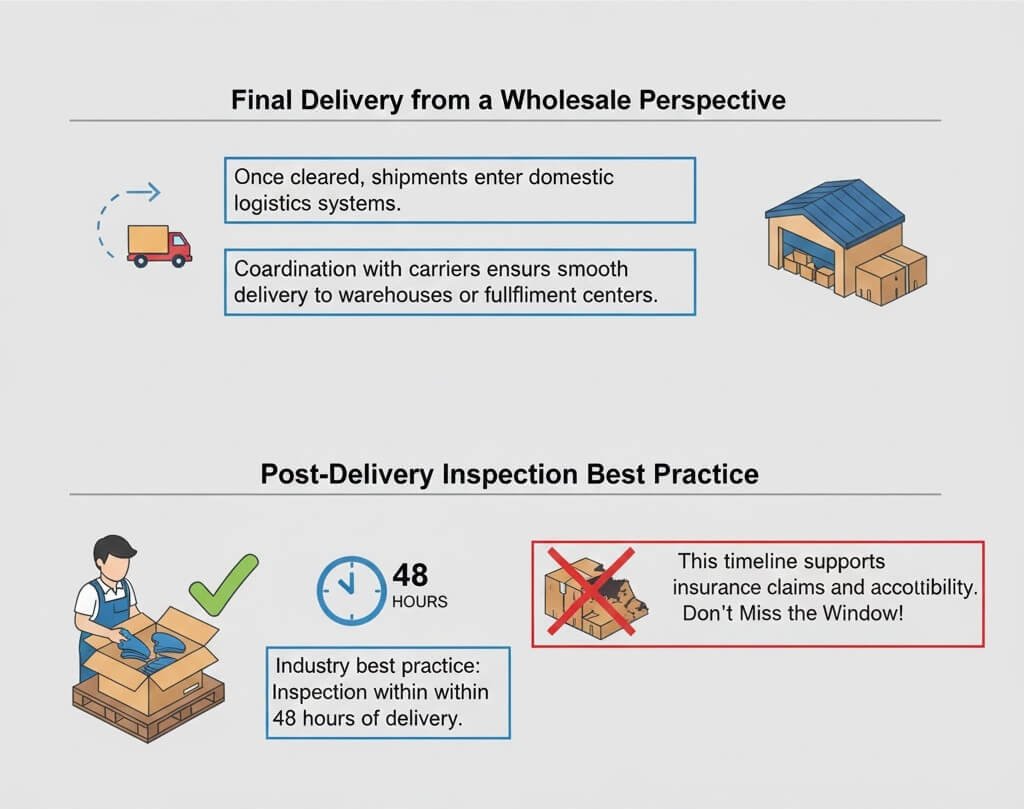

Final Delivery from a Wholesale Perspective

Once cleared, shipments enter domestic logistics systems. Coordination with carriers ensures smooth delivery to warehouses or fulfillment centers.

Post-Delivery Inspection Best Practice

Industry best practice recommends inspection within 48 hours of delivery. This timeline supports insurance claims and accountability.

Chapter 9: Logistics Risks Seen in Real Wholesale Operations

Cost Impact of Disruptions

The World Economic Forum reports that supply chain disruptions can increase landed costs by 5–10% due to delays, storage fees, and inventory shortages.

Source: World Economic Forum – Supply Chain Risk

https://www.weforum.org/topics/supply-chains-and-transport/

From experience, proactive logistics planning is the most effective risk control method.

Conclusion: Why Logistics Expertise Defines Professional Gua Sha Suppliers

Gua sha wholesale logistics is a system built on experience, process discipline, and transparency. For buyers, understanding this system improves decision-making. For manufacturers like Deyi Gems, logistics expertise is part of our professional responsibility.

When logistics is handled correctly, gua sha wholesale becomes predictable, scalable, and sustainable. That reliability is what defines a long-term manufacturing partner—not just a product supplier.