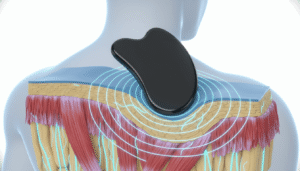

The gua sha tool has evolved from a traditional therapeutic instrument into a globally recognized beauty and wellness accessory. As facial gua sha becomes a mainstream skincare practice, demand for stone-based gua sha tools continues to grow across North America, Europe, and emerging wellness markets. This shift has pushed gua sha production from small-scale handcrafting toward standardized factory manufacturing.

However, while many discussions focus on stone type or surface appearance, the shape of a gua sha tool remains one of the most decisive factors in production feasibility and cost control. From a factory perspective, shape directly affects raw material utilization, finished yield rate, processing time, labor skill requirements, and unit economics.

At Deyi Gems, our long-term experience in gua sha factory operations shows that different gua sha tool shapes produce measurable, repeatable differences across every production stage. This article examines those differences using verifiable manufacturing logic, clearly defined measurement methods, and commercially relevant production data.

Understanding Gua Sha Tool Shapes in Modern Manufacturing

The Expansion of Shape Variety in the Beauty Market

Early gua sha tools were simple and functional, typically featuring flat or gently curved edges suitable for body scraping. As facial gua sha gained popularity, tool shapes became more refined and specialized. Modern designs include half-moon shapes, heart contours, comb-edge profiles, wave geometries, and multi-angle sculpted surfaces.

From a manufacturing standpoint, this expansion significantly increases production complexity. Each additional curve, concave area, or fine edge requires extra cutting paths, more polishing steps, and tighter quality control thresholds. In gua sha production, shape must therefore be treated as a core manufacturing parameter, not just a cosmetic decision.

Shape as a Fixed Constraint in Natural Stone Processing

Unlike polymer or metal tools, gua sha tools made from natural jade or quartz must conform to the stone’s internal structure. Grain direction, inclusions, and micro-fractures limit how aggressively a shape can be cut or polished. As shape complexity increases, tolerance for error decreases, making certain designs inherently less stable at scale.

This constraint explains why some visually appealing gua sha tool designs perform well at prototype level but encounter high defect rates during commercial production.

Raw Material Loss: Quantified Impact of Shape on Stone Utilization

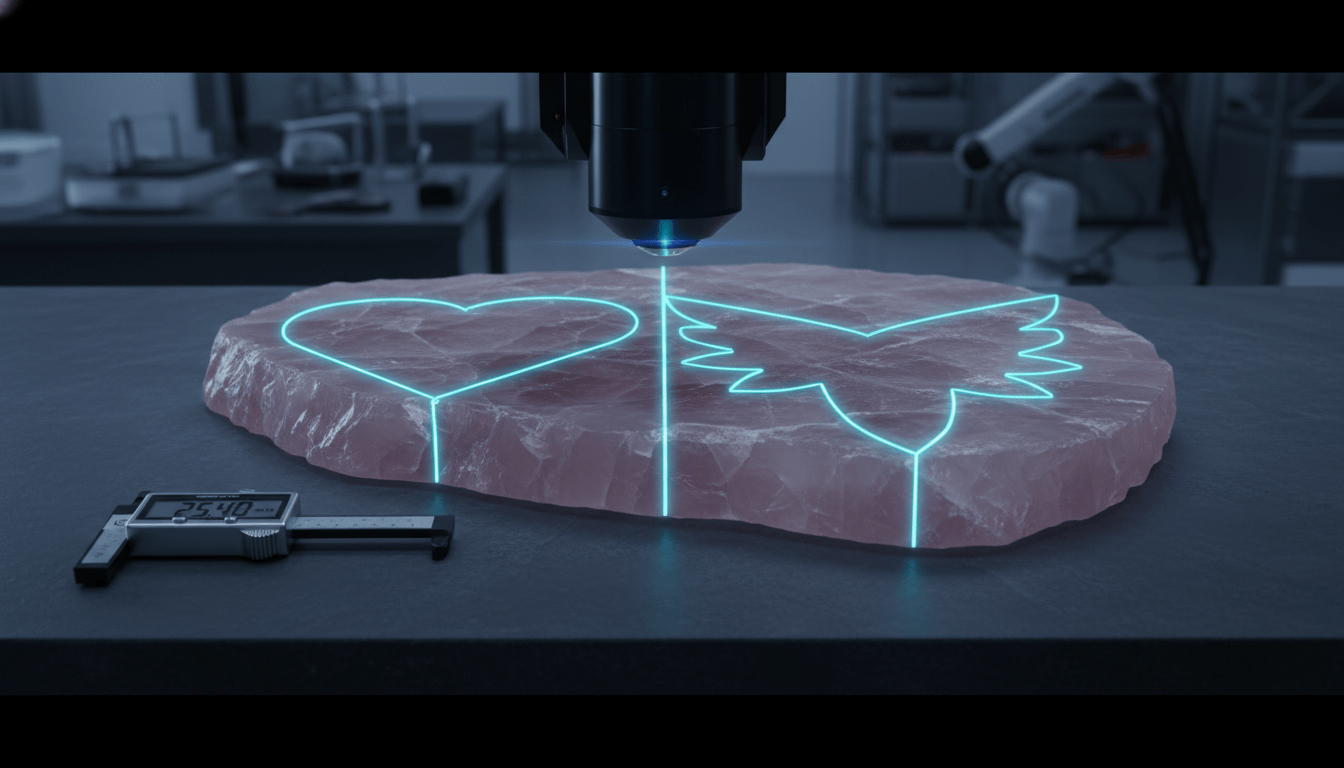

Measurement Method for Material Utilization Rate

Material utilization rate is defined as the ratio between the total net weight of finished gua sha tools and the gross weight of raw stone blocks used for the same production batch. Measurements are conducted using calibrated industrial digital scales with a resolution of ±0.1 g.

Raw stone blocks are weighed before cutting, and finished tools are weighed after final inspection. All measurements are taken at batch level rather than on individual pieces to avoid sampling bias.

Shape-Dependent Utilization Results

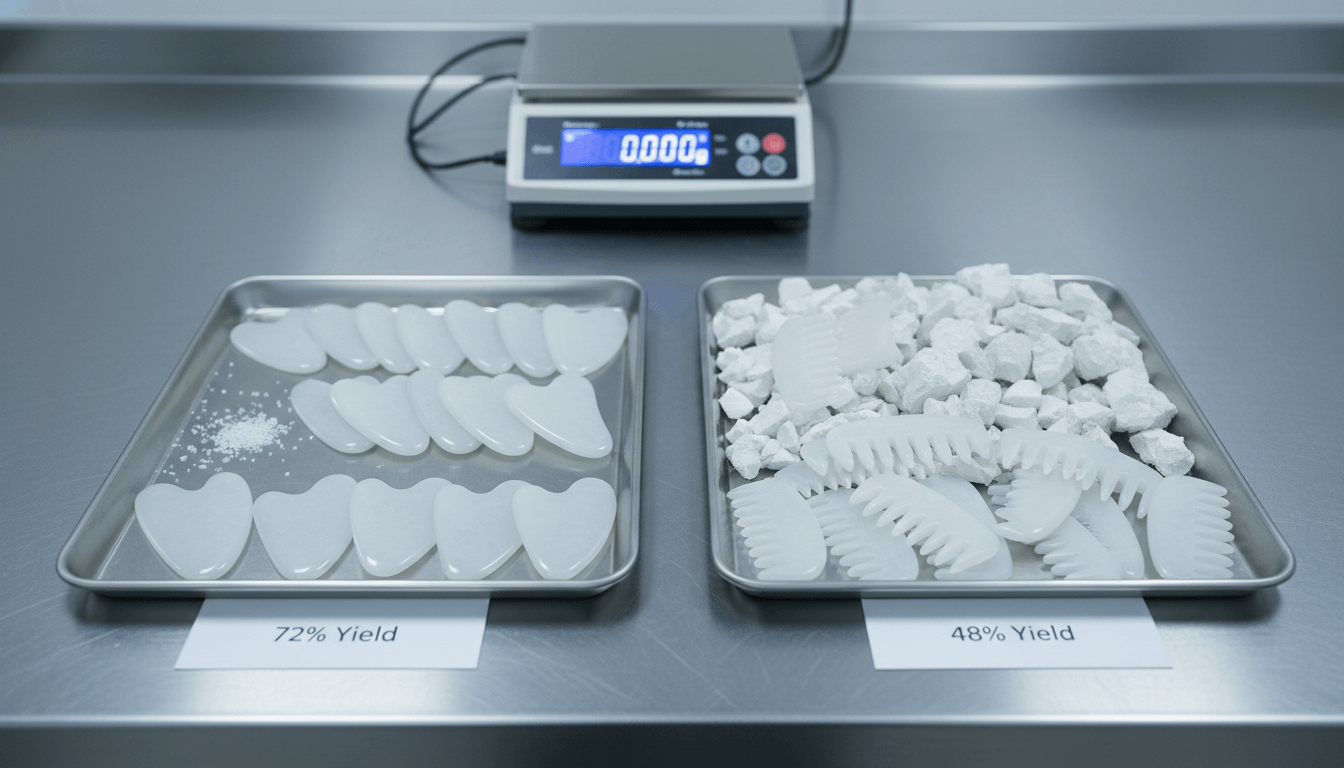

Based on aggregated production data, simple gua sha tool shapes such as half-moon or oval profiles typically achieve material utilization rates between 65% and 72%. These shapes allow efficient nesting during slab cutting and generate fewer unusable offcuts.

In contrast, comb-shaped gua sha tools with multiple narrow teeth generally show utilization rates between 48% and 55%. The increased number of cutting paths and thin edge structures leads to higher irreversible waste. Across commercial-scale production, this difference translates directly into higher raw material cost per unit.

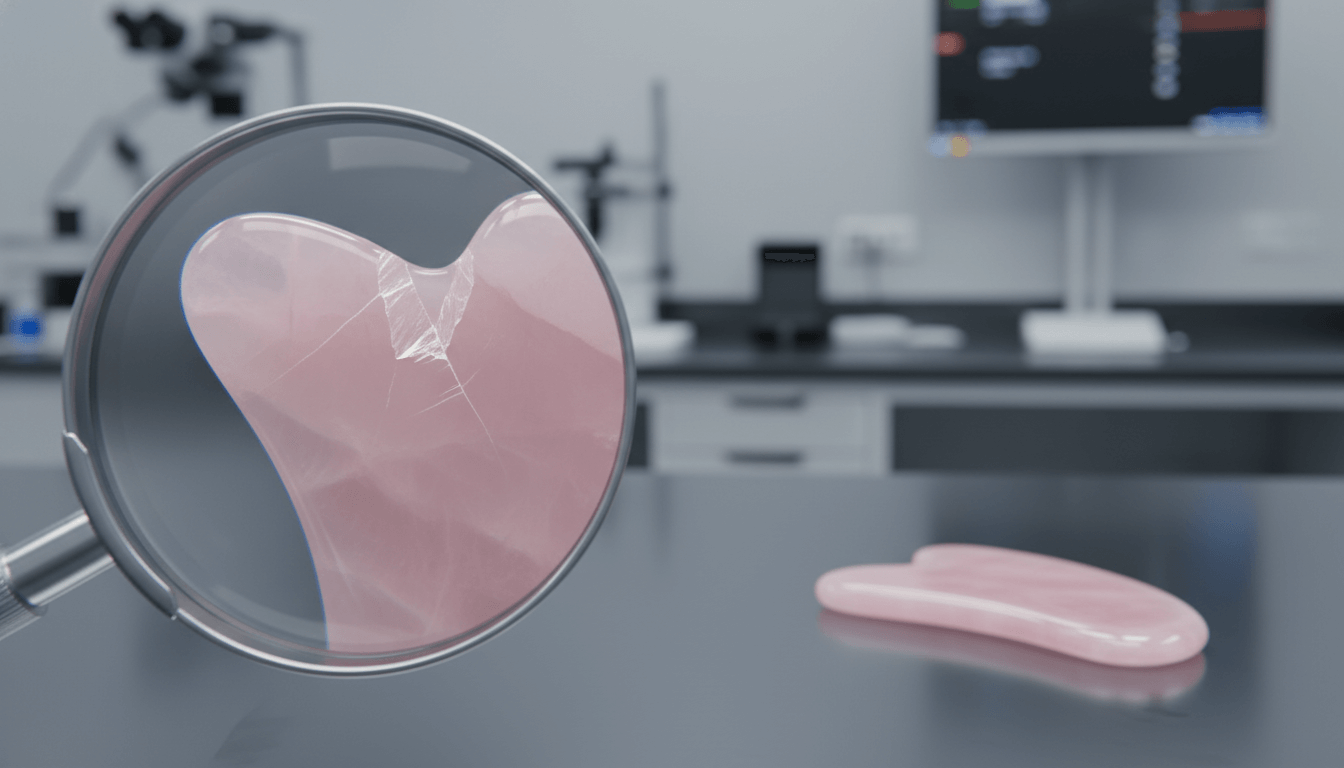

Finished Yield Rate: Edge Geometry and Defect Probability

Inspection Method and Yield Definition

Finished yield rate represents the percentage of gua sha tools that pass final quality inspection without cracks, edge chipping, or surface defects. Inspection is conducted under neutral lighting conditions of approximately 500–1,000 lux, combined with tactile checks and 10× optical magnification for edge inspection.

Only tools meeting both visual and functional standards are classified as acceptable finished goods.

Yield Differences by Shape Complexity

For gua sha tools with smooth, continuous curves, finished yield rates typically fall within 92%–96% under stable production conditions. Stress is evenly distributed during polishing, reducing the likelihood of micro-fracture formation.

By contrast, shapes featuring thin edges, sharp angle transitions, or internal concave curves often exhibit yield rates of 78%–85%. These designs concentrate mechanical stress at specific points during grinding and polishing, increasing the probability of edge damage.

Production Time: Shape-Driven Differences in Manufacturing Cycle

Time Measurement Methodology

Unit production time is measured using process-level time tracking, recording active machine or manual processing time at each stage, including cutting, grinding, and polishing. Waiting, storage, and transport time are excluded to ensure consistency.

Time data is averaged across multiple production batches to reduce operator-specific variance.

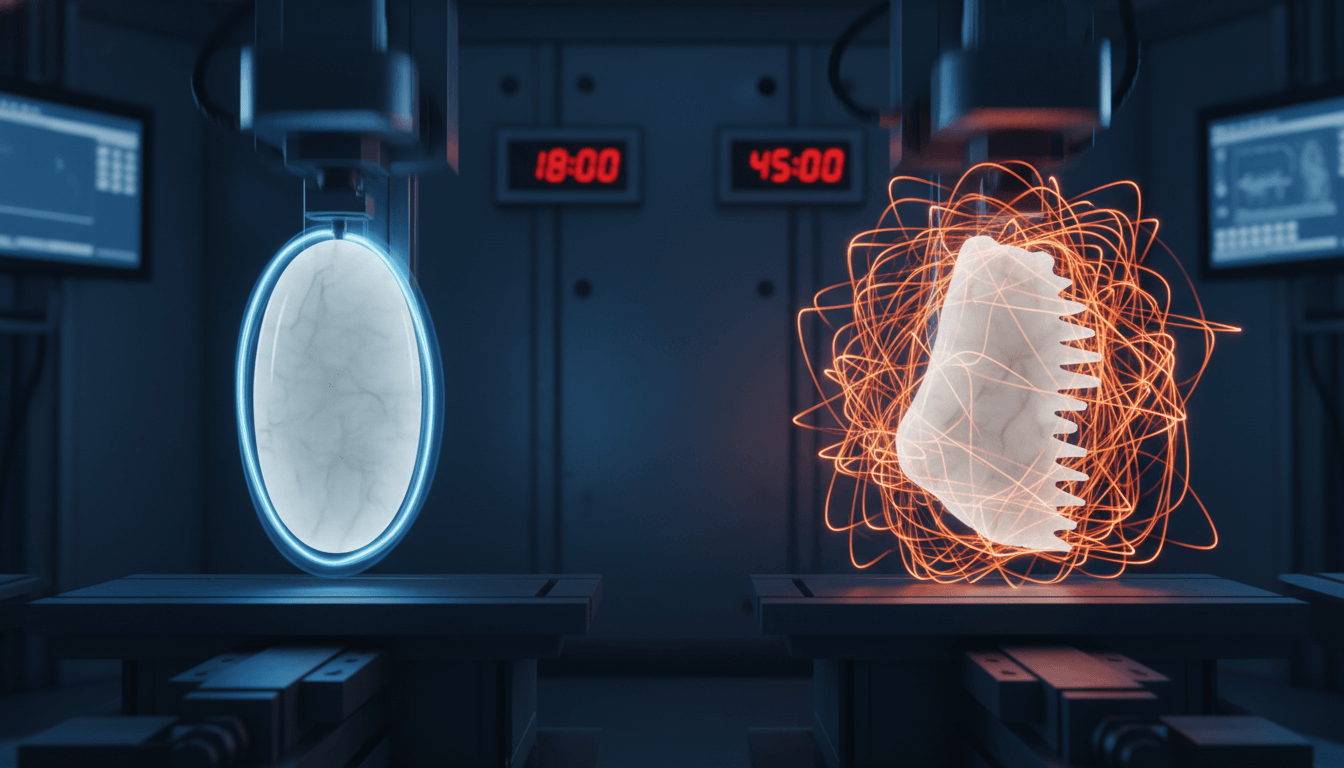

Comparative Production Time Ranges

Standard facial gua sha tool shapes generally require 18–25 minutes per unit from initial cutting to final polishing. These shapes support stable CNC paths and semi-automated polishing processes.

Complex gua sha tool shapes, such as comb-edge or multi-angle designs, often require 35–45 minutes per unit, representing a 40%–60% increase in total processing time. Additional time is primarily consumed by segmented polishing and reduced-speed cutting to protect thin edges.

Key Process Parameters Influenced by Gua Sha Tool Shape

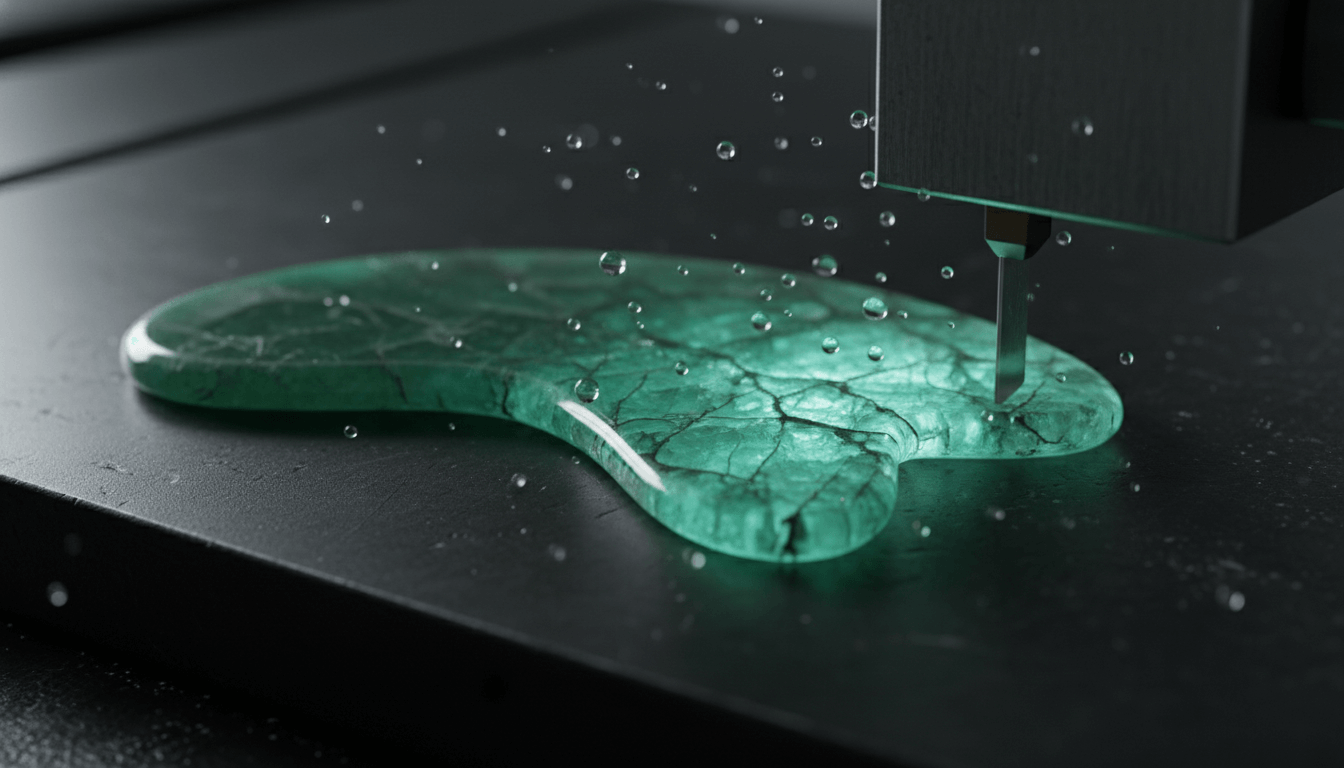

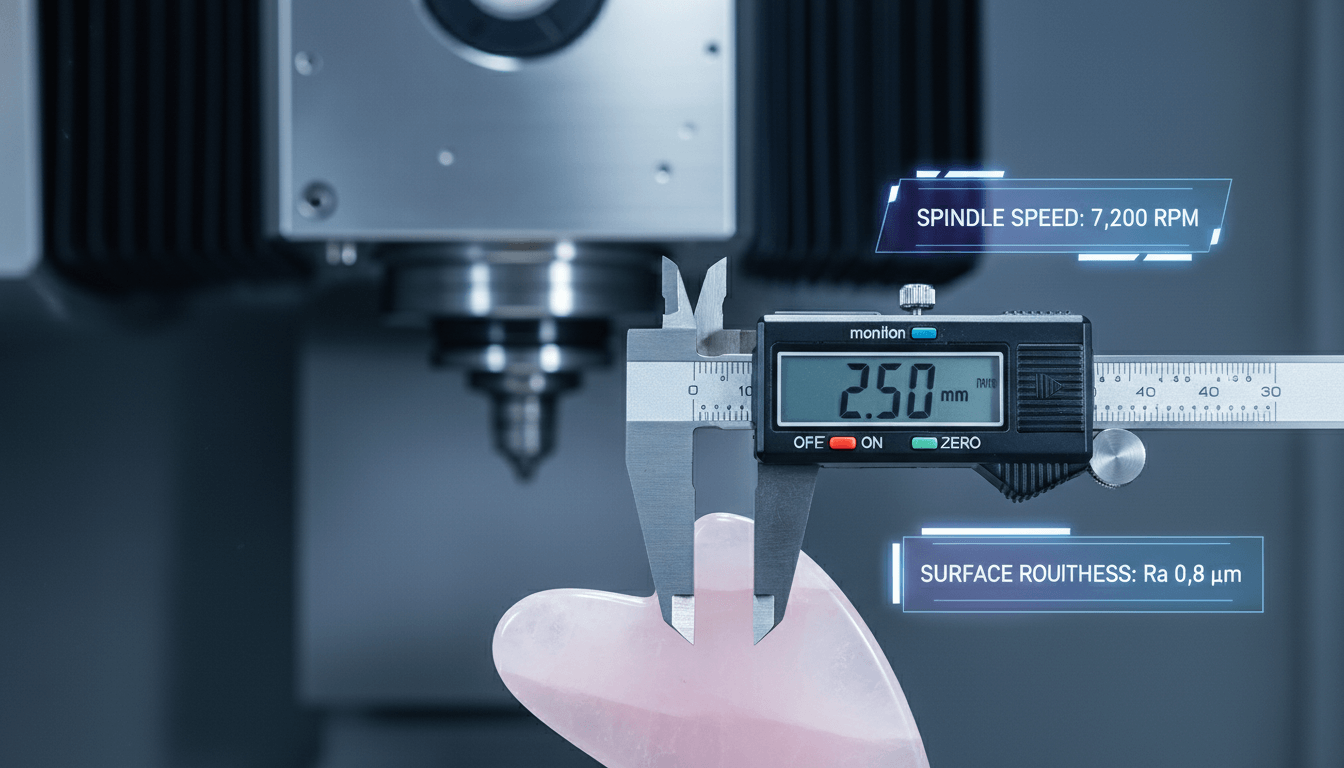

CNC Cutting Parameters

For simple shapes, CNC spindle speeds typically range from 8,000 to 12,000 RPM, allowing efficient material removal while maintaining structural stability. Feed rates are optimized for consistent cutting pressure.

For complex shapes with fine features, spindle speeds are commonly reduced to 6,000–8,000 RPM. This reduction minimizes vibration and lowers the risk of micro-cracking along thin edges.

Edge Thickness Control

Edge thickness is a critical control variable. In commercial facial gua sha production, minimum finished edge thickness is usually maintained between 2.2 and 2.8 mm. Designs requiring edge thickness below 2.0 mm demonstrate sharply increased breakage rates during polishing and post-production handling.

Polishing Pressure and Surface Finish

Polishing pressure and dwell time are adjusted based on curvature and edge geometry. Flat or convex surfaces tolerate uniform pressure, while fine edges require reduced force and segmented polishing. Final surface finish targets a surface roughness value below Ra 0.8 μm to ensure smooth skin contact.

Sample Size and Data Scope Disclosure

The quantitative ranges presented in this article are derived from aggregated data across 3–5 commercial production batches per shape category, with individual batch sizes ranging from 300 to 2,000 units.

In total, the analyzed dataset covers more than 8,000 finished gua sha tools manufactured from natural jade and quartz materials. The reported values represent stable commercial averages observed under controlled factory conditions, rather than experimental or prototype-level extremes.

These findings are intended to support OEM and ODM sourcing decisions rather than one-off custom production.

Manufacturing Standards and Verification Frameworks

Professional gua sha factories typically operate under ISO 9001 quality management systems, requiring documented control of process parameters, inspection methods, and corrective actions. Shape-related defect rates are monitored using statistical process control principles to identify recurring failure points.

Surface finishing benchmarks align with gemstone and jewelry industry polishing guidelines commonly referenced by international gemological organizations. For export markets, material safety is evaluated against regulatory frameworks such as EU REACH and California Proposition 65, particularly for dyed or treated stones.

Cost Range and MOQ Comparison by Gua Sha Tool Shape

Simple gua sha tool shapes fall within a low-to-mid production cost range and typically support minimum order quantities of 300–500 units per design. These shapes offer stable yield rates and predictable delivery timelines.

Moderately complex shapes, including heart and wave profiles, occupy a mid-range cost tier. Recommended MOQs generally range from 500–1,000 units, balancing setup efficiency and defect risk.

Highly complex shapes such as comb-edge or multi-surface designs represent the high-cost tier. Due to lower yield rates and extended processing time, factories often require MOQs of 1,000–2,000 units or more to maintain production stability.

Conclusion: Shape as a Verifiable Manufacturing Decision

In gua sha production, tool shape is a primary determinant of material efficiency, yield stability, production time, and cost structure. When evaluated using defined measurement methods, sufficient sample sizes, and recognized manufacturing frameworks, shape becomes a quantifiable production variable rather than a subjective design choice.

At Deyi Gems, we believe successful gua sha tools are those developed with both consumer experience and factory reality in mind. Aligning design ambition with verifiable production logic ensures long-term quality, scalability, and supply reliability.