Gua sha, a traditional Chinese medical practice, is currently undergoing transformation and expansion. It’s no longer confined to a domestic treatment method but has become a global daily skincare tool. With market expansion, major skincare companies are turning their attention to gua sha. In the past, gua sha tools made of jade, crystal, and buffalo horn dominated the market, creating a monopoly. However, the emergence of stainless steel gua sha tools has quickly broken this pattern. The market share of stainless steel gua sha tools is steadily increasing, and major skincare brands are starting to wholesale stainless steel gua sha tools to supplement their product lines.

This guide aims to provide some guidance for brands or store owners planning to source stainless steel gua sha tools. We will delve into three aspects: material identification, quality control factors, and communication skills with gua sha suppliers. This will help you handle gua sha procurement efficiently and professionally.

Stainless Steel Gua Sha Wholesale – Material Explanation

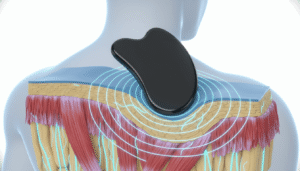

The rise of stainless steel gua sha is not accidental; an analysis of its material reveals its inevitability. This stems from the unparalleled durability, professionalism, user experience, and aesthetics of stainless steel. These four factors collectively guided the market’s choice of stainless steel gua sha.

Amazing Durability

Stainless steel is extremely durable. Through the fusion of various metals and other elements, stainless steel retains the high ductility of metals while also possessing considerable strength. Compared to gua sha tools made of crystal or stone, stainless steel gua sha tools undoubtedly offer superior durability.

Why are stainless steel gua sha tools so durable?

- Drop-resistant: While crystal/stone gua sha tools are very hard, they lack ductility, making them highly likely to shatter upon impact with a drop. Stainless steel gua sha tools, on the other hand, typically only experience slight deformation, which does not affect normal use.

- High-temperature resistant: Many crystals and stones, due to their natural internal patterns, may change or be damaged when exposed to high temperatures. Furthermore, for crystals like rose quartz, high temperatures may cause color fading. Therefore, we do not recommend high-temperature sterilization of crystal/stone gua sha tools. Stainless steel gua sha tools, however, do not have this problem.

- Corrosion Resistance: Stainless steel, as its name suggests, is designed to resist rust. Therefore, any high-quality stainless steel should possess extremely high rust resistance. This is especially true for 316 stainless steel, whose performance is further enhanced.

- Low wear and tear: Some gua sha tools, such as those made of resin or buffalo horn, will experience wear and tear after a period of use, such as thinning and changing shape. However, stainless steel gua sha tools do not have this problem. Contact with soft tissues like skin will not cause stainless steel to wear down.

The durability of stainless steel gua sha tools stems from their inherent superior properties. They perfectly overcome some of the disadvantages of crystal/stone materials.

Higher Professionalism

Stainless steel is widely used in the food and medical fields due to its excellent properties. Therefore, it should be considered a top-tier material for professional beauty and skincare tools. It has the following advantages:

- Safety. As mentioned earlier, stainless steel is not easily broken, so the probability of skin injury due to damage to the gua sha tool during use is extremely low.

- Easy to disinfect and meets high hygiene standards: Stainless steel itself has antibacterial properties, and its smooth, non-porous surface prevents the absorption or growth of bacteria. Furthermore, stainless steel is extremely easy to clean, fully meeting high hygiene standards.

- Specialization: Due to its ductility, stainless steel is easy to process. Therefore, it’s easier to work with than materials like crystal or stone when making gua sha tools that require precise design for specific functions. Thus, stainless steel has an advantage in crafting professional gua sha tools.

Excellent Experience

Crystal/stone materials are highly praised for their excellent user experience. Their natural cooling sensation and smooth touch create a relaxing feeling. However, stainless steel gua sha tools offer a comparable experience to crystal/stone materials.

- Low temperature, calming and soothing: Stainless steel, as a metal material, has excellent thermal conductivity. Before use, it can be refrigerated for 10-15 minutes to provide a cooling sensation during gua sha. This low-temperature cooling can help relieve fatigue and tension, reduce facial swelling, and soothe the skin.

- Excellent feel: Stainless steel has a uniform weight distribution, and thanks to its ease of processing, enhancing ergonomics in tool design is much simpler than with materials like crystal. This advantage allows users to better control the force and angle during operation, applying stable and even pressure, thereby improving the accuracy and effectiveness of gua sha and delivering a more professional beauty experience.

Aesthetics

Beauty is subjective; different people may have different preferences. However, it’s undeniable that beauty tends to converge. Most people’s views on beauty are largely similar, with only minor differences in preference.

The beauty of stainless steel differs from the natural, luxurious feel of crystal and other materials. It’s a modern, high-end industrial beauty, a futuristic mechanical beauty. This is precisely the aesthetic sought after by modern young people, helping to enhance brand image.

Besides its inherent beauty, stainless steel is recyclable. Discarded stainless steel gua sha tools can be recycled, melted, refined, and reprocessed into new products, making it a recyclable resource that satisfies today’s consumer preference for sustainable consumption.

Based on the inherent characteristics of the material, stainless steel gua sha tools have a unique advantage over crystal/stone gua sha tools in terms of durability and professionalism, while also being equally appealing in terms of user experience and aesthetics. Excluding the potential “stone energy” factor, stainless steel gua sha tools should be a superior choice.

Important Considerations for Stainless Steel Gua Sha Wholesale Purchasing: Material, Quality Control, and Packaging.

In the procurement process of stainless steel gua sha, understanding the characteristics of the material is only a necessary preparation before the transaction. More importantly, it is about ensuring the safety, consistency, and stability of the product.

Stainless Steel Material Identification and Selection

Currently, the stainless steel gua sha tools on the market mainly come in two types: 304 and 316 stainless steel. These two types of stainless steel are indistinguishable in appearance. How to choose?

- 304 Stainless Steel: The most common food-grade stainless steel. It’s widely used in food utensils, such as the inner walls of insulated cups, stainless steel bowls, and chopsticks. It boasts excellent corrosion resistance and strength, making it a mainstream choice in the market.

- 316 Stainless Steel: Medical-grade stainless steel. Compared to 304, it has higher standards and performance, with further improvements in safety and corrosion resistance. Currently, with people’s pursuit of higher safety and quality of life, 316 stainless steel is becoming increasingly common in the mass market.

Both 304 and 316 are excellent stainless steel materials, and both offer guaranteed safety. Therefore, the choice between these two materials depends on your actual needs. Just remember: 316 stainless steel gua sha tools are always more expensive than 304 stainless steel gua sha tools; this is determined by the material’s inherent price.

The most dangerous things to be wary of are counterfeit products that masquerade as stainless steel. The most common method is to choose ordinary metal and then coat it with a silver-gray, rust-resistant electroplating layer to imitate stainless steel. This is very difficult to distinguish with the naked eye.

Stainless steel material identification techniques:

- Certificate Verification: The most direct and reliable method of identification. Verify the precise chemical composition and type of stainless steel through material testing reports from professional institutions provided by the supplier. If necessary, request international standard certifications such as RoHS and REACH.

- Magnetic Test: 304/316 stainless steel gua sha tools are typically non-magnetic or only slightly magnetic, meaning magnets cannot directly adhere to them. This can be used to test for counterfeit products that use ordinary metals to imitate stainless steel, but it is not an absolute standard and should be used as a reference.

Stainless Steel Gua Sha Quality Standards

The quality of stainless steel gua sha tools should be judged from two main aspects: the stainless steel material itself and the requirements for use as a gua sha tool. Only when both meet the standards can it be considered a qualified stainless steel gua sha product:

- The surface should be smooth and mirror-like, without obvious brushing, scratches, or color differences. This relates to the quality of the stainless steel itself and the level of processing. Brushing on the surface indicates poor polishing, reflecting insufficient processing capabilities in the factory. Scratches may be caused by improper storage, affecting the normal use of the gua sha tool. Color differences may indicate low-quality stainless steel or even counterfeit products.

- The edges should be rounded and smooth. This is crucial for the safety of the gua sha board. All edges and chamfers used for gua sha must be finely polished to achieve a smooth, rounded finish, without any burrs or sharp edges, otherwise, they may damage the skin.

Stainless steel Gua Sha Packaging Requirements

Stainless steel has excellent ductility and malleability, but this also means that its hardness is not very high. Furthermore, the high quality requirements of mirror polishing can lead to scratches, so careful attention must be paid to packaging choices:

- Scratch Prevention: Ensure each stainless steel gua sha tool has an individual protective layer, such as bubble wrap or a velvet bag. This prevents scratches caused by impacts or friction with hard objects during transportation or packaging.

- Collision Prevention: Collisions between stainless steel parts can also cause damage. Therefore, the transport packaging should be secure to prevent collisions caused by excess space.

- The packaging should not contain substances harder than stainless steel to avoid scratching the surface.

Communication Skills with Stainless Steel Gua Sha Supplier

Effective communication can not only accelerate your procurement process but also potentially create higher profit margins. How to communicate with stainless steel gua sha suppliers? Keep the following key requirements in mind:

1. Define the Requirements

Clearly defining requirements is key to accelerating the entire procurement process. These requirements apply not only to you but also to the suppliers themselves, and can be summarized around several points:

- Minimum Order Quantity (MOQ): Thoroughly understand the minimum order quantity for different materials, colors, and customization options. Knowing the supplier’s MOQ will help you plan your inventory and calculate costs. Different suppliers have different MOQ requirements, which is one of the criteria for selecting a stainless steel gua sha wholesale supplier.

- Specification Confirmation: If you have your own product design, be sure to provide accurate drawings and dimensional requirements. This will help the stainless steel manufacturer calculate the expected price and sample production, etc.

- Quality Requirements: Different manufacturers may have different quality standards, so you need to clarify your quality standards. For example, polishing standards, dimensional tolerances, and yield rates, etc., to avoid losses due to quality discrepancies. You can request samples from the stainless steel gua sha manufacturer before production to confirm quality standards.

- Delivery Time Requirements: Clarify the delivery time. Late delivery may adversely affect your sales plans.。

2. Qualification Requirements

- Product Certification: Some countries and regions may require specific product certification information for product sales, such as the CE certification required by the European Union. Suppliers should be required to provide certifications specific to their region, or be asked whether product certification testing is available.

- Factory Audit: If your procurement volume is large, for security reasons, you should request a third-party factory audit to assess its qualifications and capabilities, thereby protecting your interests. This mainly includes its production capacity, equipment level, quality control processes, and even employee benefits.

3. Rational negotiation

Negotiation is an essential process, as lower costs translate to higher profits, especially for large orders. However, negotiation should be measured; blindly pushing for lower prices is unwise. If a supplier accepts a price significantly below market value, they may compromise on quality.

You can persuade suppliers to accept your price negotiation by expressing a desire for long-term cooperation. This usually secures better product prices, more flexible payment options, and priority in production.

Don’t be aggressive when communicating with suppliers; this won’t benefit your order and may even hinder your procurement process.

Stainless Steel Gua Sha Wholesale Guide Faqs

1. Is Using A Magnet to Identify A Stainless Steel Gua Sha Tool Always Accurate

This information is not entirely accurate and should only be used as a reference. While stainless steel is generally non-magnetic, some other metals do possess this property. Furthermore, even using a magnet to test the stainless steel will not allow you to distinguish it as 304, 316, or any other type. The most accurate way is to confirm the product testing and certification information provided by the supplier.

2. Will Stainless Steel Never Rust

Although stainless steel has extremely high corrosion resistance, it is not absolutely rust-proof. Prolonged contact with water and exposure to air will significantly reduce its rust resistance, leading to rust formation. Therefore, stainless steel gua sha tools should be stored in a dry environmen.

3. Can A Stainless Steel Gua Sha Tool Still be Used If It Has Scratches

It depends on the location of the scratch. Since the tool contacts the skin at the edge during gua sha, scratches on the sides of a stainless steel gua sha tool won’t affect its use. However, if the scratch is on the edge, it may cause skin damage during use, in which case continued use is not recommended.