In our article, “The Complete Guide to Custom Gua Sha Tools – Insights from a Gua Sha Factory” we detailed the entire Gua Sha customization process, including market research, customization standards, payment terms, and shipping methods. However, there are still many details that can be added.

This article will focus on explaining the logo customization aspect of Gua Sha tools. Through this information, you will gain a better understanding of Gua Sha customization and be able to make more informed choices for your order.

1. Detailed Explanation of the Custom Gua Sha Logo Technology

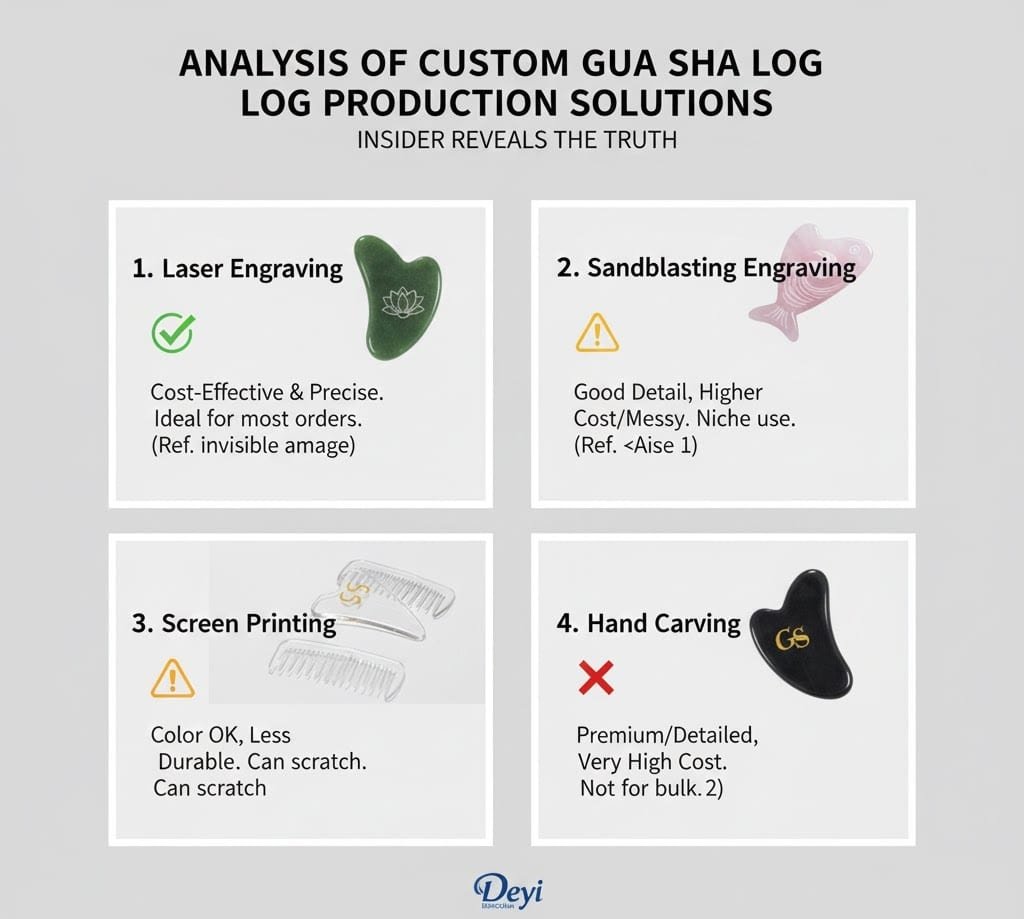

Customizing a Gua Sha logo is the most cost-effective option among Gua Sha customization solutions, offering low pricing and small minimum order quantities. However, there is more than one way to produce a Gua Sha logo, and each method comes with its own advantages and limitations. Today, we have selected four of the most representative logo production methods for your reference.

1.1 Laser Engraving

This is the most commonly used logo production method for Gua Sha custom orders. It works by directing a high–energy–density laser beam onto specific areas of a material’s surface. When the surface is exposed to the laser, a series of changes occur—such as vaporization, carbonization, or other physical and chemical reactions—leaving a precise pattern on the surface. When applied to Gua Sha tools, this process creates permanent engraved indentations.

Materials suitable for laser engraving include natural materials, plastics, metals, coated metals, as well as stone and glass.

Source of laser-engraving materials: Wikipedia – Laser engraving

Advantage:

- High precision: The laser beam is extremely fine, allowing for very detailed lines and complex designs.

- Fast processing: Engraving a single logo usually takes only 1–3 seconds.

- Wide material compatibility: Suitable for a variety of materials, including metal, stone, and ceramic.

- Controllable results: The depth of the logo can be adjusted as needed, offering high flexibility.

- Low cost: Typically priced at under USD 0.50 per unit.

Disadvantage:

- Certain heat-absorbing or highly reflective materials are not suitable for laser engraving.

- If a colored logo is required, manual painting is necessary, which may result in paint residue on the product surface.

- The engraved logo surface may have a slight grainy texture and cannot be made completely smooth.

Insider Tips:

Laser engraving is the most widely used logo production method in the Gua Sha industry, accounting for over 80% of our total orders. Its key advantages are low cost and low minimum order quantities, making it suitable for both large brands and small buyers. However, because different materials can produce different final results, we strongly recommend obtaining a physical sample before placing a formal order

1.2 Sandblasting Engraving

This method works by using compressed air to propel abrasive particles at high speed onto the surface of an object, creating indentations or a matte, frosted effect through surface impact. There are many types of sandblasting, and the technique used for Gua Sha logo engraving falls under micro-sandblasting.

Source: Wikipedia – Micro sandblasting

Advantages:

- Lower cost than laser engraving.

- Better suited for large-area processing: Ideal for engraving larger logos compared to laser engraving.

- Stronger depth and texture: The matte, sandblasted surface appears more natural and offers a more tactile finish.

Disadvantages:

- Lower precision than laser engraving: Less capable of handling fine details.

- High environmental requirements: The process generates dust, requiring enclosed workspaces and proper dust-collection systems.

- Manual painting required: This can easily lead to paint residue on the Gua Sha surface.

- Limited material compatibility: Suitable mainly for hard materials such as metal, stone, and glass, but less effective on softer materials like wood.

Insider Tips:

Sandblasting is generally not used for engraving logos on Gua Sha tools, for several reasons:

- Precision limitations: Gua Sha tools are relatively small, and the logos on their surfaces are usually small as well, requiring a high level of detail. Sandblasting often cannot meet these precision requirements.

- Potential scratching issues: Gua Sha tools typically require a smooth surface finish. During sandblasting, fine abrasive particles can scatter around the logo area. Without proper protection, this may cause scratches around the logo, negatively affecting the final product quality.

- Cost at low volumes: For small order quantities, sandblasting offers no clear cost advantage over laser engraving and may even be more expensive.

1.3 Screen Printing

Screen printing has a long history, originating from Chinese woodblock printing. It was introduced to the West around the 1770s and gradually gained widespread acceptance and use.

The technical principle of screen printing involves transferring ink or paint onto a substrate through a mesh screen. The screen blocks ink in non-logo areas, while the logo area is designed as a stencil to allow ink passage. Ink is applied onto the screen, and a squeegee is used to move the ink across it. The ink passes through the open areas of the stencil onto the substrate, leaving the desired design.

Source: Wikipedia – Screen printing

Advantages:

- Wide substrate compatibility: Suitable for a variety of materials, with minimal restrictions on size or shape, and can even print on curved or irregular surfaces.

- Cost-effective for large batches: The per-unit printing cost is low when producing in bulk.

- Fast printing speed: Once the stencil is set up, multiple small items can be printed simultaneously.

Disadvantages:

- Not suitable for small orders: The cost of creating the stencil makes the average per-unit cost higher for low-quantity orders.

- Color limitations: Only single-color printing is possible at a time. Multi-color logos require additional steps and stencil costs.

- Substrate requirements: Printing quality suffers on rough or uneven surfaces.

- Lower precision: Due to the nature of the printing process, controlling ink volume and thickness is difficult, which can result in color inconsistencies or incomplete prints.

Insider Tips:

For Gua Sha products, we rarely use screen printing on the tools themselves unless specifically requested by the customer. In addition to the issues mentioned above, such as minimum order quantity and precision, another reason is related to the nature of the tools.

During use, Gua Sha tools inevitably come into contact with the logo area. Over time, the ink applied to the tool may wear off, resulting in logo damage. Therefore, screen printing is more commonly used on product packaging or gift boxes rather than on the tools themselves.

1.4 Hand Carving

Hand carving involves using a craft knife to engrave patterns or text onto the surface of a product. This method is commonly seen in the creation of seals and stamps. Hand carving has a long history and is applied across a wide range of industries.

Advantages:

- Uniqueness: Hand-carved logos are typically produced entirely or partially by hand, so each logo has subtle differences, making it truly one-of-a-kind.

- Cultural value: A hand-carved logo embodies the spirit of craftsmanship—it is more than just a logo; it represents the “soul” of the artisan who created it.

Disadvantages:

- High cost: Hand-carved logos are significantly more expensive than other production methods, with prices varying based on the skill level of the artisan.

- Slow production: Engraving a logo by hand, stroke by stroke, is much slower than other methods.

- Limited availability: Not all factories offer hand-carving services for logos.

Insider Tips:

Hand-carved logos are not suitable for large-scale Gua Sha production. They are better suited for niche audiences who value cultural significance and uniqueness. Alternatively, you can leverage the distinctiveness of a hand-carved logo to create a truly one-of-a-kind gift for someone special in your life, such as your mother or partner.

In addition to the four logo production methods mentioned above, there are several other techniques available, including:

- Pad printing

- Heat transfer

- Foil stamping (gold/silver)

- Branding (burning)

- Stamping/embossing

- Film or sticker application

- …

Considering that the logo production methods listed above are rarely used in the Gua Sha industry, we will not provide detailed introductions. Unless specifically requested by a customer, these methods are not our primary options.

Insider Tips:Our primary recommendation for creating your logo is laser engraving. For Gua Sha products, laser engraving is the most balanced and effective logo production method. Its key advantages are:

- Low cost: Unit cost does not exceed USD 0.50.

- Low minimum order quantity: Only 50 pieces required.

- High-quality results: Offers high precision, and the logo is resistant to wear.

2. How to Determine if a Custom Gua Sha Logo Meets Quality Standards

The quality of a custom Gua Sha logo should be evaluated from multiple dimensions, and the criteria may vary depending on the production method. Common aspects to consider include:

- Color consistency: Check for any color deviations.

- Dimensions: Verify that the logo size matches the specifications.

- Position and angle: Ensure the logo is correctly placed and aligned.

- Edge details: Examine the edges for smoothness and precision.

For specific production methods, additional factors may also be relevant, such as the thickness and adhesion of the ink.

2.1 Custom Gua Sha Logo Color Difference Standards

2.1.1 Color Difference Standard

Our factory uses the internationally recognized ΔE (Delta E) metric to evaluate whether a logo’s color deviation meets quality standards.

- What is ΔE (Delta E)? It is a standard unit for measuring the difference between two perceived colors. The lower the value, the more similar the colors are. A ΔE below 1.0 is generally imperceptible to the human eye, while a ΔE above 3.0 is easily noticeable.

Source: ViewSonic – Delta E ≦2 Color Accuracy - Importance: Color consistency is crucial as it plays a key role in brand perception. If the logo on a product shows significant color deviation, consumers may perceive the brand’s product quality as inferior.

To ensure consistent logo color on Gua Sha tools, we adhere to a standard of ΔE ≤ 3, meaning that any color difference is imperceptible to the naked eye.

2.1.2 Color Codes & Pre-Production Samples

In addition to checking color deviation after production, another crucial step in ensuring the accuracy of a Gua Sha logo’s color is confirming a pre-production sample. We’ve observed two common issues in this process:

- No precise color code provided:

Clients often do not provide an exact color code and may only give a vague color description, such as “gold” or “gray.” Such ambiguous descriptions can lead to significant color variation, causing the final product to differ from expectations. - Non-Pantone color codes:

Even when a color code is provided, it is often based on display colors (e.g., RGB) rather than Pantone colors, which are a physical, standardized system. RGB colors can vary depending on screen quality. The same color may appear darker or lighter on different screens, leading to discrepancies between the expected and final product colors.

Pantone colors, on the other hand, are pre-mixed inks and provide the most reliable printing results. They ensure consistent brand colors across packaging, printed materials, websites, and product manufacturing.

Source: learn.g2.com – What Is Pantone?

Insider Tips:

To prevent the color deviation issues mentioned above, you can take the following two measures:

- Provide a standard Pantone color code.

- Request a pre-production sample to verify the logo color. Even if you do not have an exact Pantone code, confirming the color on a sample allows you to establish the expected logo color standard.

Typically, significant color deviations are rare within the same order and are more common in reorder scenarios. Therefore, for reorders, it is especially important to pay attention to logo color consistency. We recommend keeping a sample for reference in future orders. (Make sure to store it properly, as the color of the logo may change over time, which could affect your judgment.)

2.2 Standard Dimensions for Custom Gua Sha Logo.

A logo should have a precise size standard, just like the product itself. Inconsistent logo dimensions not only affect the overall aesthetics but can also negatively impact brand image.

Excluding hand-carving and other uncontrollable production methods, all other logo production techniques should adhere to strict size standards. Since the vast majority of these methods are fully automated and machine-based, there should be no visible size discrepancies to the naked eye.

- Tolerance differences among factories: Different factories may follow different tolerance ranges for logos. Our factory maintains a strict tolerance of ≤0.1 mm, meaning the difference between the final product and the sample will not exceed 0.1 mm.

- Occurrence: Within a single order, inconsistent logo sizes are extremely rare and are more likely to appear in reorder scenarios.

Insider Tip:

Although the likelihood of logo size discrepancies is low, it is still important to remain vigilant—especially for reorder scenarios. Long gaps between orders may cause the supplier to lose data from the first order, increasing the risk of size errors in subsequent orders. We recommend keeping a sample from the first order for comparison purposes.

2.3 Standard Specifications for Custom Gua Sha Logo Placement

Compared to issues with the size of the gua sha logo, incorrect logo placement is more likely to occur. This is due to two main reasons:

- The inconsistency in the shape of gua sha tools. This is especially common with gua sha tools made of materials such as crystal or stone. Due to the natural materials and semi-manual manufacturing process, there are certain variations in the shape of individual crystal/stone gua sha tools; they are not completely uniform.

- The irregular shape of gua sha tools. Most gua sha tools are irregularly shaped. They may not be symmetrical vertically or horizontally.

These two reasons make it difficult to determine a specific coordinate system for logo placement during the manufacturing process. The placement largely depends on the experience of the processing personnel. For experienced factories, they may set certain reference coordinates based on a specific characteristic of the gua sha tool. The following are our factory’s standards for your reference:

- Logo position: The horizontal and vertical deviation from the standard sample should not exceed 1 mm.

- Logo angle: The difference in angle compared to the standard sample should not exceed 1°.

Insider Tips:

For any order, you should request that the supplier provide precise position tolerance data and a standard sample for reference. If the supplier cannot provide specific data or a sample, you should exercise caution when doing business with them.

2.4 Logo Edge Detail Standards

Any logo manufacturing process has the potential for defects, and the probability of defects occurring under the same process varies depending on the material. For natural stone materials, due to their inherent characteristics (high hardness but brittleness), the probability of defects appearing at the edges is higher.

Detail considerations:

- Edge quality: Pay attention to the edges, checking whether lines are continuous and complete, especially for logos with intricate designs or fine lines, which are prone to defects.

- Overall logo integrity and surrounding cleanliness: For laser-engraved or sandblasted logos, edges may have leftover paint or minor scratches on the Gua Sha tool. For film-applied logos, check for signs of curling or lifting at the edges.

Insider Tips:

When inspecting a logo, in addition to visual checks, lightly rub the logo with your finger to see if any color fades or paint peels. It is recommended to choose laser engraving or sandblasting, as these methods greatly reduce the risk of color fading or paint peeling.

3. Final List of Custom Gua Sha Logo

Customizing a Gua Sha logo may seem complicated, but it’s actually straightforward if you focus on the key points. By keeping these in mind, you can confidently make decisions while avoiding potential risks:

- Standard logo customization: Laser engraving should be your first choice, as it offers the best balance of cost and quality.

- Premium logo customization: Hand carving is an option for high-end, niche orders, but it is not suitable for large-scale production.

- Logo color accuracy: Follow a ΔE ≤ 3 standard (or higher) to ensure consistent logo colors.

- Pre-production color confirmation: Provide a Pantone color code or request a pre-production logo sample to avoid discrepancies between the finished product and expectations.

- Logo size tolerance: Maintain a standard of ±0.1 mm to ensure uniformity.

- Logo position tolerance: Keep horizontal and vertical deviations within ±1 mm, and angle differences within 1°.

- Edge and detail quality: Ensure logo edges are free from defects and the surrounding area is clean, without paint residue or scratches.

When negotiating logos with your Gua Sha supplier, addressing these details will help you avoid hidden risks. If you still have concerns or want to save time, you can choose Deyi. With Deyi’s one-stop Gua Sha logo customization solution, you can achieve results that meet—or even exceed—all of the standards above.

4. Customized Gua Sha Logo Faqs

1. Is the MOQ for Custom Gua Sha Logos Very High?

The minimum order quantity (MOQ) for a Gua Sha logo depends on the production method chosen. For standard laser engraving, the MOQ is usually low, typically around 50 pieces. For certain specialized logo methods, such as screen printing or sandblasting, the MOQ may be higher.

2. How Many Colors Can I Choose For Custom Gua Sha Logo?

By default, Gua Sha logos are single-color. If a customer requests a multi-color logo, it is possible to upgrade for an additional fee. However, multi-color logos come with specific design requirements: there must be a clear separation between the colors.

In continuous patterns or text, overlapping inks or pigments can interfere with each other, causing color inconsistencies. Additionally, maintaining consistent color proportions across multiple Gua Sha tools is challenging, which can result in noticeable color variations between logos on different pieces.

3. Why is It Not Recommended to Use Stickers to Create Gua Sha Logo?

Although sticker logos are low in cost, they are not suitable for Gua Sha tools due to several factors:

- Material issues: Natural stone and crystal surfaces often have tiny, barely visible pores, which can prevent stickers from adhering securely.

- Usage concerns: During use, fingers frequently come into contact with the logo area. Over time, repeated touching and friction can cause stickers to peel, lift, or fall off.

For these reasons, we do not recommend using stickers for Gua Sha logo customization unless specifically requested by the customer.

4. Why is Hand-Carved Logo Design so Expensive?

Hand-carved logos are expensive primarily due to the labor-intensive and skill-dependent nature of the process:

- Skilled craftsmanship required: Each logo is created manually by an artisan, and the cost reflects their expertise and time.

- Time-consuming production: Carving a logo by hand, stroke by stroke, takes significantly longer than automated methods.

- Low scalability: Hand carving is not suited for large-scale production, so costs cannot be spread over many units.

- Uniqueness and cultural value: Each hand-carved logo is one-of-a-kind, adding intrinsic value that automated methods cannot replicate.

In short, the combination of high labor, long production time, and limited output makes hand-carved logos costly.