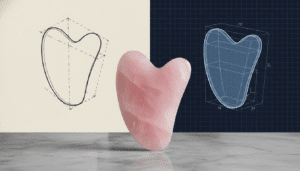

Gua sha tools have become essential instruments in modern wellness and beauty routines, widely appreciated for their ability to stimulate circulation, relax facial muscles, and enhance skincare absorption. But behind every beautifully polished gua sha tool lies a surprisingly meticulous production process—one that combines geology, hand craftsmanship, and precise mechanical engineering.

At Deyi Gems, a manufacturer specializing in premium gua sha tools, face rollers, and custom-crafted crystal products, we know that the quality of a gua sha tool starts long before the final polish. While many consumers imagine today’s gua sha tools as fully machine-made products, the truth is that the best-quality tools still rely heavily on skilled manual work. Among these steps, hand-drawing the gua sha shape on stone slabs before cutting is one of the most critical stages.

This article explains how gua sha tools are made, why manually drawn outlines are important, how this process reduces waste by 20% and increases final product quality by 15%, and why human expertise continues to outperform fully automated systems when working with natural stone.

Understanding What Gua Sha Tools Are Made From

Natural Stones and Their Unique Structures

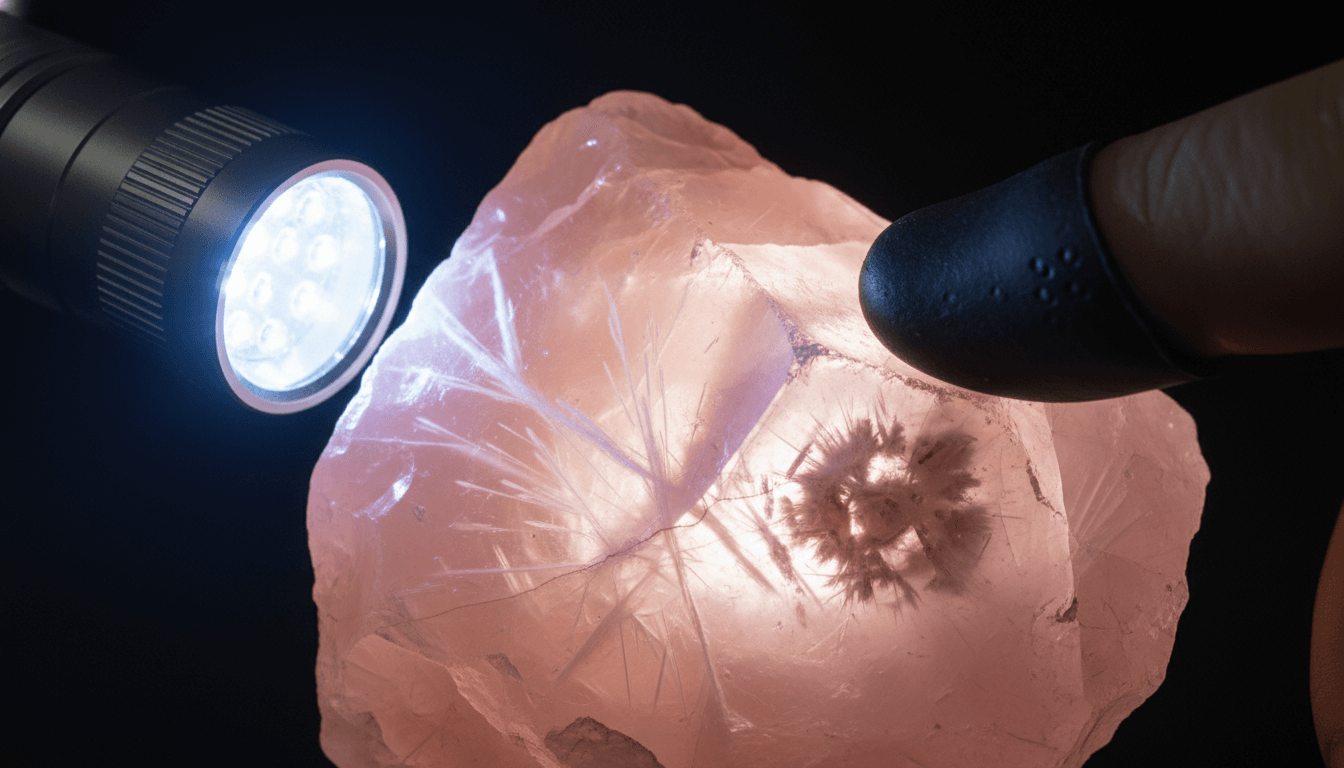

Most gua sha tools are carved from natural stones such as rose quartz, jade, amethyst, obsidian, or aventurine. Natural stone, however, is far from uniform. According to the Gemological Institute of America (GIA), natural minerals often contain inclusions, microcracks, color zoning, or structural irregularities caused during geological formation (Source: https://www.gia.edu/gemstone-inclusions). These features, while natural, create challenges in manufacturing.

For a gua sha tool, even a tiny internal fracture can cause breakage during shaping or later during use. Machine vision is still limited in detecting subtle, hairline cracks within the stone. Human inspection remains more accurate.

Quality Standards for Beauty-Grade Stones

Stones used in facial tools must meet stricter standards than stones used for general crafts. The European Chemicals Agency (ECHA) notes that materials used for cosmetic-contact products must avoid toxic minerals and maintain structural stability (Source: https://echa.europa.eu).

This means factories must examine not only appearance but also internal composition. A hand-drawn mapping of the gua sha shape helps avoid questionable zones, ensuring safety and durability.

Overview of the Gua Sha Manufacturing Process

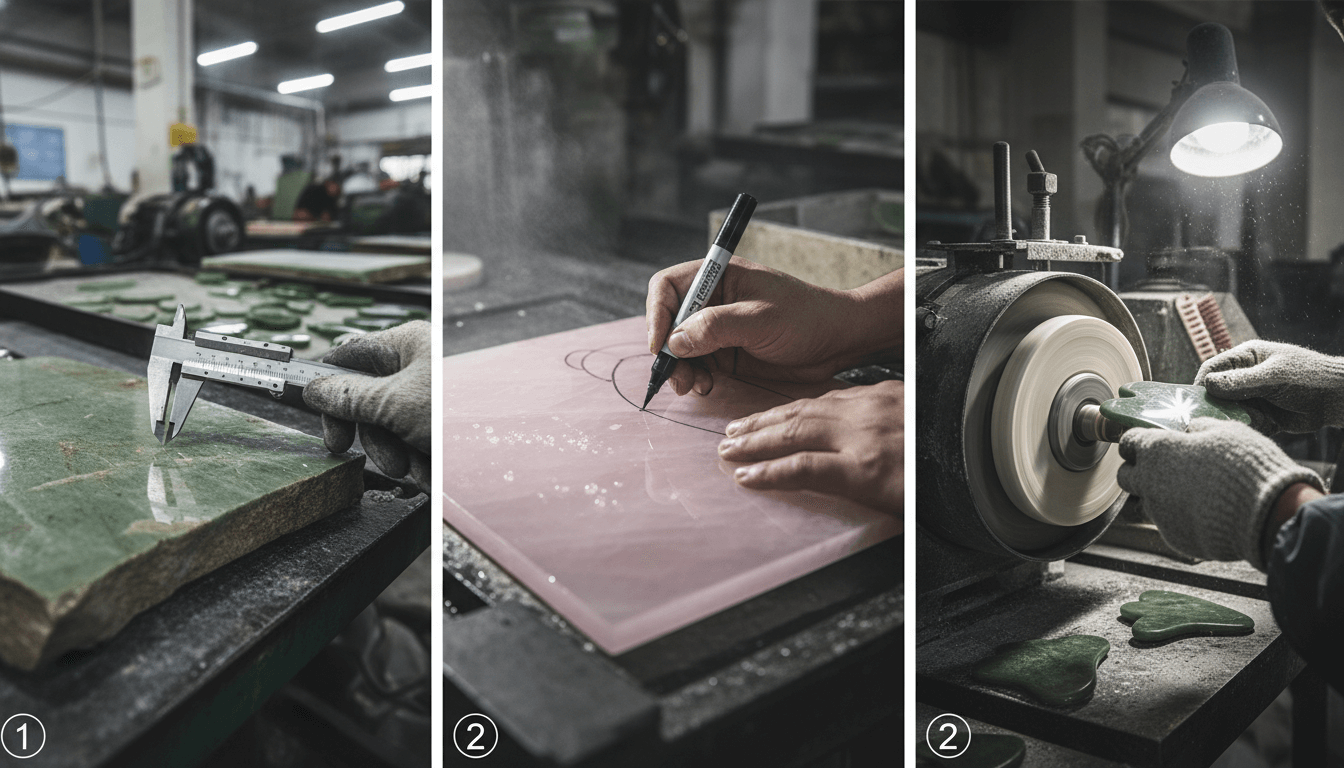

Step 1: Stone Selection and Initial Inspection

The production process begins by selecting large stone blocks or slabs. These slabs are inspected under bright lighting to identify visible cracks, impurities, or density inconsistencies. Studies by the Mineralogical Society of America indicate that natural stone density can vary by 10–15% even within the same mineral batch (Source: http://www.minsocam.org).

Such differences influence how well the stone can endure grinding and polishing, which is why hand inspection remains essential.

Step 2: Cutting the Stone Into Plates

Large blocks are cut into thin plates, usually 5–7 mm thick, depending on the final gua sha design. Thickness consistency ensures that finished gua sha tools feel balanced in the hand and deliver uniform pressure during use.

Machine cutting guarantees even thickness, but machines still cannot determine where internal cracks lie.

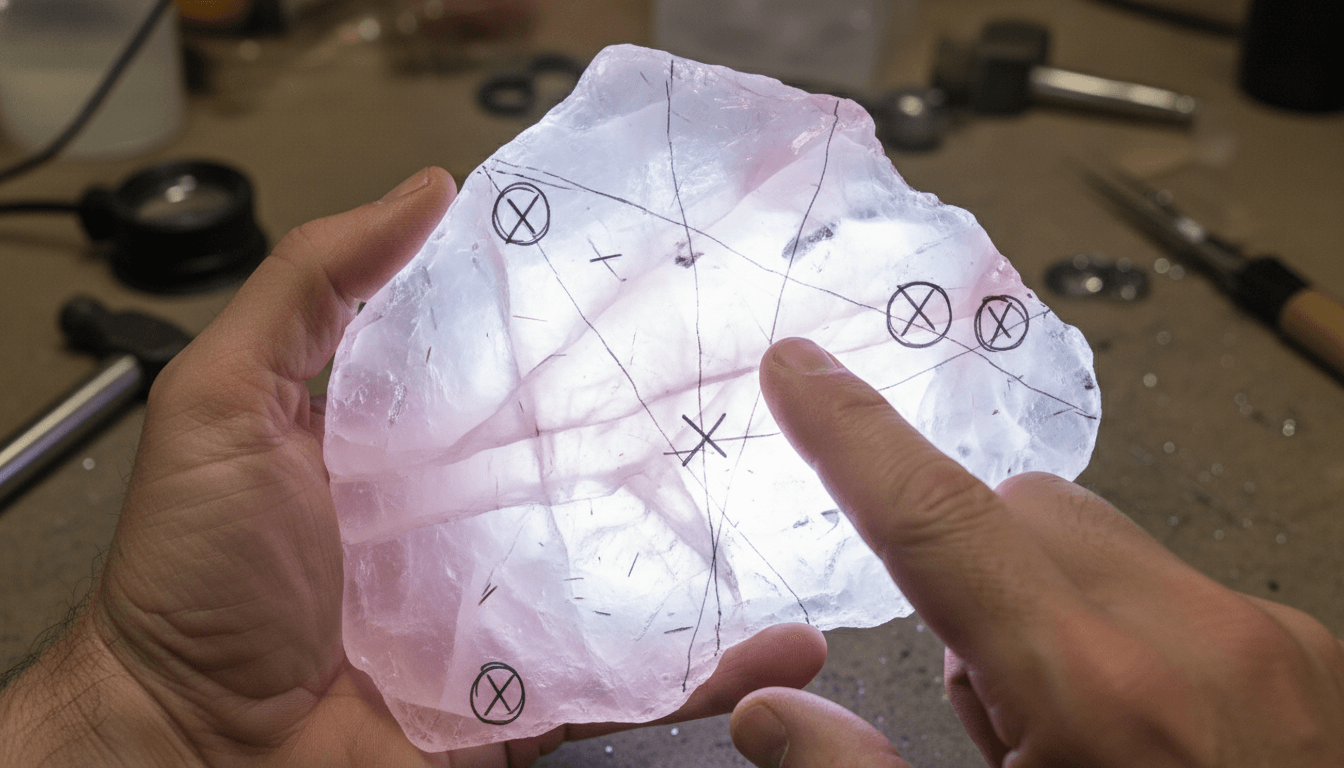

Step 3: The Hand-Drawn Shape Process (Most Critical Stage)

This stage is where the artisan’s experience makes the greatest impact. Craftsmen examine each stone plate, check for color variations, fractures, and mineral specks, and then manually draw multiple outline options on the slab.

At Deyi Gems, our internal data demonstrates:

- Material waste decreases by 20%

- Finished-product quality increases by 15%

when shapes are drawn manually instead of using automated templates.

The reason is clear: humans identify internal imperfections better than any machine currently available.

Step 4: Rough Shaping and Grinding

Once the outline is drawn, machines cut along the line to create the rough gua sha shape. Approximately 60–70% of extra stone material is removed at this stage. If the outline intersects a hidden crack, the piece may break. Hand drawing reduces these breakages significantly.

Step 5: Fine Grinding and Edge Formation

After rough shaping, artisans manually grind the edges to achieve the signature gua sha curves. This step requires careful attention so the tool feels comfortable in the user’s hand and glides smoothly on the skin.

Step 6: Polishing

Polishing determines a tool’s smoothness and safety. Cosmetic-grade tools typically must reach a surface roughness of Ra < 0.2 μm, a standard referenced in ASTM engineering surface roughness norms. Multiple rounds of polishing—from coarse to fine to felt wheel—are required.

This creates a smooth, glossy finish that ensures an effortless glide.

Why Hand-Drawn Gua Sha Shapes Matter

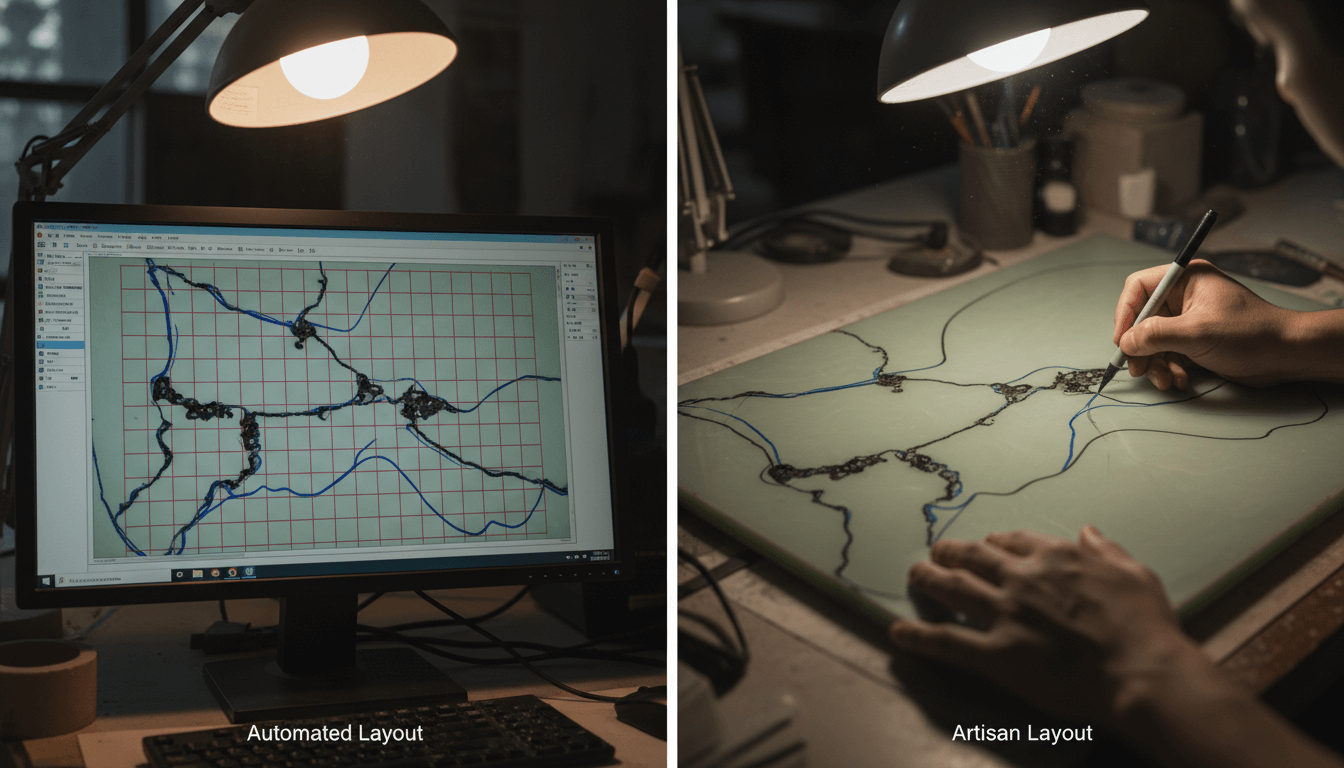

The Limitations of Fully Automated Manufacturing

Automated shape cutters use preset templates and computer imaging. While efficient for synthetic materials, they struggle with natural stones. Tiny fractures invisible to machine sensors can cause pieces to crack during grinding or polishing.

Manual inspection allows artisans to tilt the slab under light, tap it for sound differences, and check reflective patterns—techniques machines cannot replicate accurately.

Unlike metal or ceramic, natural stone varies in color, texture, grain direction, and density. Automated layout software assumes the material is uniform, which is rarely true. Skilled workers can visually scan and adjust shapes based on the slab’s natural characteristics, maximizing usability.

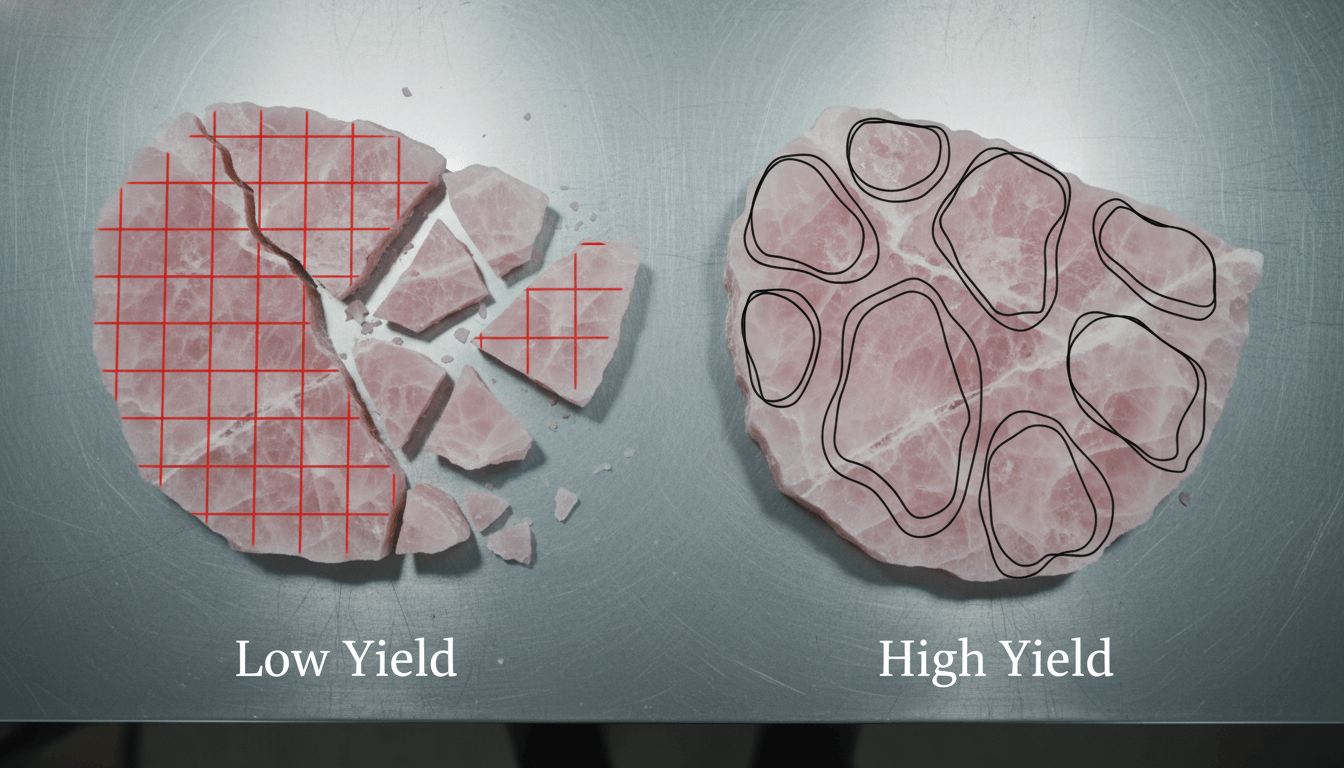

How Hand-Drawn Shapes Reduce Waste

Data From Our Factory: 20% Less Waste

Based on internal measurements at Deyi Gems, manual shape mapping reduces material waste by roughly 20%. This is because the artisan avoids areas with:

- Microcracks

- Mineral impurities

- Soft mineral veins

- Structural inconsistencies

Machines, on the other hand, apply identical shapes across the slab, leading to higher breakage rates.

Better Positioning = More Usable Pieces

A stone slab that might produce 10 automated-cut pieces could yield 12 pieces with hand mapping. This increased yield directly impacts cost efficiency and environmental sustainability.

How Hand-Drawn Shapes Improve Quality

Finished Tool Strength Improves by About 15%

Because artisans choose the strongest parts of the stone, finished gua sha tools experience fewer breakages during fine grinding or packaging. Tools made from flawed zones are more likely to snap or chip.

Internal data from our production shows a 15% improvement in structural integrity for hand-drawn pieces.

More Consistent Color and Texture

Hand drawing lets artisans choose visually consistent regions of the slab. This results in gua sha tools with more uniform color and fewer visible defects—crucial for premium-grade products.

A Deep Look Into the Hand-Drawing Process

How Craftsmen Examine Stone Slabs

- Step 1: Surface Lighting Inspection

Strong white lighting reveals color zoning, cracks, and inclusion clusters. This is similar to gem inspection methods recommended by GIA.

- Step 2: Sound Testing

Tapping the stone helps identify internal fractures. Clear sound = stable structure. Dull sound = crack or soft vein.

- Step 3: Marking Potential Shapes

Workers often draw multiple shape options, then select the layout that produces the most usable pieces.

Why Shape Drawing Is an Artistic Skill

- Balancing Natural Beauty With Structural Strength

Artisans must ensure the gua sha shape follows the natural flow of the stone grain. Grain direction affects both appearance and durability.

- Matching Curves to the Stone Structure

Certain shapes, such as the “S-shape” or “heart shape,” require more precise mapping. An experienced worker ensures the curves avoid fragile areas.

Comparison: Hand-Drawn vs. Automated Template Cutting

Accuracy and Precision

- Machines Produce Consistent Shapes

Automated systems excel at duplicating exact shapes quickly.

- Humans Make Better Structural Decisions

Human judgment ensures that each shape is placed where the stone is strongest, even if that means repositioning the template.

Environmental and Economic Impact

- Lower Material Waste

Since hand drawing produces more usable pieces per slab, fewer stone blocks need to be mined or purchased.

- Reduced Breakage During Production

Fewer broken pieces mean lower energy, less polishing time, and more consistent inventory.

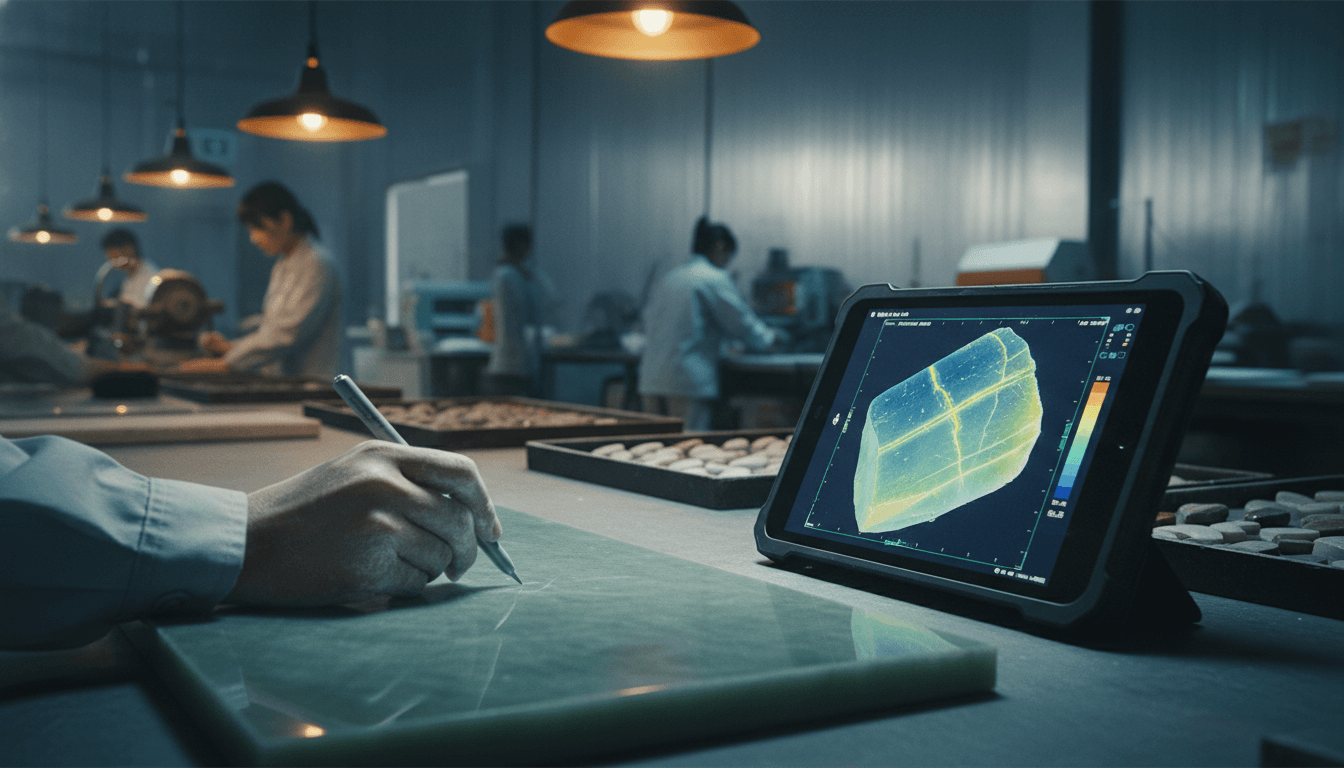

Future Trends in Gua Sha Manufacturing

Hybrid Production Methods

- Combining AI Layouts With Human Judgment

Some factories experiment with AI-based stone-scanning tools. However, natural stones remain too variable for full automation. The best results come from combining both.

- Growing Demand for Transparent Manufacturing

Consumers increasingly care about sustainability and craftsmanship. Brands that highlight hand work and waste reduction appeal more to modern buyers.

Conclusion

Gua sha tools may look simple, but their creation is a complex balance of geology, craftsmanship, and engineering. The hand-drawn shape stage—often overlooked by consumers—plays a critical role in ensuring that each tool is strong, beautiful, and durable.

At Deyi Gems, our decades of experience working with natural stone have proven that skilled artisans are irreplaceable. Their ability to read a stone’s natural structure reduces waste by 20%, improves quality by 15%, and helps us deliver premium gua sha tools trusted by global brands.

As the wellness industry continues to evolve, the value of thoughtful, handcrafted production remains as important as ever.