As an editor at Deyi Gems and someone who has worked in the gua sha and beauty-tool supply chain for years, I’ve seen both jade and ceramic gua sha rise in popularity. Both are common on spa shelves and in influencer feeds, yet they come from very different material families and manufacturing processes — which affects how they perform, how they feel, how long they last, and how they should be cared for. In this deep-dive comparison, we’ll examine jade and ceramic gua sha from two angles: the production side (sourcing, shaping, finishing, quality control, costs, and sustainability) and the user side (thermal feel, glide, durability, hygiene, and results). Along the way I’ll point to authoritative sources so you can verify the technical claims and make an informed choice for your brand, salon or personal routine.

Why the keywords matter

What “jade gua sha” signals

When suppliers or customers say “jade gua sha,” they usually mean tools cut from natural jade stone — most often nephrite or jadeite. These are true gemstones with geological and gemological attributes (hardness, density, toughness) that influence carving, finish and long-term wear. Because jade is a recognized gemstone in jewelry and art markets, authenticity and provenance matter to both producers and buyers.

GIA — Jade care, properties and Mohs hardness (useful for sourcing and authenticity checks).

What “ceramic gua sha” signals

“Ceramic gua sha” refers to tools manufactured from fired clay bodies — typically porcelain or high-fired ceramic — and finished with a smooth glazed surface. Ceramics are engineered in a kiln: raw materials are blended, shaped, fired at high temperatures, and then often glazed and refired. This production route makes ceramic tools highly controllable in form, texture and color, while also allowing features such as thin edges and repeatable molds.

Sowelab / ceramic gua sha product notes — ceramic properties and manufacturing notes.

Material science and production (the factory perspective)

Jade — geology, sourcing, and stone preparation

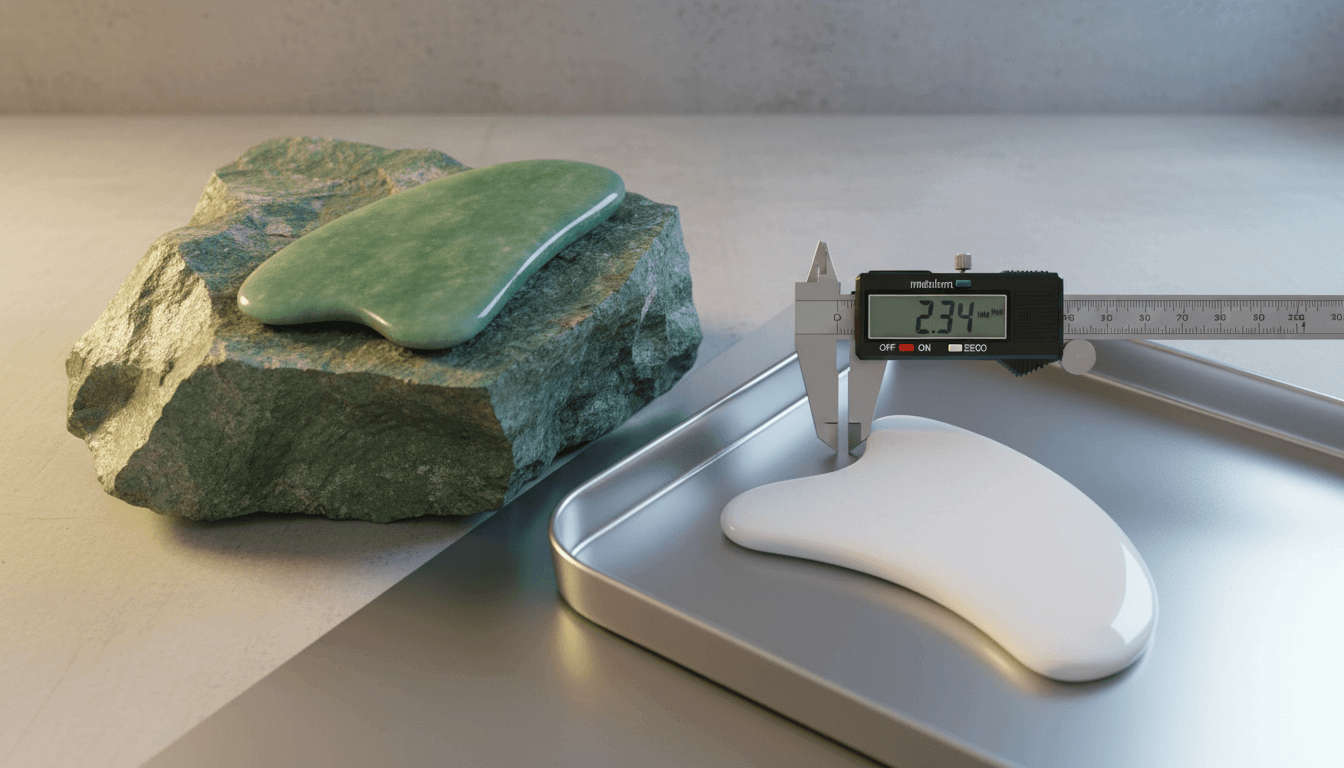

Jade used for gua sha primarily comes in two mineral types: nephrite and jadeite. They differ subtly in chemical makeup, density and hardness: nephrite is typically around Mohs 6–6.5, while jadeite sits around Mohs 6.5–7. That range matters to a factory because harder stone may take longer to cut and polish but can achieve finer polish and sheen. Mining locations, slab quality, and the presence of fractures or inclusions determine yield: high-quality, isotropic slabs (without many veins) are rarer and costlier. Gemological care and testing (e.g., to rule out dyed or polymer-impregnated fakes) are routine for reputable suppliers.

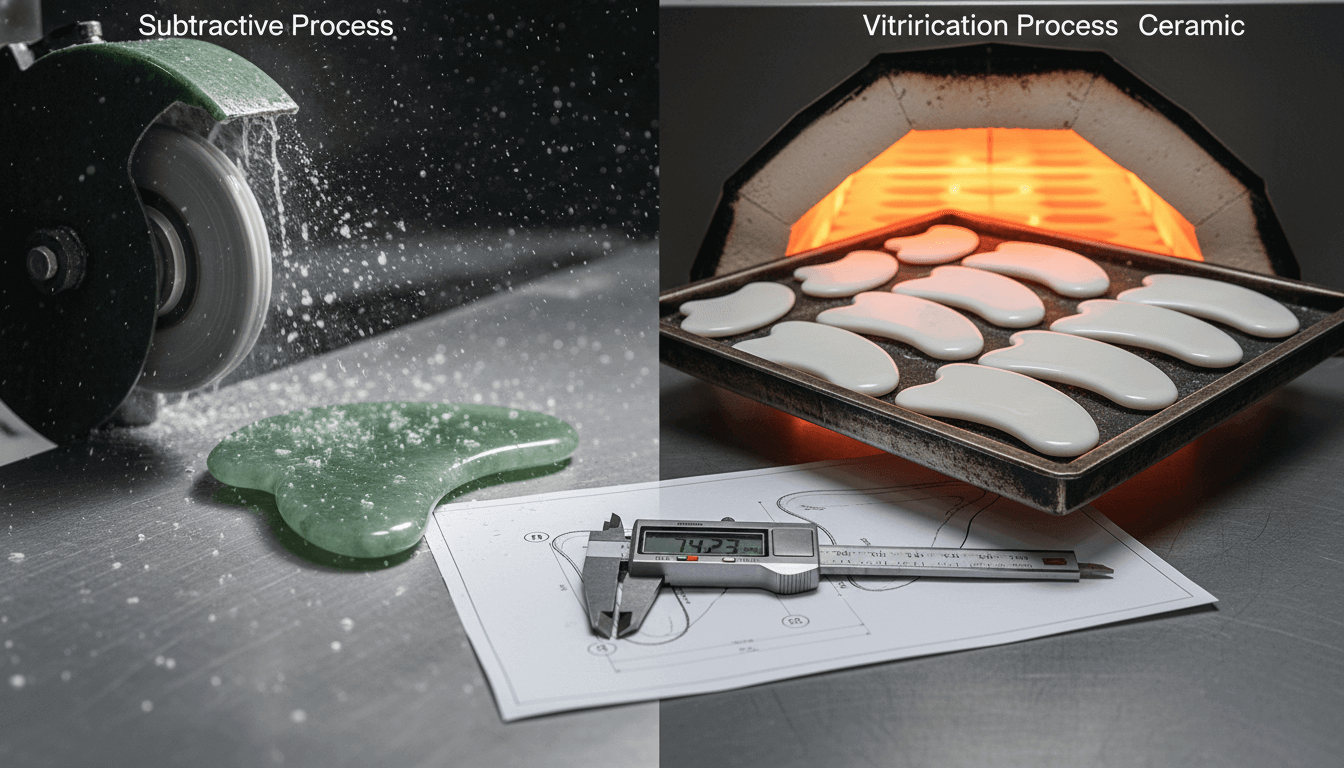

Jade — shaping, tooling, and finish

Working jade is a craft. Common production steps include slab splitting, rough sawing to shape blanks, CNC or hand-shaping, multi-stage grinding, and progressively finer polishing to bring out luster. For larger orders, factories often combine machine cutting with manual finishing to maintain consistent shapes while preserving stone integrity. Quality control focuses on edge tolerances, polish uniformity, and chip-free surfaces. For premium jade, additional steps like ultrasonic cleaning and hand-polishing are used to reduce micro-abrasions that could irritate facial skin.

“How top gua sha factories produce” — practical step-by-step production workflow for stone tools.

Ceramic — materials, forming and firing

Ceramic gua sha production is more industrially repeatable. A porcelain or ceramic body is formulated to flow and vitrify predictably in a kiln. Tools can be slip-cast, pressed, or machine-cut from molded blanks. After an initial bisque firing, surfaces are glazed and fired again at controlled temperatures to create the final hard, glass-like surface. This process gives manufacturers excellent control over thickness, edge radius and surface smoothness, and it supports consistent color and patterning across large runs. Ceramic tooling requires investment in molds and kiln capacity but scales efficiently.

Ceramic — finishing and surface properties

A well-formulated glaze can yield an ultrafine, non-porous surface that feels silky on skin and resists staining. Some ceramic makers advertise thermoregulatory properties (a neutral feel against skin) and antibacterial benefits derived from a fully vitrified, non-porous surface. In practice, ceramic’s surface chemistry makes cleaning straightforward because oils and serums don’t penetrate the body as they might with unfinished natural stones. However, chips can expose raw ceramic body and create roughness if dropped.

Quality control, testing and regulatory considerations

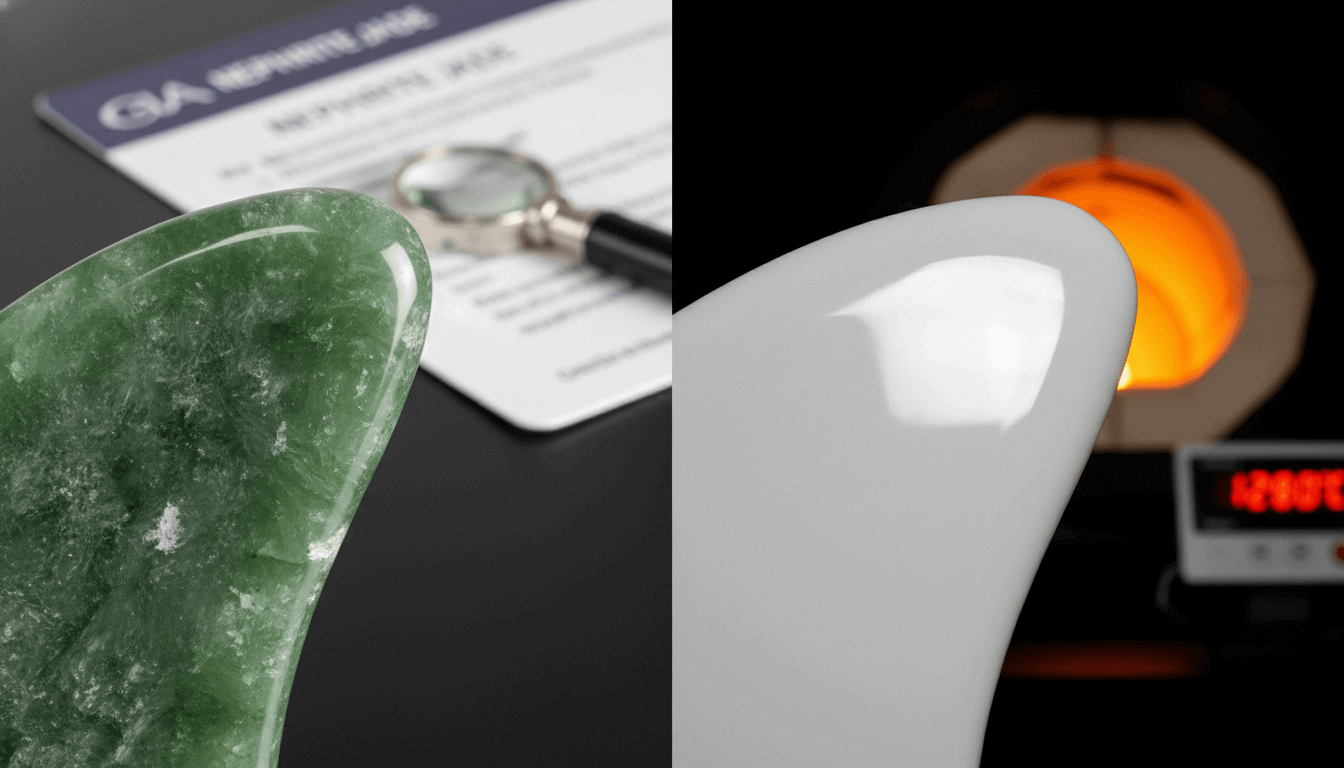

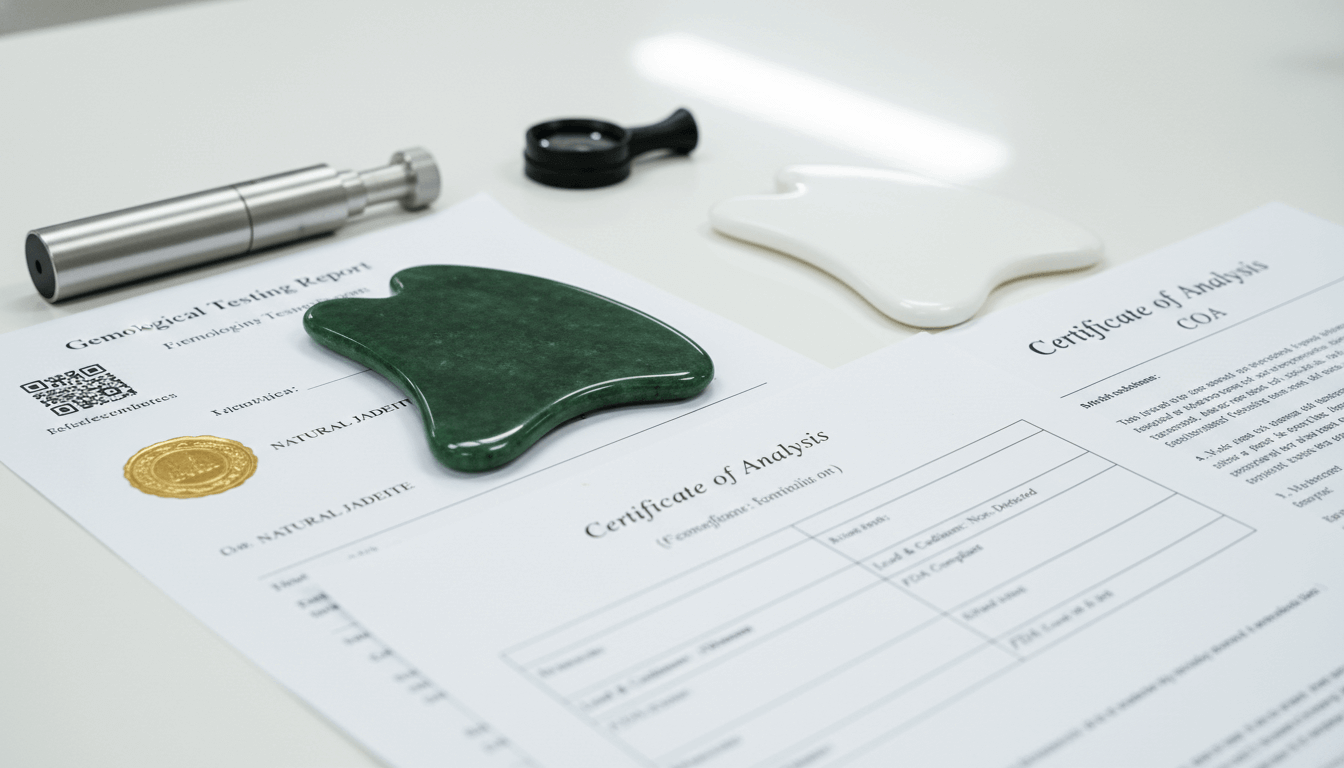

Authenticity and material testing for jade

From a factory standpoint, testing is non-negotiable. Reputable suppliers perform gemological checks: specific gravity, refractive indices when necessary, and — increasingly — spectroscopic or lab reports for higher-value jadeite pieces. The market has many treated, dyed or polymer-impregnated “jade-like” products; therefore, certification helps brands avoid reputational risk and regulatory headaches in export markets. Moreover, for wholesale clients who will sell under a brand, traceability and consistent batch documentation are competitive advantages.

Consistency and safety for ceramic

Ceramic production requires materials testing to verify firing schedules and glaze compatibility, particularly to ensure there are no heavy metals leaching from certain glazes. Lead- or cadmium-containing glazes are rare in modern cosmetic tools, but buyers should still request certificates of analysis (CoA) and test reports. A ceramics factory’s process control (recipe logs, kiln records, and glaze testing) is the equivalent of a gem lab report for jade: it proves consistency and safety.

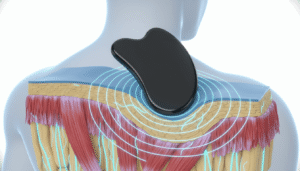

How the tools perform in real use (the user perspective)

Thermal feel and immediate tactile impression

One of the most commonly cited reasons people choose jade is its perceived “coolness.” Jade does tend to feel cool to the touch, which can enhance the sensory experience during facial gua sha. That cool feel comes from the stone’s thermal mass and conductivity. Ceramic, depending on firing and glazing, may feel neutral and less icy than jade; however, some consumers prefer the milder temperature because it’s less likely to create sudden sensations on sensitive skin. Both materials are often chilled in the fridge by at-home users or therapists to amplify de-puffing effects.

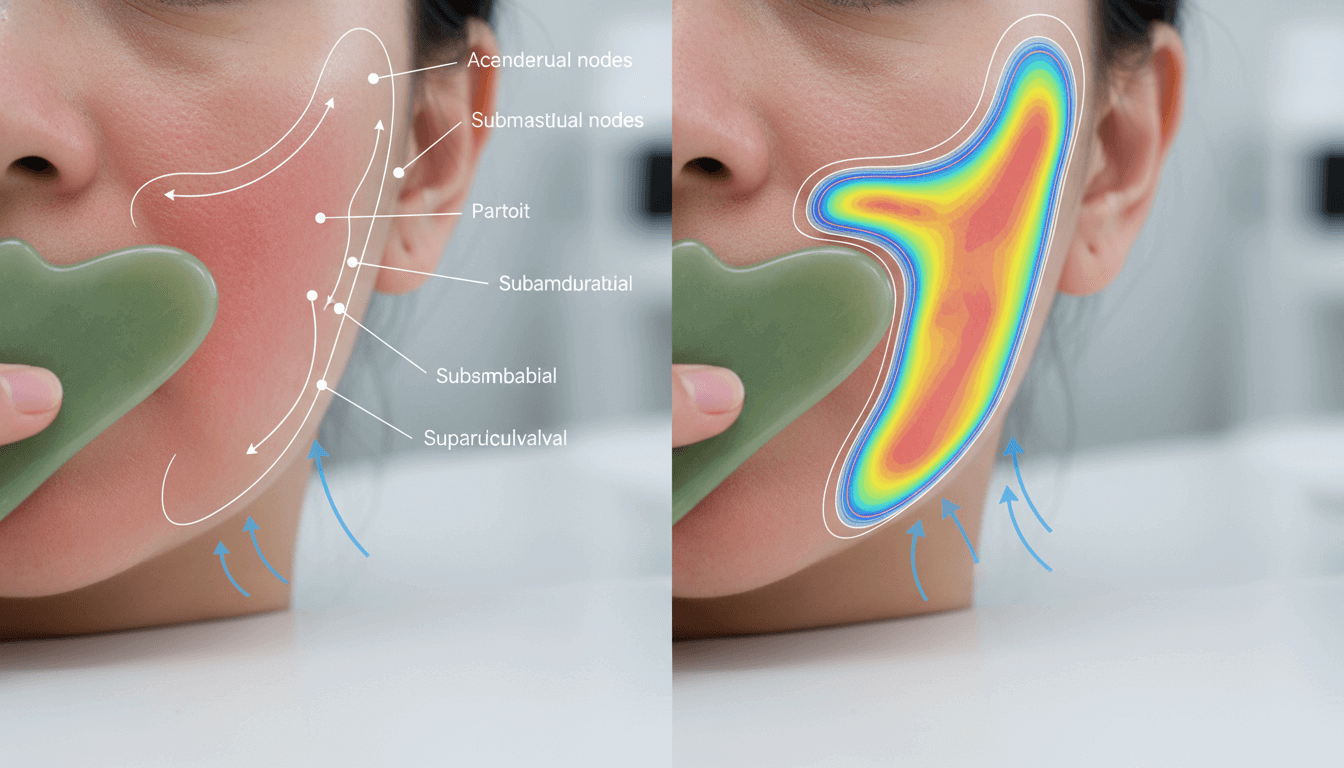

Glide, friction and the role of surface finish

A critical factor in user experience is how smoothly the tool moves across skin when used with oil or serum. A high-polish jade tool, when properly finished, glides very smoothly because the stone’s microtopography is minimized by polishing. Likewise, a well-glazed ceramic can be equally slick. The difference is that ceramic’s surface is engineered and repeatable, whereas stone finish quality depends more on polishing skill and the inherent grain of the jade. Therefore, two “high-quality” gua sha pieces — one jade and one ceramic — can perform similarly in glide.

guashawholesale.com — gua sha production process and factory workflow (practical production notes)

Durability and the risk of chipping or breaking

From a practical perspective, jade is a tough material — especially nephrite which is known for its toughness — and can withstand years of gentle use when handled properly. However, it is not indestructible: drop it onto a hard surface and chips or cracks may appear. Ceramic is harder and more brittle in different ways; the fired glaze and body can be very hard but may shatter or chip on impact. For users who travel frequently or who drop tools often, the risk profile differs: jade can chip but sometimes resists shattering, whereas ceramic can chip or break more completely depending on its formulation and thickness.

Hygiene, cleaning and maintenance

Hygiene is essential for any tool used on skin. Ceramic’s fully glazed, non-porous surface is easy to clean and is naturally less likely to harbor bacteria when cleaned properly. Jade is also relatively low-maintenance and many jade tools are non-porous after polishing; however, natural stone can have micro-fissures or microscopic pores in some lower-quality pieces, and dyes or polymer treatments complicate cleaning and safety. For salon use, both materials should be cleaned between clients with appropriate detergents and, when needed, disinfected according to local regulations. Evidence supports benefits of gua sha techniques for circulation and lymphatic flow, but proper hygiene and technique must be followed to avoid skin irritation.

Evidence and outcomes — what science says about gua sha results

Clinical and dermatological reviews show that gua sha increases local blood flow and may affect lymphatic movement, which explains transient reductions in puffiness and enhanced skin glow for many users. However, high-quality, long-term clinical evidence for structural facial contour change is limited; most benefits are measurable short-term physiological responses and subjective relaxation or cosmetic improvements. This means that regardless of tool material, technique and consistency matter more than the stone or ceramic itself when it comes to outcomes.

Production-cost and supply-chain comparison

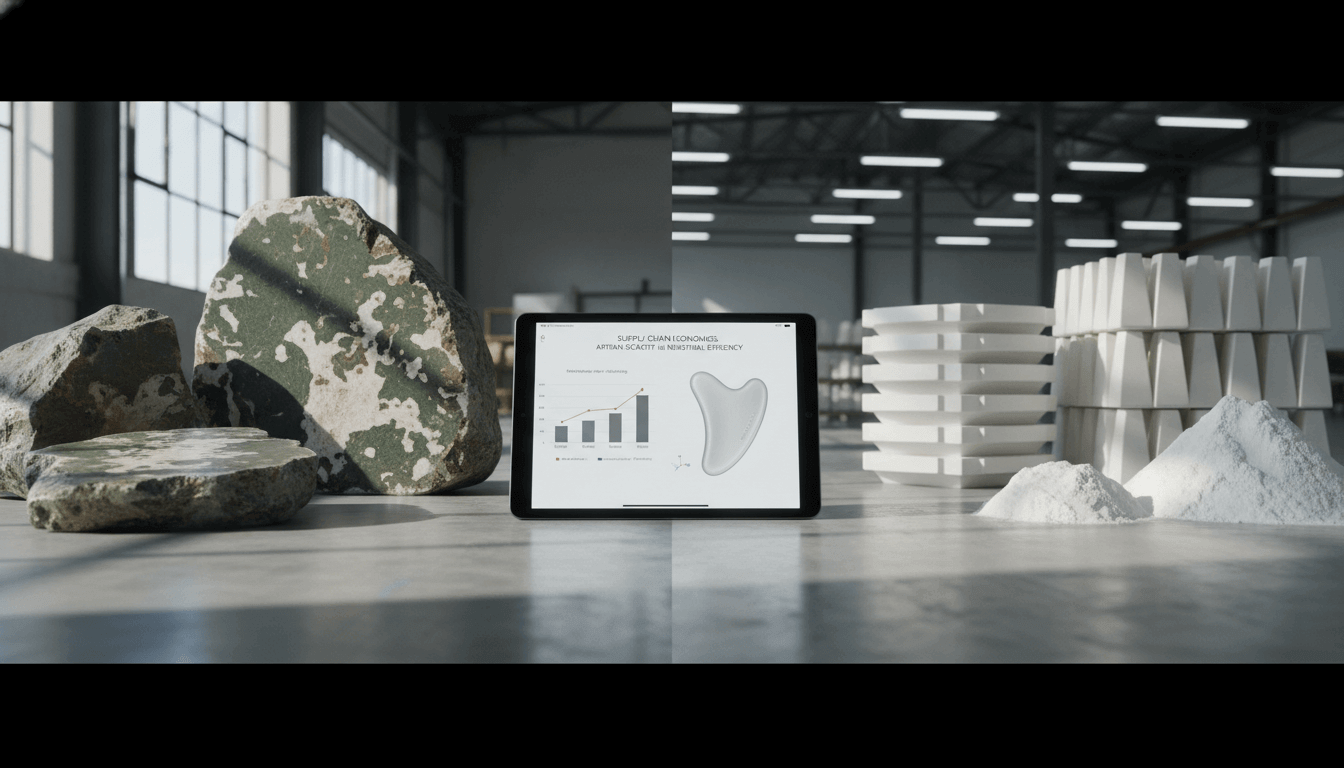

Raw-material procurement and cost volatility

Jade’s cost is linked to mining supply, gem-quality grade and market trends; higher-grade jadeite can be costly and subject to commodity-like price swings. This affects factories and wholesalers: low-cost gua sha pieces are often made from lower-grade jade, dyed stone, or alternate materials. Ceramic raw materials (kaolin, feldspar, clays) are industrial commodities with more predictable pricing and steady supply, which makes cost planning easier for large runs. From a brand’s manufacturing standpoint, if you need large, low-variance runs, ceramic often gives better margin predictability.

Production lead time, scalability, and tooling

Ceramic production benefits from molds, casting tables and kilns; once molds and glaze recipes are finalized, scaling to thousands of identical pieces is straightforward. Jade production requires more skilled labor: slab selection, hand-finishing and individual stone variability make exact replication difficult. Consequently, ceramic can be faster and cheaper for large SKUs, while jade commands a premium and longer lead times for high-quality, consistent batches.

Waste, sustainability and environmental footprint

Mining jade has a heavier environmental footprint than clay extraction because gemstone mining can disturb ecosystems and generate waste. Ceramic production uses energy (kilns) and has emissions tied to firing; however, kiln efficiency, fuel type and waste handling can be optimized. If sustainability is a selling point for your brand, ask suppliers for environmental disclosures: where the stone was mined, whether the quarry is rehabilitated, kiln efficiency, and whether glazes are free of heavy metals. These data points are increasingly requested by retailers and consumers.

Branding and consumer perception

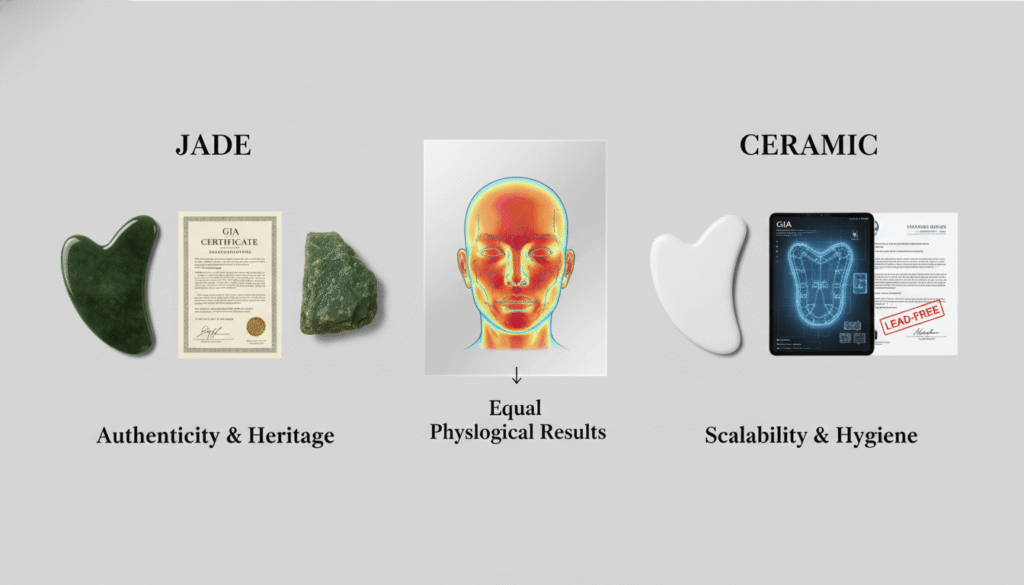

The “luxury” signal of jade

Jade carries heritage and luxury signaling. Many consumers associate jade with traditional Chinese beauty practices, longevity, and natural gemstones. That cultural resonance can justify higher price points and positions jade gua sha as premium or artisanal. For brands targeting luxury customers or storytelling about traditional roots, real jade offers marketing advantages — provided authenticity is proven.

The “design and hygiene” signal of ceramic

Ceramic tools often appear in modern, minimalist aesthetics: consistent colorways, matte or glossy glazes, and custom printed logos are easier to achieve. Ceramics are favored by brands that emphasize hygiene, repeatability and clean design, especially under spa or medical-grade narratives. For salons that prioritize sterilizable surfaces and consistent performance, ceramic products can be easier to standardize.

Practical recommendations — who should choose which

For professional salons and therapists

If your salon needs a consistent, easy-to-clean tool that you can buy by the dozen and treat as an instrument, ceramic is often the best practical choice. It offers repeatable shape, edge radius and surface, and can be matched to a suite of tools for consistent client experience. That said, many high-end spas prefer jade for aesthetic and ritual reasons — in that case, insist on certified, high-polish stone and implement strict cleaning protocols between clients.

For home users and gifting

For at-home users, both materials work well. If you prioritize tradition and that cool, gemstone feel, choose a mid- to high-quality jade gua sha from a seller who provides material information. If you prioritize low maintenance and color choices, choose ceramic. For gifts, jade carries stronger perceived value and story. Ensure the seller provides care instructions and authenticity information if the price is high.

For brands and private-label product managers

If you are launching a private label and need predictable cost-per-unit and shape standardization, ceramic reduces production risk and speeds up time-to-market. If you want to position a product as artisanal, heritage-driven, or collectible, jade can justify premium placement but requires stronger supply-chain controls, authenticity documentation, and a higher quality assurance budget. Consider offering both: a ceramic line for accessibility and a jade line for prestige.

Care and cleaning (practical user guidance)

Both jade and ceramic gua sha tools should be cleaned after each use. Use mild soap, warm water and a soft cloth; avoid boiling stones or soaking them for long periods. For salon environments, follow local disinfection protocols and confirm that any disinfectant is safe for the material and finish (some alcohol-based or acid cleaners can dull polish or attack certain glazes). For jade, avoid harsh chemicals and high heat; for ceramic, avoid abrasive pads on the glaze to reduce the chance of micro-scratches. Proper storage (padded pouch or box) reduces the risk of chipping for either material.

Summary — pros and cons at a glance (narrative form)

In short, jade gua sha tools bring cultural cachet, a naturally cool feel, and gemstone appeal that many consumers love; however, they require careful sourcing, testing and often more expensive production steps. Ceramic gua sha tools provide industrial repeatability, easy hygiene, and design flexibility at scale, but can be brittle in certain drop scenarios and lack the gemstone story. From a scientific standpoint, gua sha’s immediate benefits are driven more by technique than by material: both materials can deliver the same physiological effects when used correctly. Therefore, your choice should align with your business goals: authenticity and premium positioning (choose jade), or scalability, hygiene and design control (choose ceramic).

Practical checklist for buyers and brands

Before finalizing a supplier, ask for the following documentation and checks:

- For jade: origin statement, treatment disclosure (dyed, impregnated or untreated), and any lab reports for high-value shipments.

- For ceramic: CoA for glazes (lead/cadmium-free), firing logs and sample batch photos to check for glaze defects.

- For both: photos of the actual production process, QC procedures, edge radius tolerances, and standardized packaging samples.

These requests protect you from quality surprises and help maintain brand trust with customers. Reputable suppliers will welcome these questions; if a vendor resists, consider it a red flag.

Closing / Final recommendation

Both jade and ceramic gua sha tools have legitimate places in the modern beauty toolkit. If you sell to consumers who value heritage, storytelling and a gemstone feel, invest in verified, high-quality jade with clear provenance. If your priority is product consistency, sterilizable surfaces for clinical settings, or low-cost scalability for large SKUs, ceramic will serve you better. For many brands and salons, the ideal approach is to offer both: a premium jade line for storytelling and gifting, and a ceramic line for daily professional use — that way you meet multiple customer needs while controlling production risk. If you’d like, I can draft a supplier vetting checklist tailored to your MOQ, target price points, and target markets (spa vs retail), or create product page copy for a jade vs ceramic product pair that highlights these differences for customers.

Selected references and further reading

- GIA — Jade care, properties and Mohs hardness (useful for sourcing and authenticity checks).

- PubMed / J. Cosmet. Dermatol. review (2023) — evidence summary on gua sha, rollers, and facial massage.

- Sowelab / ceramic gua sha product notes — ceramic properties and manufacturing notes.

- guashawholesale.com — gua sha production process and factory workflow (practical production notes).

- “How top gua sha factories produce” — practical step-by-step production workflow for stone tools.