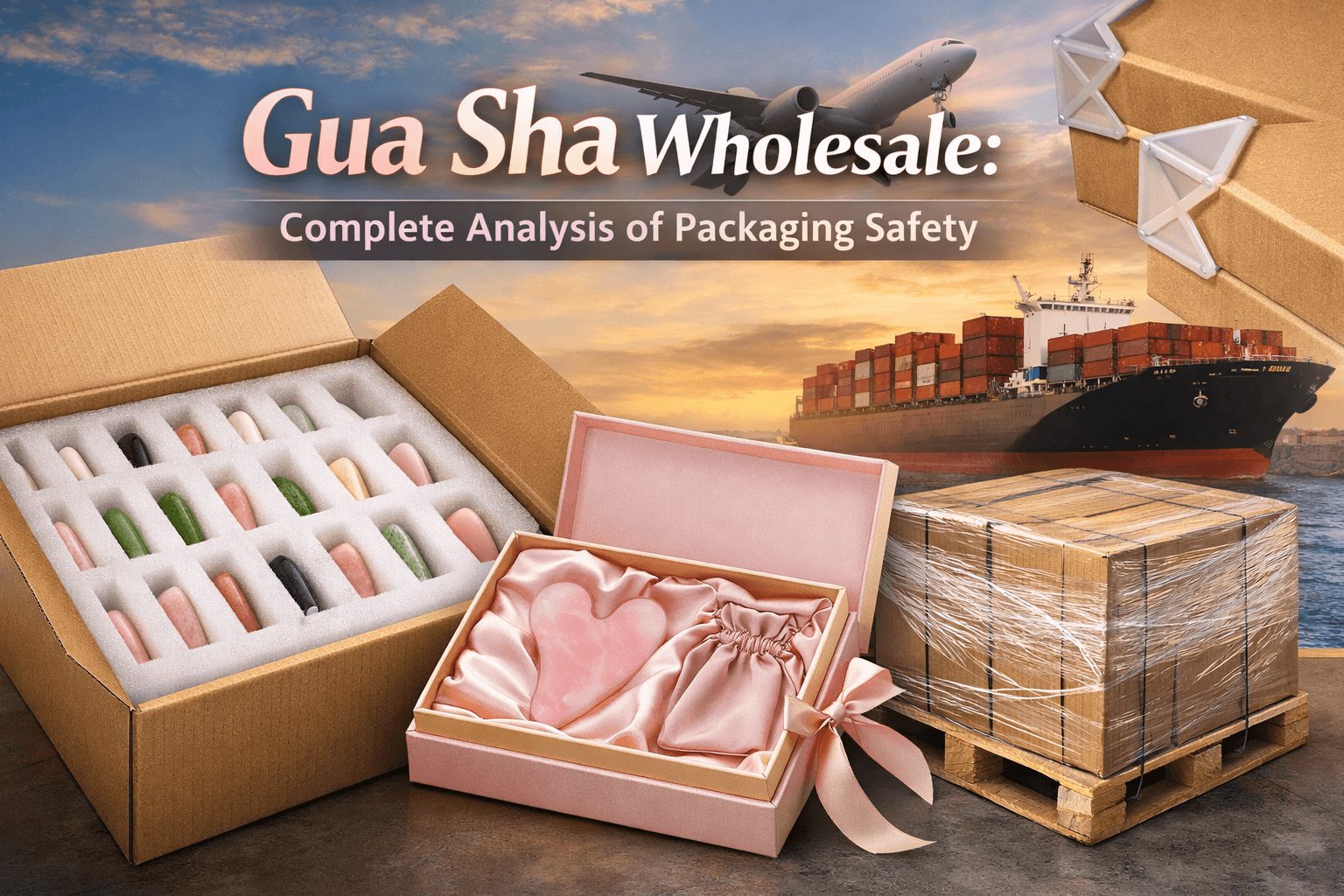

In the global beauty and wellness market, gua sha tools have evolved from traditional therapy instruments into mainstream skincare and facial massage products. As demand grows across North America, Europe, and emerging markets, gua sha wholesale buyers are no longer focused solely on material quality, shape, or pricing. Packaging safety has become an equally critical factor that directly affects product integrity, brand reputation, logistics costs, and customer satisfaction.

From a wholesale perspective, gua sha packaging is not just about appearance. It is a systematic process that must protect fragile stone tools throughout long-distance transportation, multi-stage handling, and storage. Even a perfectly crafted jade or quartz gua sha tool can arrive cracked or chipped if packaging design and transport protection are inadequate. Therefore, understanding packaging safety is essential for brands, distributors, and importers operating at scale.

In this comprehensive guide, we will analyze gua sha wholesale packaging safety from a professional manufacturing and industry standpoint. Drawing on years of experience in gua sha production and export, this article explains how packaging is structured, tested, and optimized for both bulk and individual units. At the same time, the content is written in clear, accessible English to ensure it is practical for readers at all levels of industry experience.

Understanding Gua Sha Wholesale Packaging in the Beauty Supply Chain

The Role of Packaging in Wholesale Distribution

In gua sha wholesale, packaging acts as the first line of defense between the product and external risk factors. These risks include vibration, compression, impact, humidity, and temperature changes during shipping. Unlike mass-produced plastic tools, gua sha stones are inherently brittle due to their crystalline structure, which makes them vulnerable to micro-fractures and edge damage.

Packaging in wholesale distribution must therefore serve multiple functions simultaneously. It must protect the product physically, maintain consistent quality across large quantities, and support efficient logistics handling. At the same time, it should align with brand positioning, whether the brand emphasizes luxury, sustainability, or clinical professionalism.

According to the International Safe Transit Association (ISTA), over 30% of product damage in international shipping is related to insufficient or poorly designed packaging rather than manufacturing defects. This data highlights why packaging safety must be integrated into wholesale strategy rather than treated as an afterthought

(https://ista.org).

Differences Between Retail Packaging and Wholesale Packaging

Retail packaging is often designed with the end consumer in mind, focusing on visual appeal and shelf presence. Wholesale packaging, however, prioritizes structural stability and transport efficiency. In gua sha wholesale, these two packaging layers must work together rather than compete with each other.

Wholesale packaging typically includes outer cartons, protective inserts, and palletization systems. Retail packaging, such as individual boxes or gift sets, is then placed inside this outer protective structure. If the dimensions or materials are mismatched, damage can occur even if each layer appears strong on its own. Therefore, coordination between wholesale and retail packaging design is a key principle in safe gua sha distribution.

Material Characteristics and Their Impact on Packaging Safety

Why Gua Sha Stones Require Special Protection

Gua sha tools are commonly made from jade, rose quartz, amethyst, obsidian, or other natural stones. These materials vary in hardness, density, and internal structure. While some stones are harder on the Mohs scale, they may still contain internal fissures that make them susceptible to impact damage.

Because stone tools do not flex under pressure, even minor collisions can result in chips or hairline cracks. This characteristic means packaging must not only cushion external shocks but also prevent internal movement. Allowing gua sha tools to collide with each other is one of the most common causes of damage in wholesale shipments.

The Gemological Institute of America (GIA) explains that natural gemstones often contain inclusions that are invisible to the naked eye but can weaken structural integrity under stress

(https://www.gia.edu). This reinforces the need for packaging systems that isolate each tool during transport.

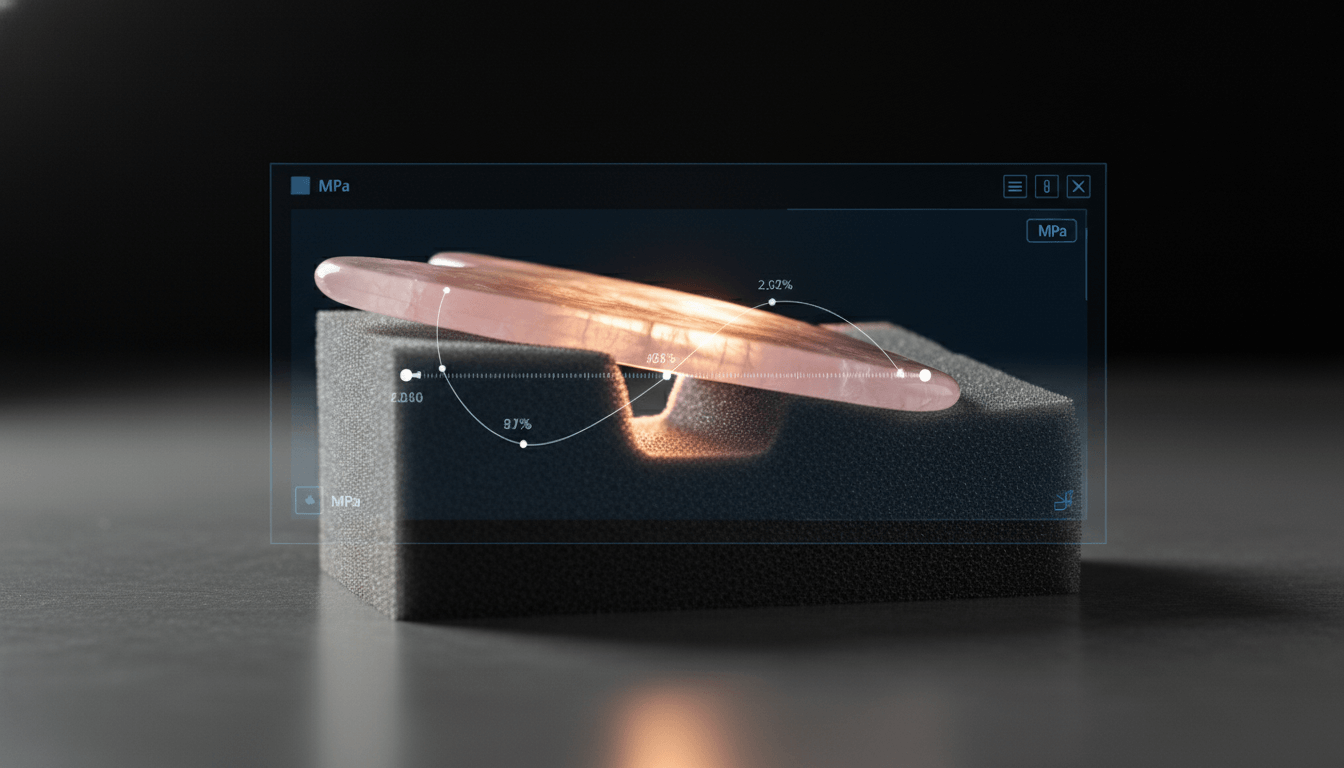

Weight Distribution and Pressure Points

Another important factor in gua sha wholesale packaging safety is weight distribution. Stone tools are relatively heavy for their size, which can create pressure points when stacked improperly. If weight is unevenly distributed in a carton, tools at the bottom may experience excessive compression, leading to fractures.

To address this, professional packaging systems are designed to distribute weight evenly across foam inserts or partitions. Vertical placement is often preferred because it reduces surface-to-surface contact and minimizes stress on thin edges.

Bulk Packaging Safety for Gua Sha Wholesale Orders

Large-Volume Carton Packaging Structure

In large gua sha wholesale orders, bulk packaging is the foundation of transport safety. Bulk packaging refers to how multiple units are packed together in cartons before palletization or container loading. The primary goal is to ensure stability while maximizing space efficiency.

In professional factory settings, bulk packaging is not random. It follows standardized internal layouts based on carton strength, tool size, and transport distance. Cartons are selected according to international shipping standards such as ASTM D5118, which defines corrugated box performance requirements

(https://www.astm.org).

Foam Insert Systems with Individual Compartments

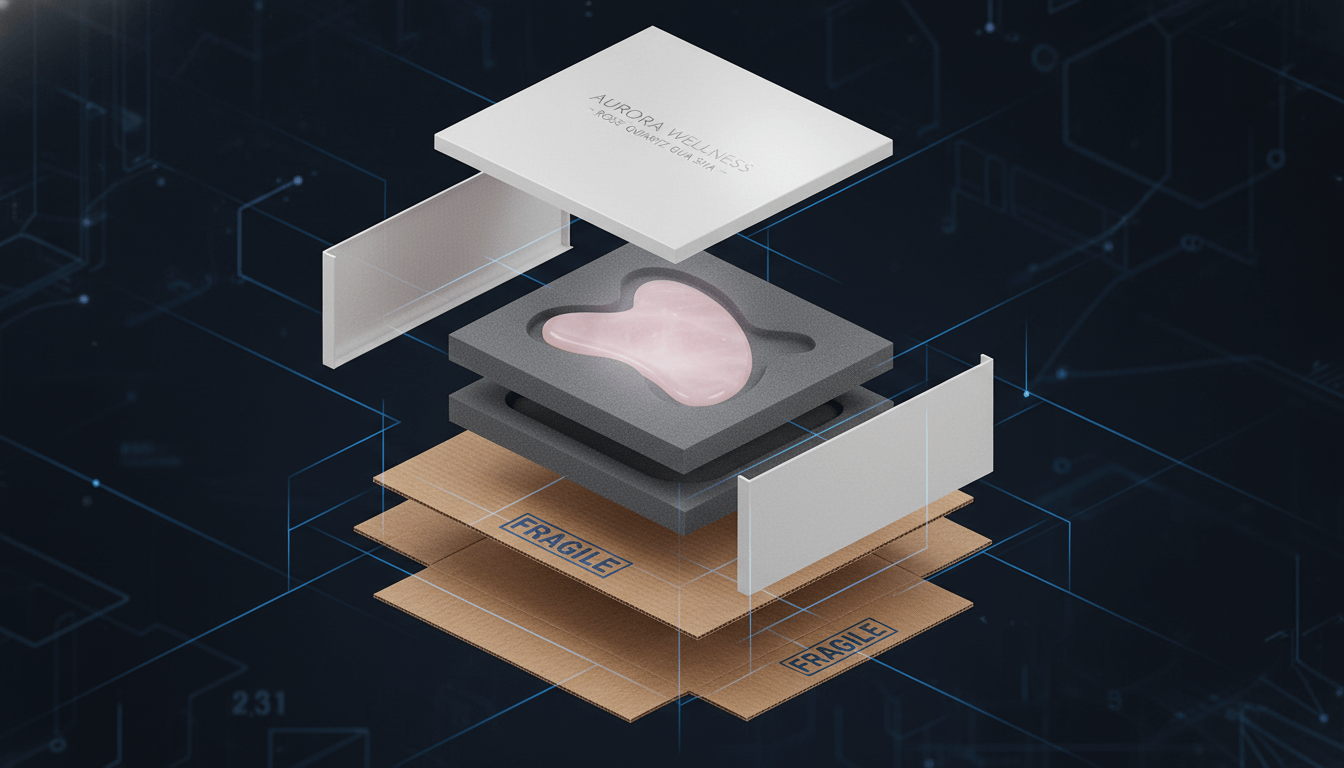

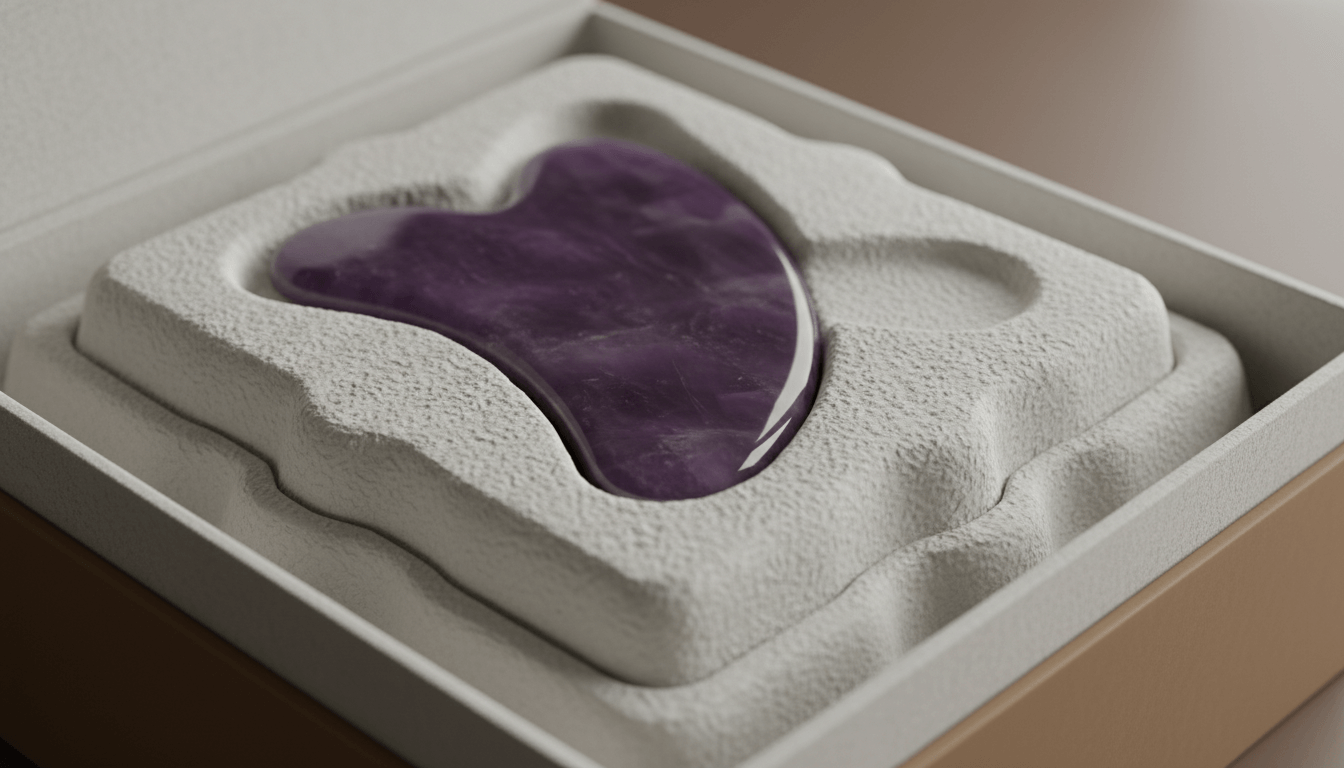

For our factory-level wholesale packaging, foam inserts are a core safety component. Each foam tray is designed with approximately 25 individual compartments, with each compartment holding one gua sha tool. The tools are placed vertically rather than horizontally, which significantly reduces the chance of edge impact.

This compartmentalized design ensures that each gua sha tool remains isolated throughout transport. Even under vibration or sudden movement, the foam absorbs shock and prevents tools from colliding with each other. Compared to loose packing or paper wrapping, foam inserts provide a much higher level of consistency and damage prevention.

In addition, foam density is carefully selected. Foam that is too soft may compress excessively, while foam that is too rigid may transfer shock directly to the stone. Balancing these properties is a key part of wholesale packaging engineering.

Carton Reinforcement and Sealing Methods

Beyond internal protection, the outer carton must also be reinforced. Double-wall corrugated cartons are commonly used for gua sha wholesale shipments, especially for international transport. These cartons resist compression and maintain shape under stacking pressure.

Sealing methods also matter. Industrial-grade tape or reinforced strapping helps prevent cartons from opening during handling. Improper sealing can lead to partial exposure of contents, increasing the risk of damage and contamination.

Individual Packaging Safety for Retail and Gift Sets

The Function of Individual Packaging in Wholesale

While bulk packaging protects gua sha tools during transit, individual packaging serves both protective and branding functions. In gua sha wholesale, individual packaging is often required for retail distribution, influencer kits, or direct-to-consumer fulfillment.

However, individual packaging must still be designed with transport safety in mind. A visually appealing box that lacks internal protection can become a liability when shipped in bulk. Therefore, structural design should always take precedence over aesthetics.

Internal Cushioning and Tool Stabilization

Inside individual boxes, gua sha tools should be stabilized to prevent movement. This is commonly achieved through molded inserts, foam pads, or custom paper pulp trays. The key principle is that the tool should not be able to shift inside the box when shaken.

From a professional standpoint, internal stabilization also reduces wear on surface polish. Repeated friction during shipping can dull the surface of polished stone, reducing perceived quality even if no visible cracks occur.

Matching Gift Box Size with Outer Carton Dimensions

One of the most overlooked aspects of gua sha wholesale packaging safety is the relationship between individual gift boxes and the outer carton. If the outer carton is too large relative to the gift boxes, internal movement becomes unavoidable.

In contrast, if the carton is too tight, excessive pressure may be applied to the boxes, deforming them or transferring stress to the stone tools inside. Therefore, carton dimensions must be precisely matched to the size and quantity of gift boxes. This balance prevents both collision and compression during transport.

Outer Carton Protection and Edge Reinforcement

Importance of Carton Edge Integrity

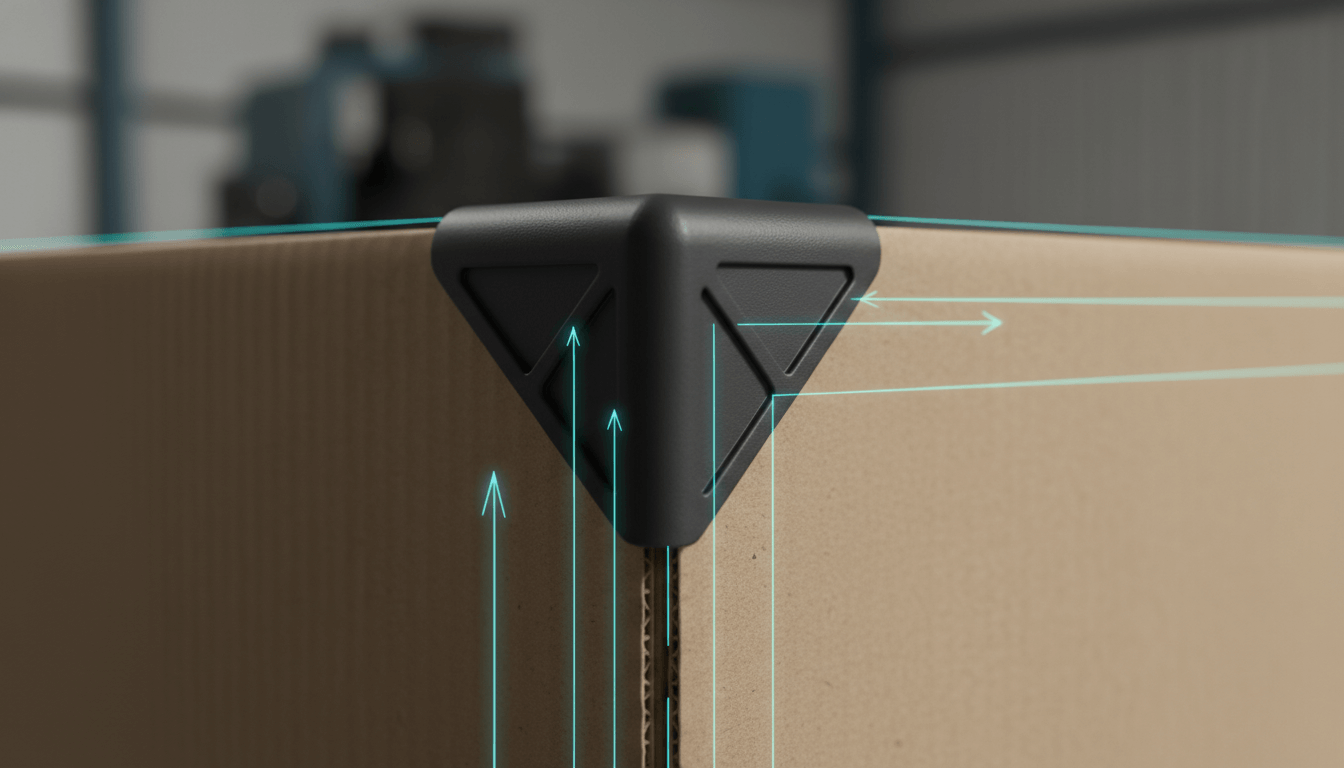

During shipping, cartons are frequently subjected to corner impacts and edge compression. These areas are structurally weaker than flat surfaces and are more likely to fail under stress. In gua sha wholesale, damage to outer cartons often leads to internal damage even if internal packaging is well designed.

To address this risk, protective corner reinforcements are commonly used. These reinforcements help maintain carton shape and absorb impact energy during handling.

Use of Plastic Triangular Corner Protectors

For higher-value shipments, plastic triangular corner protectors are often applied to the outer carton. These protectors shield the carton edges from direct impact and reduce deformation during stacking.

Although they add a small cost, corner protectors significantly reduce damage rates in long-distance shipping. According to logistics studies published by the Packaging Machinery Manufacturers Institute (PMMI), reinforced corners can reduce carton failure rates by up to 40%

(https://www.pmmi.org).

Palletized Transport for Large Gua Sha Wholesale Orders

When Palletization Becomes Necessary

For large gua sha wholesale orders, palletized transport is often required. Pallets improve handling efficiency, reduce manual contact, and lower the risk of cartons being dropped. However, palletization introduces its own set of safety considerations.

Improper pallet loading can cause cartons to shift, tilt, or collapse during transit. Therefore, pallet configuration must be carefully planned based on carton size, weight, and destination requirements.

Wrapping and Load Stabilization

Once cartons are placed on a pallet, the entire load is typically wrapped with a protective film. This wrapping serves multiple purposes. It prevents cartons from sliding, protects against dust and moisture, and maintains overall load stability.

In professional wholesale operations, stretch film is applied with controlled tension. Too little tension fails to stabilize the load, while excessive tension may crush cartons. The goal is to create a unified structure where cartons move as a single unit rather than independently.

Preventing Vibration and Load Shift

In addition to wrapping, slip sheets or anti-slip pads may be used between pallet layers. These materials increase friction and reduce vibration during transport. This is especially important for stone products like gua sha tools, which are sensitive to repeated micro-movements over long distances.

Quality Control and Packaging Testing Standards

Drop Testing and Vibration Testing

Packaging safety in gua sha wholesale is not based on assumptions. It is validated through testing. Drop tests simulate accidental drops during handling, while vibration tests replicate conditions inside trucks, ships, and aircraft.

Organizations such as ISTA provide standardized testing protocols that are widely recognized in international trade. Following these standards ensures that packaging systems perform consistently under real-world conditions

(https://ista.org).

Continuous Improvement Through Damage Feedback

Even with rigorous testing, real-world feedback remains essential. Professional factories track damage reports and analyze their root causes. If damage patterns emerge, packaging design is adjusted accordingly.

This continuous improvement approach ensures that packaging evolves alongside changes in logistics routes, carrier practices, and order volume. For wholesale buyers, working with manufacturers who actively refine their packaging systems is a key risk-reduction strategy.

Sustainability Considerations in Gua Sha Wholesale Packaging

Balancing Protection and Environmental Responsibility

As sustainability becomes a priority in the beauty industry, gua sha wholesale packaging must balance safety with environmental impact. Excessive packaging may reduce damage but increase waste, which can conflict with brand values.

Many manufacturers now explore recyclable foam alternatives, molded pulp inserts, and optimized carton sizing to reduce material usage without compromising protection. According to the Ellen MacArthur Foundation, optimized packaging design can reduce material use by up to 20% while maintaining performance

(https://ellenmacarthurfoundation.org).

Communicating Packaging Responsibility to Buyers

For wholesale buyers, transparent communication about packaging materials and safety measures builds trust. Explaining why certain materials are used, and how they protect fragile stone tools, helps buyers understand the value behind the cost.

This transparency is particularly important for premium gua sha brands that position themselves around quality, craftsmanship, and responsible sourcing.

Conclusion: Packaging Safety as a Strategic Advantage in Gua Sha Wholesale

In the competitive beauty and wellness market, gua sha wholesale success depends on more than product design and pricing. Packaging safety is a strategic element that protects inventory, reduces losses, and reinforces brand credibility. From bulk foam inserts with individual compartments to carefully matched gift box dimensions and palletized transport systems, every detail plays a role in ensuring safe delivery.

By understanding the principles outlined in this guide, wholesale buyers and brand owners can make informed decisions when selecting manufacturing partners and packaging solutions. Ultimately, investing in professional packaging safety is not an added cost but a long-term safeguard for product quality, customer satisfaction, and brand reputation.

As global demand for gua sha tools continues to grow, those who prioritize packaging safety will be better positioned to scale confidently and sustainably in the international market.