In the global beauty and wellness tools market, gua sha tools have gained significant popularity for their therapeutic benefits and aesthetic appeal. At Deyi Gems, our gua sha factory specializes in producing high-quality gua sha stones, rollers, and crystal tools for wholesalers and custom brands. Over years of production experience, we have observed a major shift in manufacturing methods — particularly the increasing adoption of CNC fully automated production.

CNC, or Computer Numerical Control, allows machines to shape materials with minimal human intervention. CNC machines work continuously, produce consistent shapes, and handle high-volume production demands. However, natural stones such as jade, rose quartz, or obsidian have internal variations that machines cannot detect, which poses challenges in automated production. This guide explores the technical advantages and limitations of CNC automation in gua sha manufacturing, with real data from Deyi Gems’ internal statistics.

What Is a Gua Sha Factory and the Role of CNC Automation

Gua Sha Factory Overview

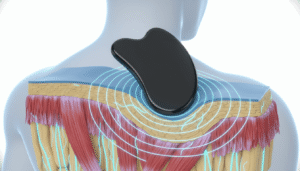

A gua sha factory produces tools used for facial massage, lymphatic drainage, and skin wellness. These tools are typically made from natural stones that require precise shaping, smoothing, and polishing. Traditionally, artisans handcraft each piece, adjusting for stone texture and internal fissures, which ensures tactile precision but limits scalability.

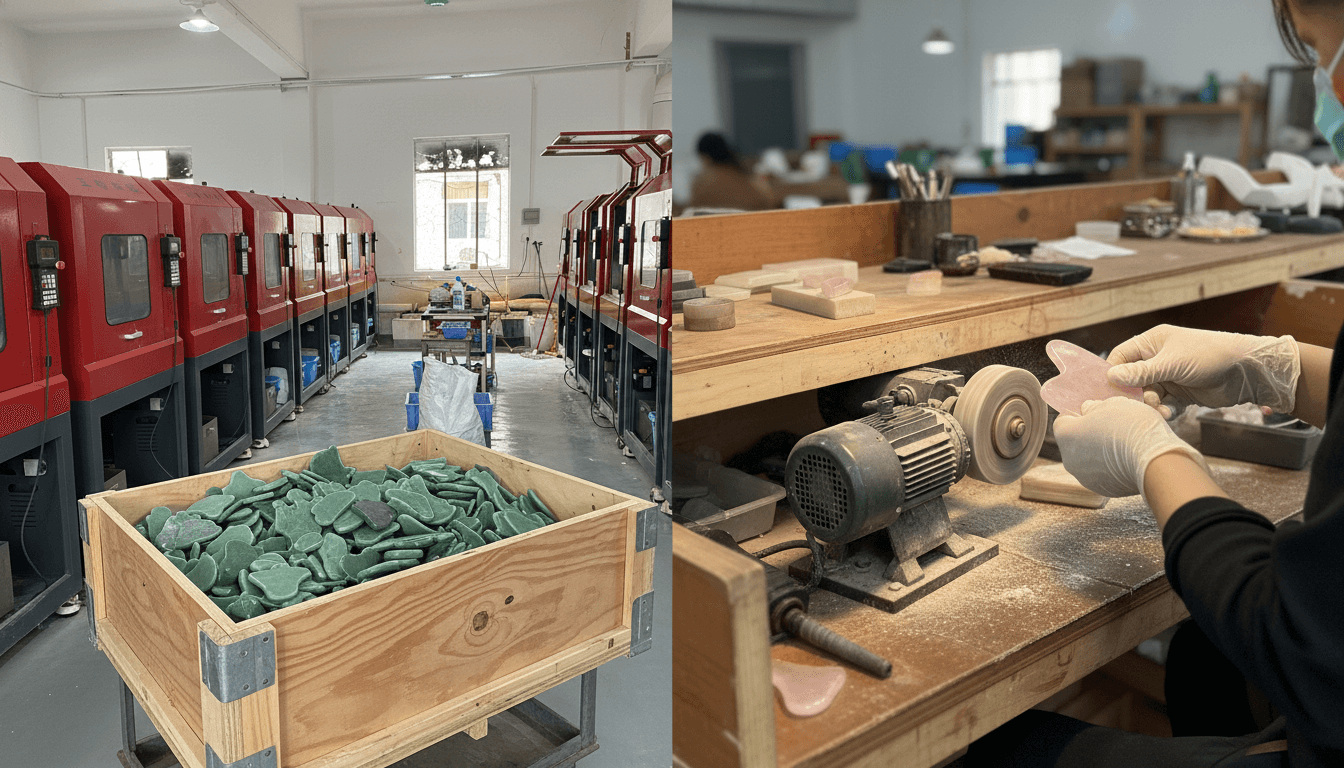

CNC Automation Integration

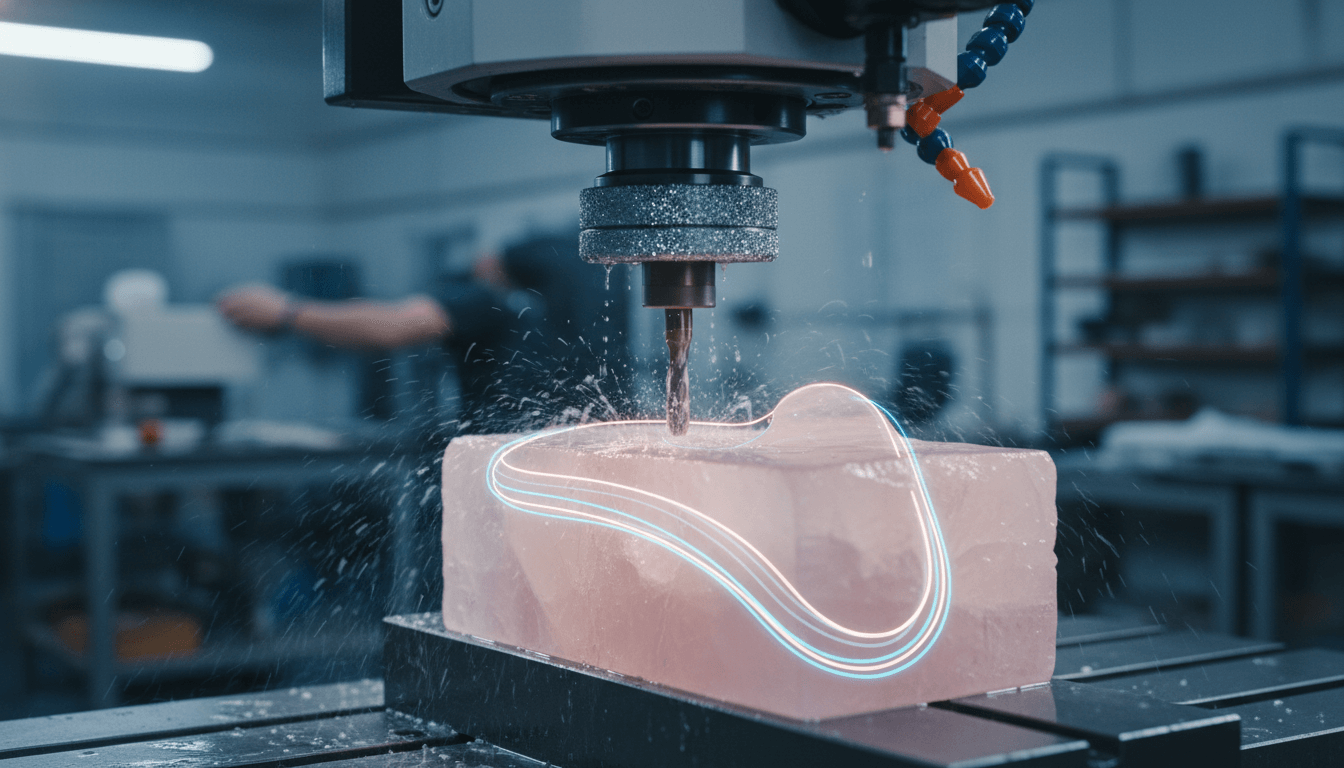

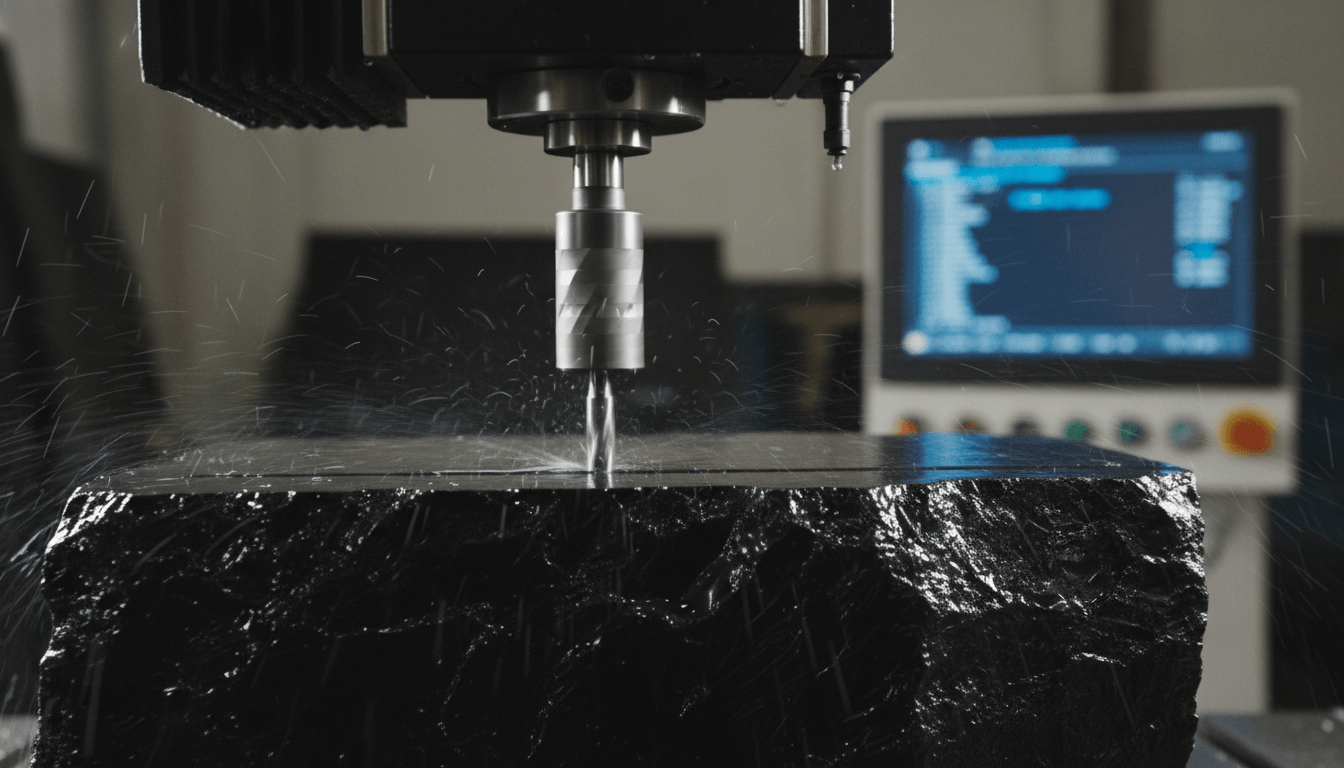

At Deyi Gems, CNC machines are integrated into production lines for rough shaping. Multi-axis routers and milling machines are programmed with precise digital tool paths, achieving consistent forms efficiently. After CNC shaping, skilled artisans perform final edge refinement and surface polishing to maintain premium quality.

Technical Advantages of CNC Production

Production Efficiency and Speed

- CNC machines run 20–22 hours per day; human workers require breaks and shifts.

- CNC shaping is ~32% faster than manual shaping.

- Example: 5,000 standard jade gua sha tools shaped in <4 days via CNC vs ~6 days manually.

Consistent Uniformity

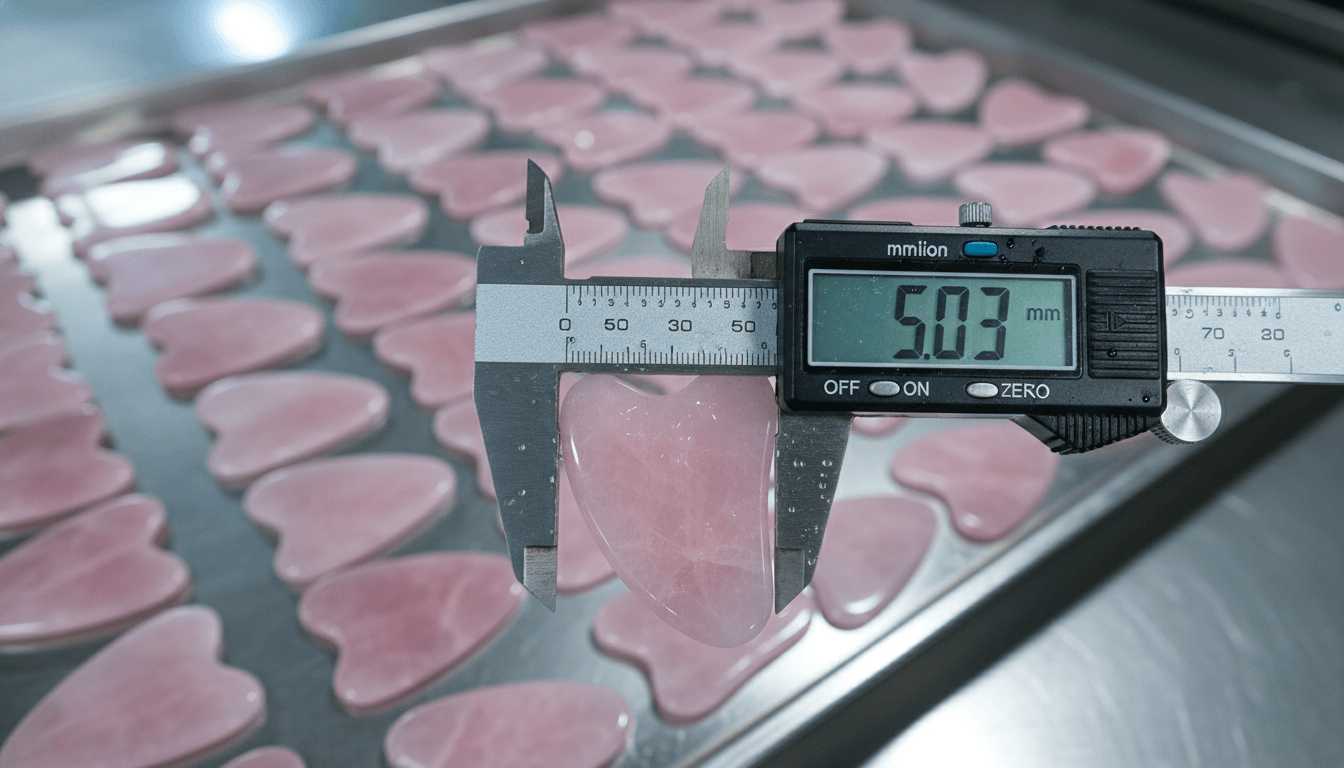

- CNC achieves 95% of pieces within ±0.5 mm size tolerance.

- Handcrafting achieves ~87% under the same checks.

- Uniformity ensures boxed sets and pre-packaged kits maintain consistent appearance and function.

Scalability and Continuous Running

- One operator can oversee 2–4 CNC machines; handcrafting requires one artisan per batch.

- Machines can produce up to 2,800 pieces/week per machine.

- Enables accurate planning for supply chain and inventory management.

Flexible Design and Rapid Prototyping

- CNC programming allows fast adjustments for new shapes.

- Prototype production: 2–3 days from concept to CNC sample vs 5–6 days manually.

Reduced Labor Requirements

- Labor hours for shaping tasks reduced by ~35%.

- Artisans can focus on polishing and finishing, where human touch is critical.

Technical Details of CNC Processes

CNC Parameters for Gua Sha Production

| Parameter | Typical Range / Notes |

|---|---|

| Machine Type | 3–5 axis CNC router or milling machine |

| Spindle Speed | 12,000–18,000 RPM (stone-dependent) |

| Feed Rate | 800–1,200 mm/min for standard gua sha |

| Cutting Depth | 0.3–0.5 mm per pass for delicate edges |

| Tool Type | Diamond-coated or tungsten carbide end mills |

| Cooling | Water or oil mist to reduce heat and prevent microcracks |

Stone-Specific Considerations

- Jade: Hard, dense; slower feed rates, higher spindle speed to avoid chipping.

- Rose Quartz: Medium hardness; moderate feed, gentle edge passes to reduce fractures.

- Obsidian: Brittle; shallower cutting depths, extra care to prevent cracking.

Hybrid Production Workflow

- CNC Rough Shaping → Uniform form, ±0.5 mm tolerance

- Preliminary Edge Smoothing → Hand finishing edges for comfort

- Fine Polishing → Buffing and polishing to achieve tactile smoothness

- Quality Control Inspection → Dimensional, surface, and structural checks

- Packaging → Only fully approved pieces shipped

Disadvantages of CNC Production

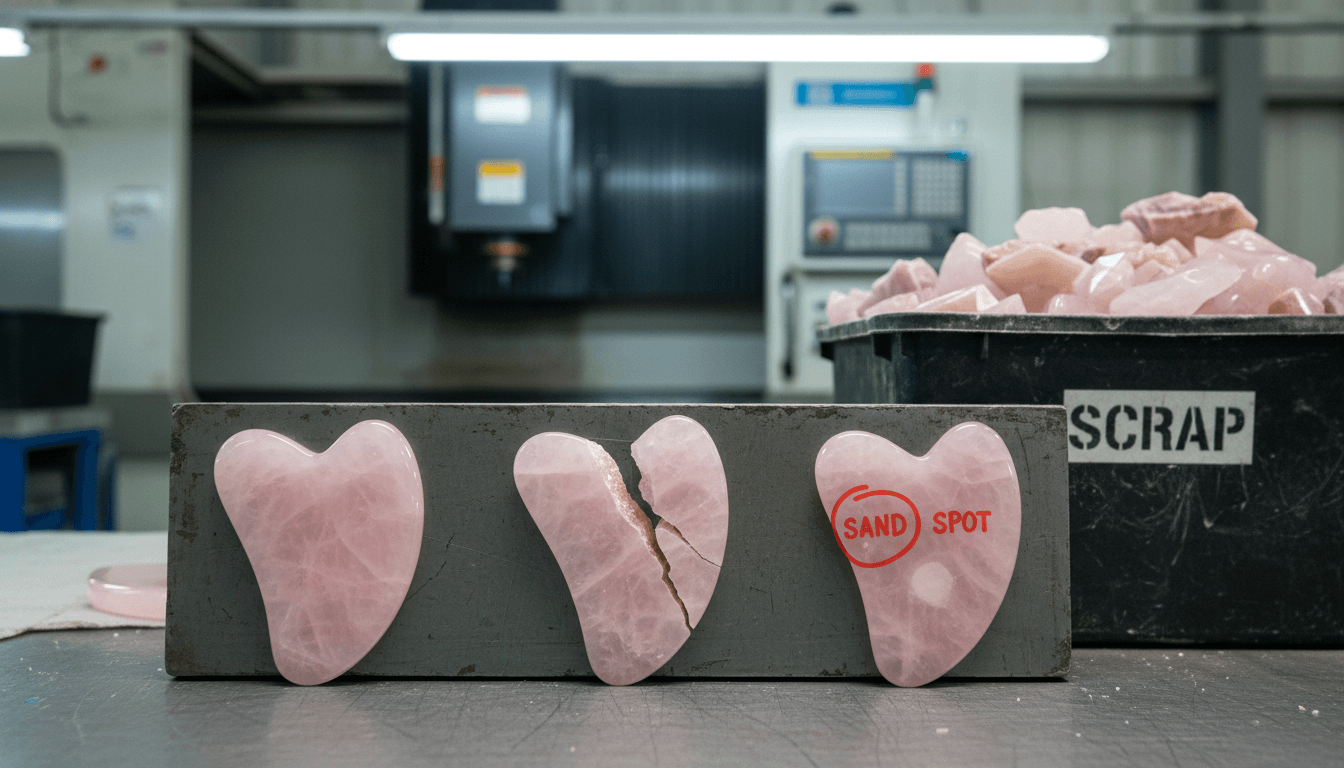

Internal Stone Flaws

- CNC cannot detect cracks, fissures, or sand spots invisible to the eye.

- Scrap rate: CNC 15–18% vs manual 8–12%, depending on stone and batch quality.

Tactile Quality

- Machines produce consistent shapes, but subtle edge smoothness and feel may be slightly inferior.

- Luxury brands often require hand-polished finishing for superior comfort.

Capital and Maintenance Costs

- CNC lines require several times the investment of manual workshops.

- Ongoing costs: maintenance, calibration, tool replacement, software upgrades.

Skilled Operators Required

- Operators must master G-code, tool path planning, and machine calibration.

- Mistakes can lead to wasted stones or suboptimal pieces.

Technology Dependence

- CNC systems rely on both hardware and software.

- Malfunctions can halt production; timely technical support is crucial.

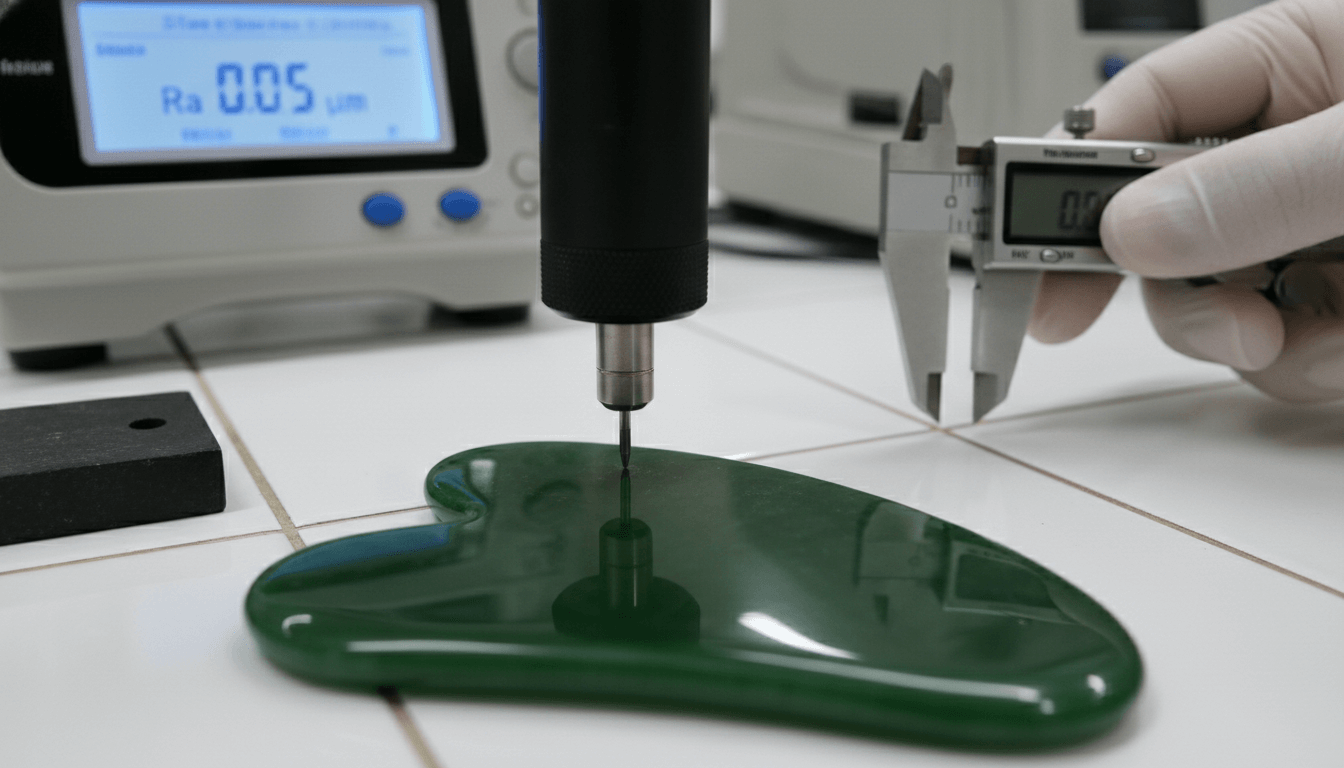

Quality Control and Inspection Standards

| QC Step | Measurement Tool | Standard / Target |

|---|---|---|

| Dimensional Accuracy | Digital calipers / CMM | ±0.5 mm |

| Surface Roughness | Ra tester | ≤0.8 µm |

| Edge Smoothness | Visual and tactile | No sharp edges |

| Structural Integrity | Optical scan / X-ray (optional) | No cracks/fissures |

| Polishing Finish | Visual & tactile | High gloss, uniform texture |

- Non-conforming pieces are manually corrected or recycled to maintain high quality.

Production Method Selection Based on Market Needs

- Wholesale / Large-volume orders: CNC rough shaping + hand finishing → efficient and consistent.

- Boutique / Luxury orders: Greater emphasis on manual refinement for tactile quality.

- Hybrid approach reduces total production time 25–30% while keeping scrap below 15%.

Conclusion: Smart CNC Use in Gua Sha Factories

CNC automation enhances speed, uniformity, and scalability in gua sha manufacturing:

- Production speed ↑ ~32%

- Size uniformity ↑ to 95%

- Labor hours for shaping ↓ ~35%

- Continuous output 20–22 hrs/day

Limitations: higher scrap rate, slightly reduced tactile feel, capital investment, and need for skilled operators.

Recommendation: Adopt a hybrid workflow—CNC for rough shaping, artisans for fine finishing—to balance efficiency, quality, and premium tactile experience. This ensures both wholesale and boutique customers receive gua sha tools that meet functional, aesthetic, and tactile standards. Deyi Gems’ internal production data confirms that this approach is both practical and sustainable for long-term growth.